Method for preparing formaldehyde adsorbent by wine making residues

A formaldehyde adsorption and residue technology, applied in separation methods, chemical instruments and methods, gas treatment, etc., can solve the problems of high cost of use and poor versatility, and achieve the effects of optimizing adsorption conditions, realizing economic cycle development and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of method that utilizes grape wine residue to prepare formaldehyde adsorbent described in the present embodiment, concrete steps are as follows:

[0020] (1) Processing raw materials: select waste grape wine residues as raw materials, and clean them with running water;

[0021] (2) Drying: place the cleaned raw materials in a constant temperature drying oven at 60°C and 6.67×10 Pa to dry to constant weight;

[0022] (3) Cutting: the raw material after step (2) is dried is cut into the segment that length is 3cm with scissors;

[0023] (4) Cooking: boil the cut raw material section in step (3) in boiling water at 80°C for 20 minutes;

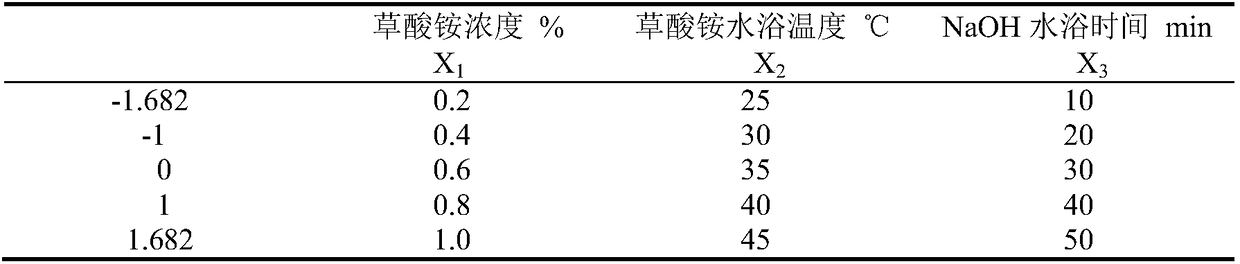

[0024] (5) Soaking in ammonium oxalate: cool the cooked raw materials in step (4) to 20° C., soak in ammonium oxalate solution with a concentration of 1%, and place in a constant temperature water bath at 40° C. for 20 minutes.

[0025] (6) Soaking in lye: place the small section of the raw material in step (5) in a water bath in ...

Embodiment 2

[0029] A kind of method that utilizes grape wine residue to prepare formaldehyde adsorbent described in the present embodiment, concrete steps are as follows:

[0030] (1) Processing raw materials: select waste grape wine residues as raw materials, and clean them with flowing water;

[0031] (2) Drying: place the cleaned raw materials in a constant temperature drying oven at 70°C and 6.67×10 Pa to dry to constant weight;

[0032] (3) shearing: the raw material after step (2) is dried is cut into the segment that length is 5cm with scissors;

[0033] (4) Cooking: boil the cut raw material section in step (3) in boiling water at 120°C for 40 minutes;

[0034] (5) Soaking in ammonium oxalate: cool the cooked raw materials in step (4) to 33° C., soak in ammonium oxalate solution with a concentration of 1.5%, and place in a constant temperature water bath at 60° C. for 40 minutes.

[0035] (6) Soaking in lye: place the small section of the raw material in the water bath in step (...

Embodiment 3

[0039] A kind of method that utilizes grape wine residue to prepare formaldehyde adsorbent described in the present embodiment, concrete steps are as follows:

[0040] (1) Processing raw materials: select waste grape wine residues as raw materials, and clean them with flowing water;

[0041] (2) Drying: place the cleaned raw materials in a constant temperature drying oven at 65°C and 6.67×10 Pa to dry to constant weight;

[0042] (3) shearing: the dried raw material of step (2) is cut into a segment of 4 cm in length with scissors;

[0043] (4) Cooking: boil the cut raw material section in step (3) in boiling water at 100°C for 30 minutes;

[0044] (5) Soaking in ammonium oxalate: cool the cooked raw materials in step (4) to 25° C., soak in ammonium oxalate solution with a concentration of 1.2%, and place in a constant temperature water bath at 50° C. for 30 minutes.

[0045] (6) Soaking in lye: place the small section of the raw material in step (5) in a water bath in a sod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com