Multi-component 3D printing extruded material

A 3D printing and extrusion molding technology, applied in the field of 3D printing materials, can solve the problems of single product form and cannot meet various process requirements, and achieve the effect of small volume change, improved thermal shock stability, and reduced shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

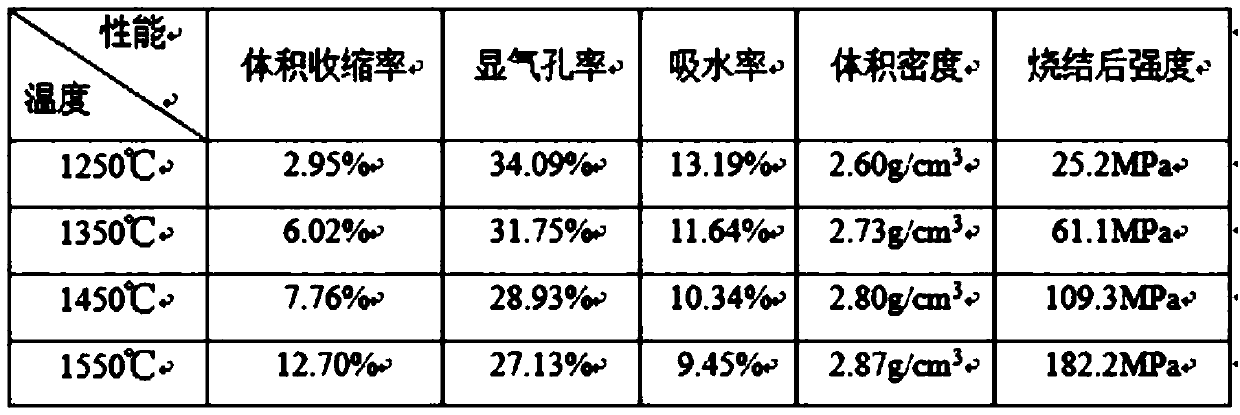

Embodiment 1

[0030] An extrusion molding material for 3D printing, the molding material is designed as a two-component material, the two-component material is composed of A component and B component, and A component and B component are respectively input into the printer through the action of air pump pressure The mixing bin, after mixing evenly, prepares a two-component mixture for 3D printing;

[0031] Wherein, the A component and the B component are prepared by the following method, in parts by weight:

[0032] In the first step, take 200 parts of alumina powder with a particle size of 0.5-1mm, 350 parts of alumina powder with a particle size of 30-200 μm, 100 parts of alumina powder with a particle size of 5-10 μm, and 350 parts of alumina powder with a particle size of 1.2-3 μm;

[0033] In the second step, the above four powders weighed are added to a ball mill tank with a rotating speed of 200 rpm and ball milled for 1 hour to obtain a mixed powder material;

[0034] The third step...

Embodiment 2

[0038] An extrusion molding material for 3D printing, the molding material is designed as a three-component material, the three-component material is composed of A component, B component and C component, A component, B component and C component The parts are input into the mixing chamber of the printer through the pressure of the air pump, and after mixing evenly, a three-component mixture for 3D printing is prepared;

[0039] Wherein, the A, B, and C components are prepared by the following method, in parts by weight:

[0040] In the first step, take 200 parts of alumina powder with a particle size of 0.5-1mm, 300 parts of alumina powder with a particle size of 30-200 μm, 200 parts of alumina powder with a particle size of 5-10 μm, and 300 parts of alumina powder with a particle size of 1.2-3 μm;

[0041] In the second step, the above four powders weighed are added to a ball mill tank with a rotating speed of 300 rpm and ball milled for 1 hour to obtain a mixed powder materia...

Embodiment 3

[0047] An extrusion molding material for 3D printing, the molding material is designed as a four-component material, the four-component material is composed of A component, B component, C component and D component, A component, B group Components, C and D components are respectively input into the mixing bin of the printer through the pressure of the air pump, and after mixing evenly, a multi-component mixture for 3D printing is prepared;

[0048] Wherein, the A, B, C, and D components are prepared by the following method, in parts by weight:

[0049] In the first step, take 200 parts of alumina powder with a particle size of 0.5-1mm, 350 parts of alumina powder with a particle size of 30-200 μm, 100 parts of alumina powder with a particle size of 5-10 μm, and 350 parts of alumina powder with a particle size of 1.2-3 μm;

[0050] In the second step, the above four powders weighed are added to a ball mill tank with a rotating speed of 300 rpm and ball milled for 1 hour to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com