A kind of preparation method of amniotic membrane fixer

A technology of fixator and amniotic membrane, which is applied in the fields of prosthesis, ophthalmic treatment, medical science, etc., can solve the problems of inability to meet individual requirements, hard PMMA material, and difficulty in matching patients, so as to treat ocular surface damage and meet individual needs. Chemical requirements, the effect of high hydrophilic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0031] Embodiment 2 The mold of the amniotic membrane fixer

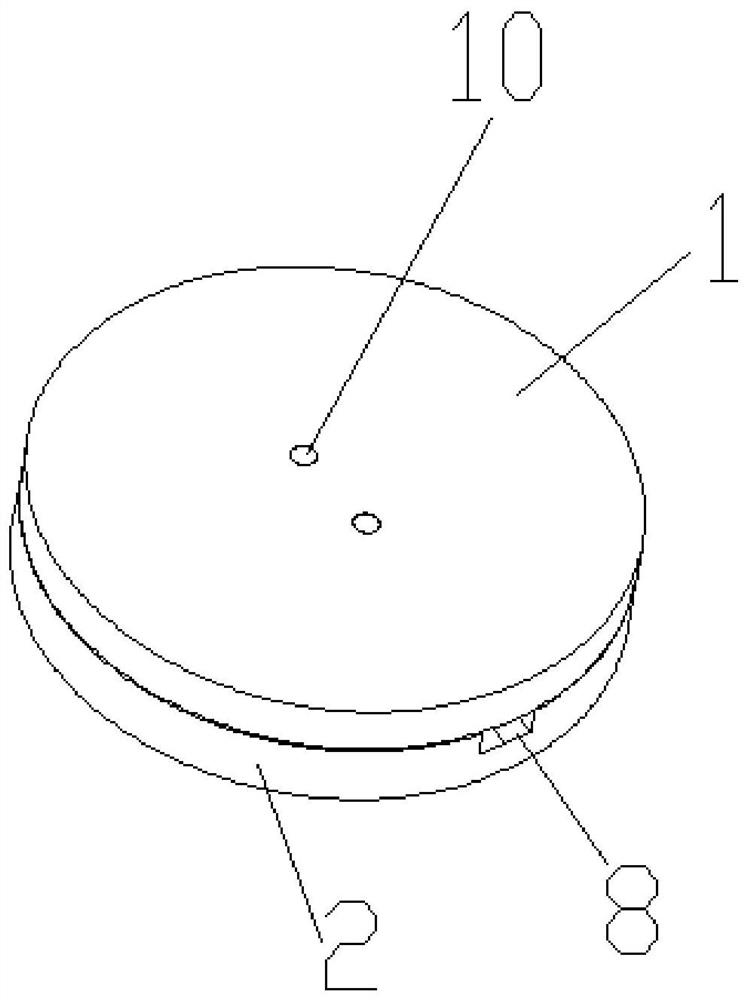

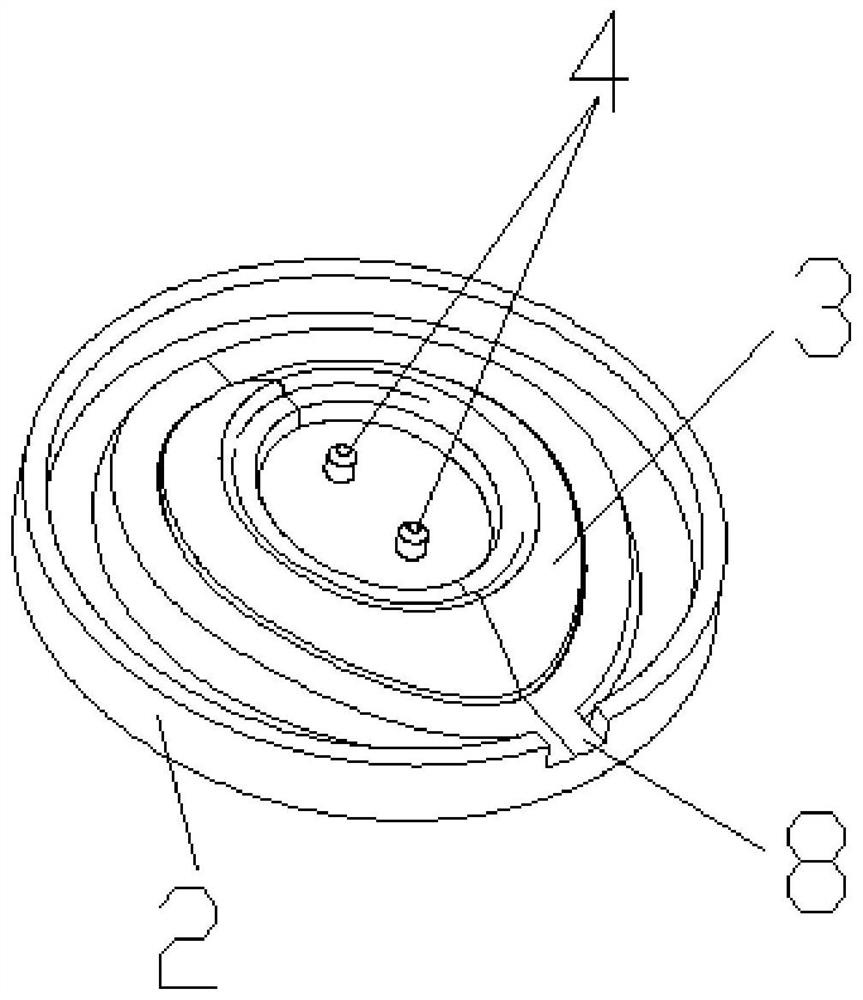

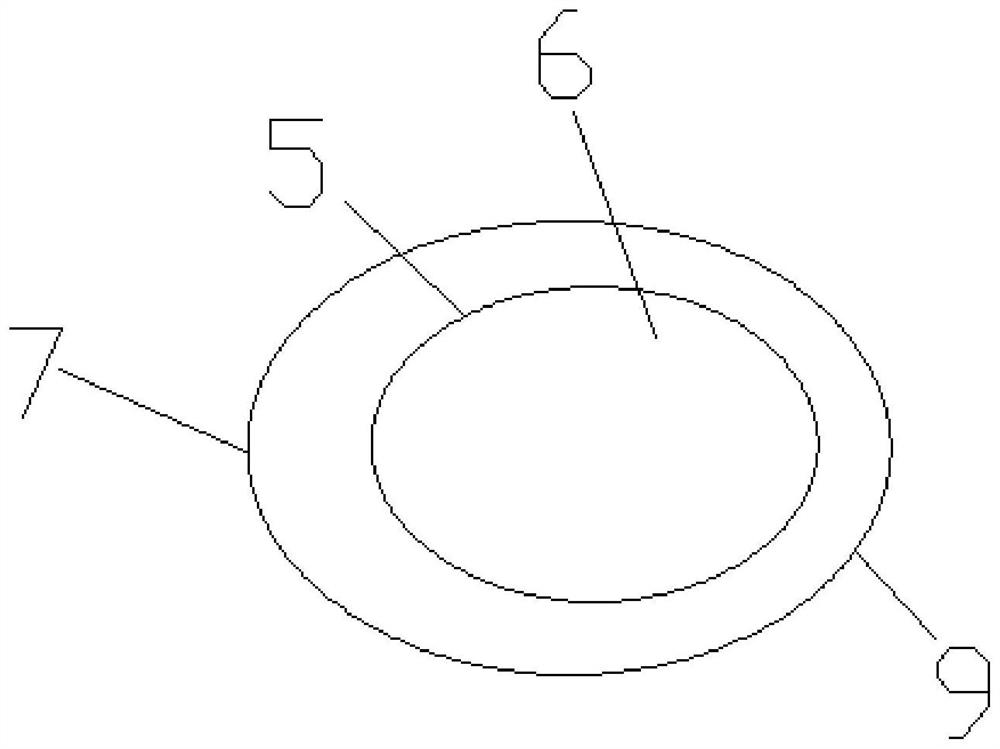

[0032] An embodiment of the mold of the amniotic membrane fixer in the present invention, as figure 1 and 2 As shown, it includes an upper mold 1 and a lower mold 2, the upper mold 1 is provided with an upper core (not shown in the figure), the lower mold 2 is provided with a lower core 3, and the lower core 3 is provided with a There is a protrusion 4, and the upper core is provided with a groove 10 that matches the protrusion 4, so that the upper mold clamping 1 and the lower clamping mold 2 can be molded more firmly, and the formed product—the size of the amniotic membrane fixer More standard and unified, after the upper clamping mold 1 and the lower clamping mold 2 are connected together, the middle parts of the upper mold core and the lower mold core 3 are tightly connected to form the amniotic membrane fixer (see image 3 ), the inner ring 5 in the middle of the mold, the amniotic membrane fixer correspondin...

Embodiment 3

[0033] The preparation method of embodiment 3 amniotic membrane fixer

[0034] A kind of embodiment of the preparation method of amniotic membrane fixer of the present invention, comprises the steps:

