Microencapsulated powder composition containing odorous oils and preparation technology thereof

The technology of a composition and microcapsule powder is applied in the field of microcapsule powder compositions containing peculiar smell oily components, and can solve the problems of single taking mode, bad taste, poor taste and oily taste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

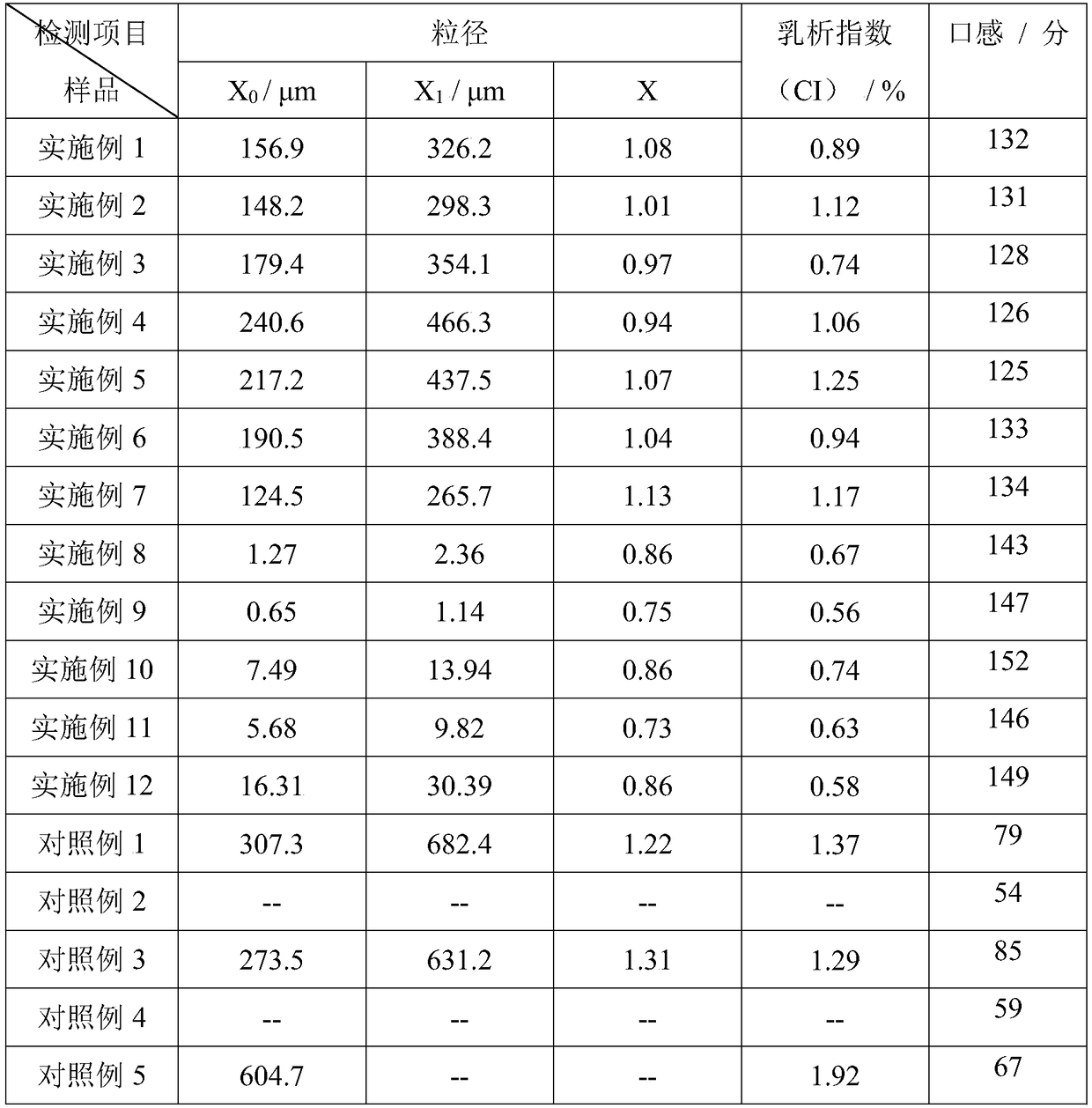

Examples

Embodiment 1

[0039] Recipe: 30g linseed oil, 200g dextrin, 30g orange peel oil

[0040] Process: at 60°C, mix and stir linseed oil and orange peel oil evenly to prepare an oil phase. At 50° C., slowly add the dextrin into the water and stir while adding until the dextrin is completely dissolved to prepare an aqueous phase. The mass ratio of water to dissolved raw material is 10:1. At 25° C. with a stirring speed of 100 rpm, the oil phase and the water phase were mixed and emulsified for 2 hours to obtain an emulsion. The emulsion was spray-dried to obtain microcapsule powder. The air inlet temperature for spray drying is 150°C and the outlet air temperature is 80°C

Embodiment 2

[0042] Recipe: 100g olive oil, 800g polyethylene glycol, 100g cinnamon oil

[0043] Process: Mix and stir olive oil and cinnamon oil evenly at 80°C to prepare an oil phase. Slowly add the polyethylene glycol into the water at 80°C, and stir while adding until the polyethylene glycol is completely dissolved to prepare an aqueous phase. The mass ratio of water to dissolved raw material was 19:1. When the stirring speed is 500 rpm at 25°C, the oil phase and the water phase are mixed and emulsified for 0.5 hour to obtain an emulsion, and the emulsion is made into a reprocessed emulsion by colloid grinding. The reprocessed emulsion was spray-dried to obtain microcapsule powder. The air inlet temperature for spray drying is 165°C and the outlet air temperature is 90°C.

Embodiment 3

[0045] Recipe: 50g chia seed oil, 600g gelatin, 10g clove oil, 25g stevioside

[0046] Process: at 50°C, mix and stir chia seed oil and clove oil evenly to prepare an oil phase. After mixing the gelatin and stevioside evenly at 50°C, slowly add it into water, and stir while adding until the gelatin and stevioside are completely dissolved to prepare a water phase. The mass ratio of water to dissolved raw material is 10:1. At 25°C, when the stirring speed is 1000rpm, the oil phase and the water phase are mixed and emulsified for 1 hour to obtain an emulsion, and the emulsion is homogenized under a high pressure of 100MPa to prepare a reprocessed emulsion. The reprocessed emulsion was spray-dried to obtain microcapsule powder. The inlet air temperature for spray drying is 180°C, and the outlet air temperature is 100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com