High-carbon high-vanadium wear-resistant steel and preparation method thereof

A wear-resistant steel and high-vanadium technology is applied in the field of high-carbon and high-vanadium wear-resistant steel and the preparation of high-carbon and high-vanadium wear-resistant steel. Wide range, improved wear resistance and toughness, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

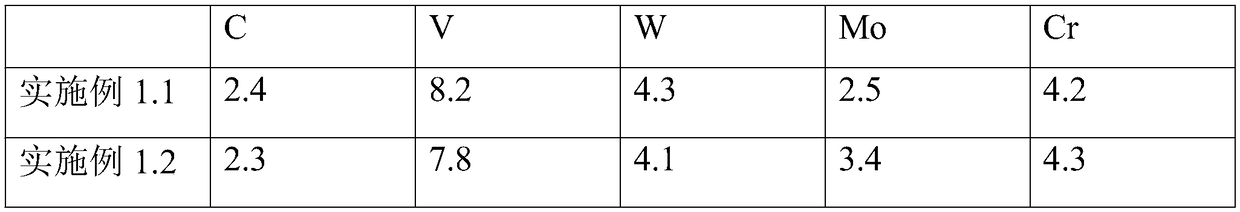

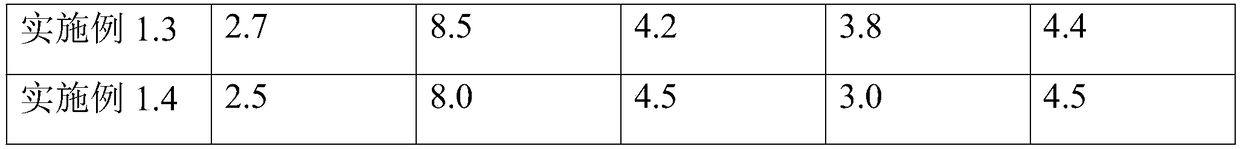

[0041] This example involves a group of high-carbon and high-vanadium high-speed steel, the chemical composition of which is shown in Table 1.1:

[0042]Table 1.1 Example 1 high-carbon high-vanadium high-speed steel, its chemical composition is shown in Table 1.1:

[0043]

[0044]

[0045] Adopt the following preparation steps:

[0046] a. Prepare molten steel according to the above chemical composition requirements: smelt molten steel with qualified components through a smelting furnace, and then use the method of refining outside the furnace to remove inclusions and improve the purity of molten steel.

[0047] b. Steel ingots were prepared by spraying technology, and steel ingots with a diameter of 350-550 mm were prepared; the degrees of superheat in Examples 1.1-1.4 were set to 200, 210, 230 and 250° C. in sequence.

[0048] c. Steel ingot annealing: the steel ingot is annealed by waste heat annealing, kept at 800°C for 1-4h, then cooled to 700°C at a rate of 10°C / ...

Embodiment 2

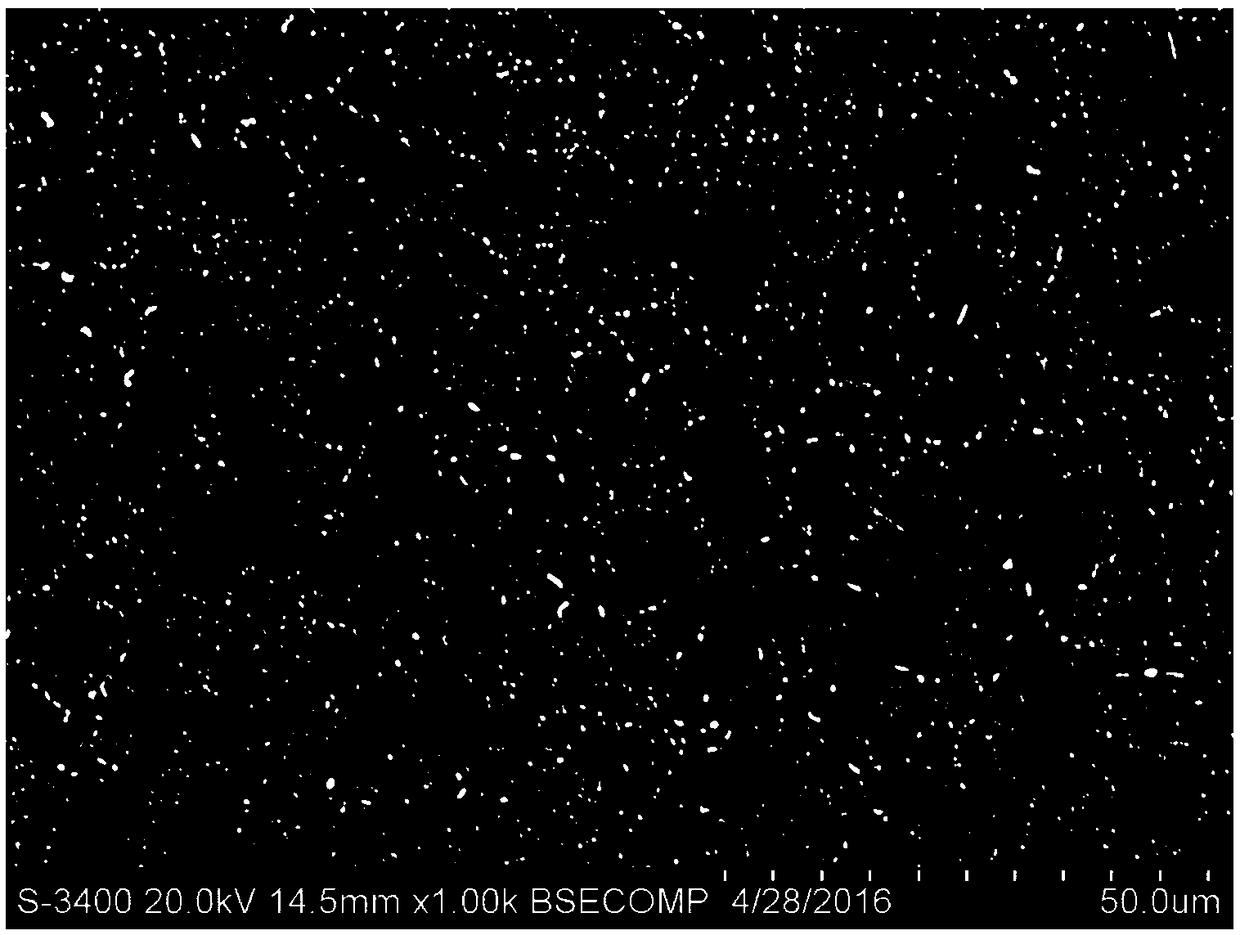

[0053] This embodiment relates to the verification of the carbide content and particle size, heat treatment hardness, and wear resistance of the high-carbon, high-vanadium high-speed steel in Example 1, wherein the carbide content and particle size are analyzed based on the tissue image obtained by scanning electron microscopy, and the heat treatment hardness, wear resistance The performance is tested with reference to GB / T 230.1 and GB / T 12444-2006 respectively.

[0054] The high-carbon high-vanadium high-speed steel of embodiment 1.1,1.2 is compared with the high-carbon high-vanadium high-speed steel (alloy A) of purchase and the high-carbon high-vanadium high-speed steel (alloy B) of the powder metallurgy process, and the results are as follows:

[0055] Table 2.1 Comparison of the composition of Examples 1.1, 1.2 and Alloys A and B

[0056]

[0057] Table 2.2 Carbide content and particle size comparison between Examples 1.1 and 1.2 and alloys A and B

[0058]

[005...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com