A surface-modified nano-silica nanofluid for enhanced oil recovery

A technology for surface modification of nano- and nano-silica, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the cumbersome steps of modifying nano-silica, inconvenient promotion and application of industrial products, and crude oil recovery Low efficiency and other problems, to achieve the effect of enhanced oil recovery, low environmental requirements for synthesis, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

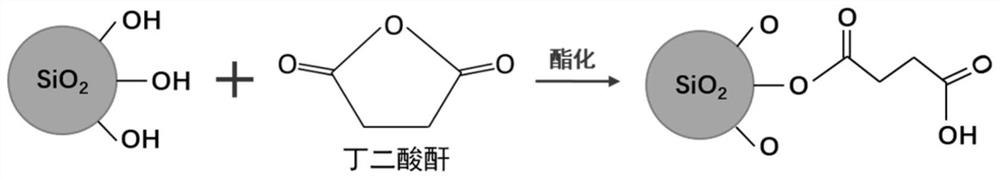

[0036] The preparation method of the surface-modified nano silica modified by the acid anhydride comprises the following steps:

[0037] 1) Add the hydrophilic surface hydroxyl nano-silica into the organic solvent, the mass percentage of the hydrophilic surface hydroxyl nano-silica is 1-1.5%, and the organic solvent is toluene, cyclohexane, tetrahydrofuran or N,N- One of the dimethylformamides, mechanically stirred for 30 minutes at a speed of 700-800 rpm, and then ultrasonically dispersed at 50°C for 1-2 hours using an ultrasonic cleaner to ensure the stability of nano-silica in organic solvents Dispersion effect, to obtain nano-silicon dioxide stock solution;

[0038] 2) adding the acid anhydride organic matter into the nano-silica stock solution, the mass ratio of the acid anhydride organic matter to the hydrophilic surface hydroxyl nano-silica in the nano-silica stock solution is 1.5-2:1, at room temperature 25°C Under magnetic stirring for 12 hours, the rotation speed is...

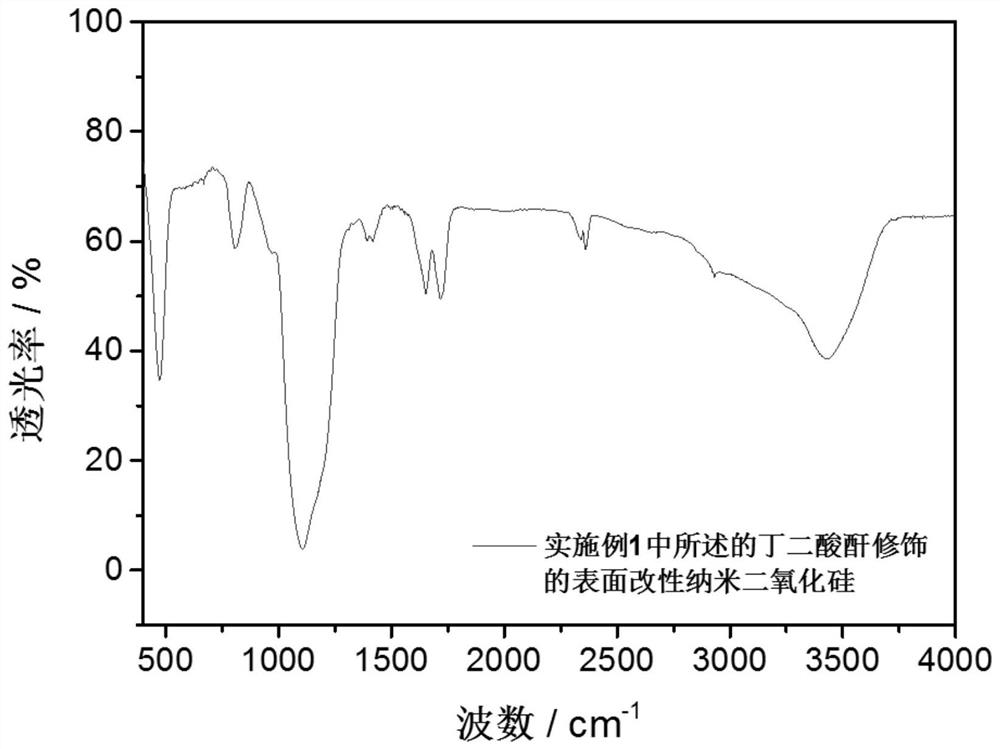

Embodiment 1

[0044] 2g particle size 15nm, specific surface area 380m 2 / g of hydrophilic surface hydroxyl nano-silica dispersed in 200ml N,N-dimethylformamide, mechanically stirred for 30 minutes at a speed of 700 rpm, and then ultrasonically dispersed at 50°C for 1 hour using an ultrasonic cleaner , to obtain nano silica stock solution.