[0035] (1) Dissolving hydroxyethyl methacrylate in water, adding macromolecular crosslinking agent polyethylene glycol diacrylate, initiator 4-chlorobenzophenone and glycerin in sequence, vigorously shaking and mixing to obtain a mixture;

[0036] (2) Ultrasonic method is used to remove the air bubbles in the mixture obtained in step (1), and then injected into the amniotic membrane fixer mold of Example 2;

[0037] (3) Place the mold of the amniotic membrane fixer in a UV curing machine, irradiate with ultraviolet light for 5 minutes, and cure and form;

[0038] (4) Take out the molded amniotic membrane fixer from the mold, soak and wash it with clean water for 4 days, take it out, and dry it to obtain the amniotic membrane fixer. See Example 1 for its structure.

[0039] Whe...

Embodiment 4

[0040] The preparation method of embodiment 4 amniotic membrane fixer

[0041] A kind of embodiment of the preparation method of amniotic membrane fixer of the present invention, comprises the steps:

[0042] (1) Dissolve hydroxyethyl methacrylate in water, and then add the mixture of macromolecular crosslinking agent polyethylene glycol diacrylate and ethylene glycol dimethacrylate (polyethylene glycol diacrylate and dimethyl The mass ratio of ethylene glycol acrylate is 1:2), initiator benzoin dimethyl ether and glycerin, vigorously shake and mix to obtain a mixture;

[0043] (2) Ultrasonic method is used to remove the air bubbles in the mixture obtained in step (1), and then injected into the amniotic membrane fixer mold of Example 2;

[0044](3) Place the mold of the amniotic membrane fixer in a UV curing machine, irradiate with ultraviolet light for 10 minutes, and cure and form;

[0045] (4) Take out the molded amniotic membrane fixer from the mold, soak and wash it wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com