Preparation method of anti-seepage cement slurry for landfill base

An anti-seepage water and base technology, which is applied in the field of preparation of anti-seepage cement slurry for landfill bases, can solve the problems of many pores, reduced surface activity of blast furnace water slag particles, densification of difficult cement particles, etc. Effects of pollutants, improving compatibility, improving compactness and stone rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

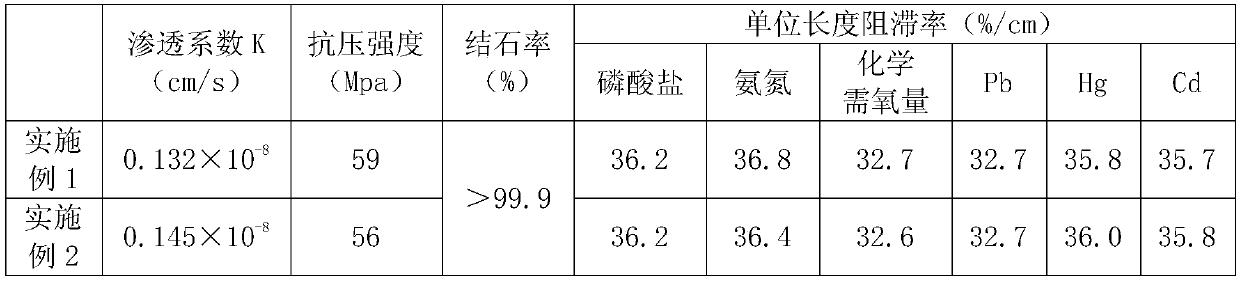

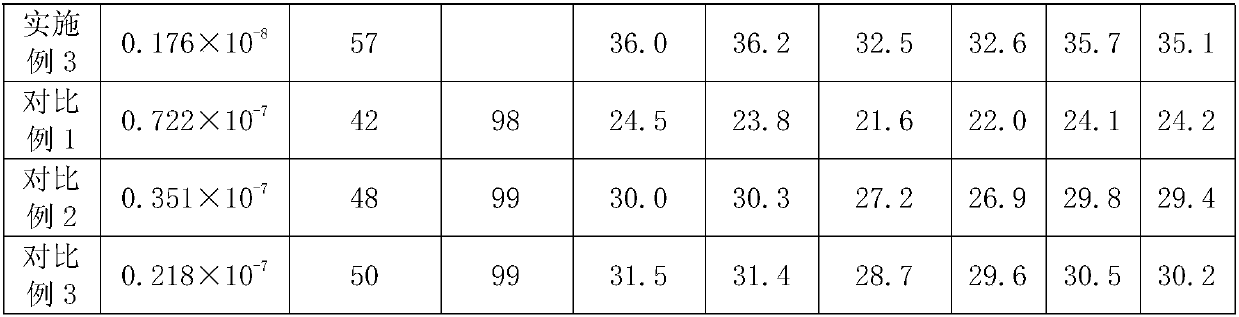

Examples

Embodiment 1

[0044] According to the metering ratio, add 8 parts of 1mol / L sodium phosphate solution to 120 parts of blast furnace water slag obtained by water quenching for grinding and stirring; then add 4 parts of dodecyl trimethyl ammonium bromide and 6 parts of hydroxy silicone oil to it (viscosity 400cps) continue to mix and stir; finally add 5 parts of polyacrylamide to it and mix and stir to obtain modified blast furnace slag for later use.

[0045] The bentonite was calcined at 350°C for 2 h, and after natural cooling, the modified bentonite was obtained by pulverizing and grinding.

[0046] According to the metering ratio, 50 parts of modified bentonite, 6 parts of silicone defoamer, and 5 parts of polycarboxylate water reducer were mixed and stirred to obtain the first premix; 10 parts of oleoyl monoethanolamine, 80 parts of modified blast furnace slag were mixed and stirred. , 100 parts of ordinary Portland cement, 30 parts of gypsum, and 180 parts of water are mechanically sti...

Embodiment 2

[0048] According to the metering ratio, add 12 parts of 1.5mol / L sodium dihydrogen phosphate solution to 150 parts of blast furnace water slag obtained by water quenching and grind and stir; then add 6.5 parts of tetrabutylammonium bromide and 5 parts of hydroxysilicone oil ( Viscosity 2000cps), continue to mix and stir; finally, add 11 parts of polyacrylamide to it and mix and stir to obtain modified blast furnace slag for later use.

[0049] The bentonite was calcined at 290°C for 3.5 h, and after natural cooling, the modified bentonite was obtained by pulverizing and grinding.

[0050] According to the metering ratio, 44 parts of modified bentonite, 8 parts of silicone defoamer, and 5 parts of polycarboxylate water reducer were mixed and stirred to obtain the first premix; 22 parts of oleoyl monoethanolamine, 95 parts of modified blast furnace slag were mixed and stirred. , 85 parts of ordinary Portland cement, 15 parts of gypsum, and 210 parts of water are mechanically s...

Embodiment 3

[0052] Add 7 parts of 1 mol / L dipotassium hydrogen phosphate solution to 125 parts of blast furnace water slag obtained by water quenching according to the metering ratio for grinding and stirring; then add 4 parts of cetyltrimethylammonium bromide and 3 parts of Hydroxy silicone oil (viscosity 200cps) continued to be mixed and stirred; finally, 10 parts of polyacrylamide was added to it, and the mixture was fully mixed and stirred to obtain modified blast furnace slag for use.

[0053] The bentonite was calcined at 380°C for 2 h, and after natural cooling, the modified bentonite was obtained by pulverizing and grinding.

[0054] According to the metering ratio, 50 parts of modified bentonite, 8 parts of silicone defoamer, and 9 parts of polycarboxylate water reducer were mixed and stirred to obtain the first premix; 18 parts of oleoyl monoethanolamine, 90 parts of modified blast furnace slag were mixed and stirred. , 80 parts of ordinary Portland cement, 25 parts of gypsum, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com