[0045] Weigh 3 g of succinic anhydride and add it to the nano-silica stock solution, and magnetically stir for 12 hours at a room temperature of 25° C. at a speed of 700 rpm to obtain a succinic anhydride surface-modified nano-silica reaction solution.

[0046] Put the succinic anhydride surface-modified nano-silica reaction solution into a centrifuge at a speed of 8,500 rpm, centrifuge at a high speed for 15 minutes, take out the upper layer liquid and collect the centrifuged product, and centrifuge the upper layer liquid again at a high speed for 15 minutes. The rotation speed was 8500 rpm, the upper liquid was poured off, and the centrifuged product...

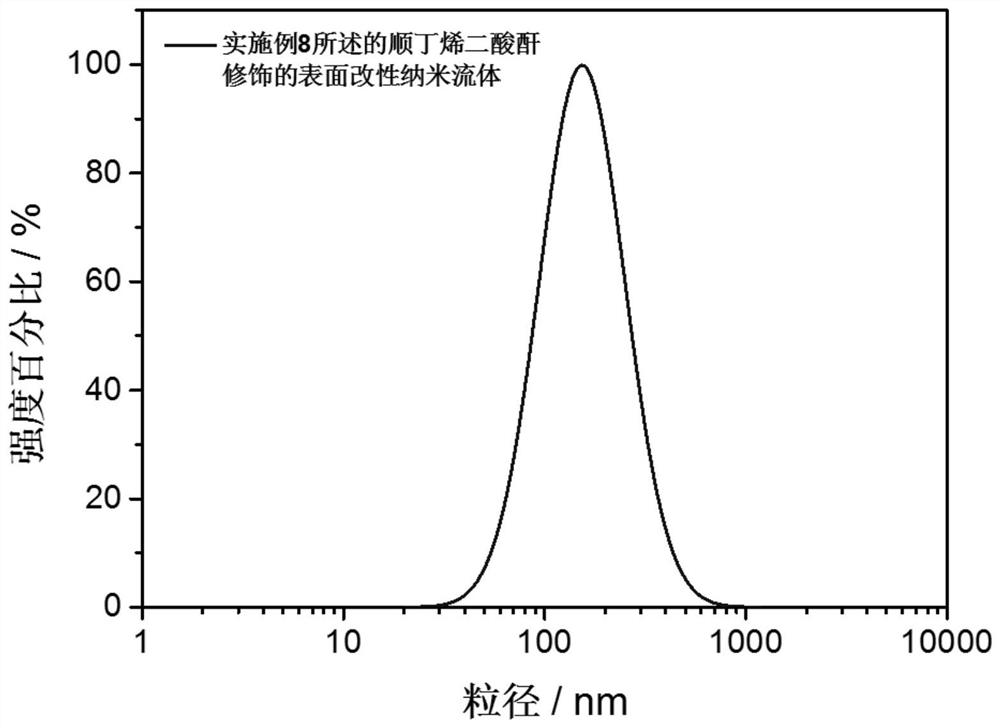

Embodiment 2

[0053] 3g particle size 20nm, specific surface area 200m 2 / g of hydrophilic surface hydroxyl nano-silica dispersed in 300ml of cyclohexane, mechanically stirred for 30 minutes at a speed of 750 rpm, and then ultrasonically dispersed at 50°C for 1 hour using an ultrasonic cleaner to obtain nano-silica Silicon stock solution.

[0054] Weigh 5 g of maleic anhydride and add it to the nano-silica stock solution, and magnetically stir for 12 hours at a room temperature of 25° C. at a speed of 750 rpm to obtain a maleic anhydride surface-modified nano-silica reaction solution.

[0055] Put the maleic anhydride surface-modified nano-silica reaction solution into a centrifuge at a speed of 8500 rpm, centrifuge at a high speed for 15 minutes, take out the upper layer liquid and collect the centrifuged product, and perform high-speed centrifugation on the upper layer liquid again for 15 minutes. Minutes, the rotation speed is 8500 rev / min, the upper layer liquid is poured off, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com