Self-lubrication porous elastic oil-containing bearing material and preparation method thereof

A bearing material and self-lubricating technology, applied in the field of bearing materials, can solve the problems of damaged self-lubricating bearing lubrication function, reduced bearing service life, poor critical lubrication state, etc., to ensure overall lubricity, reduce wear, and high oil content. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

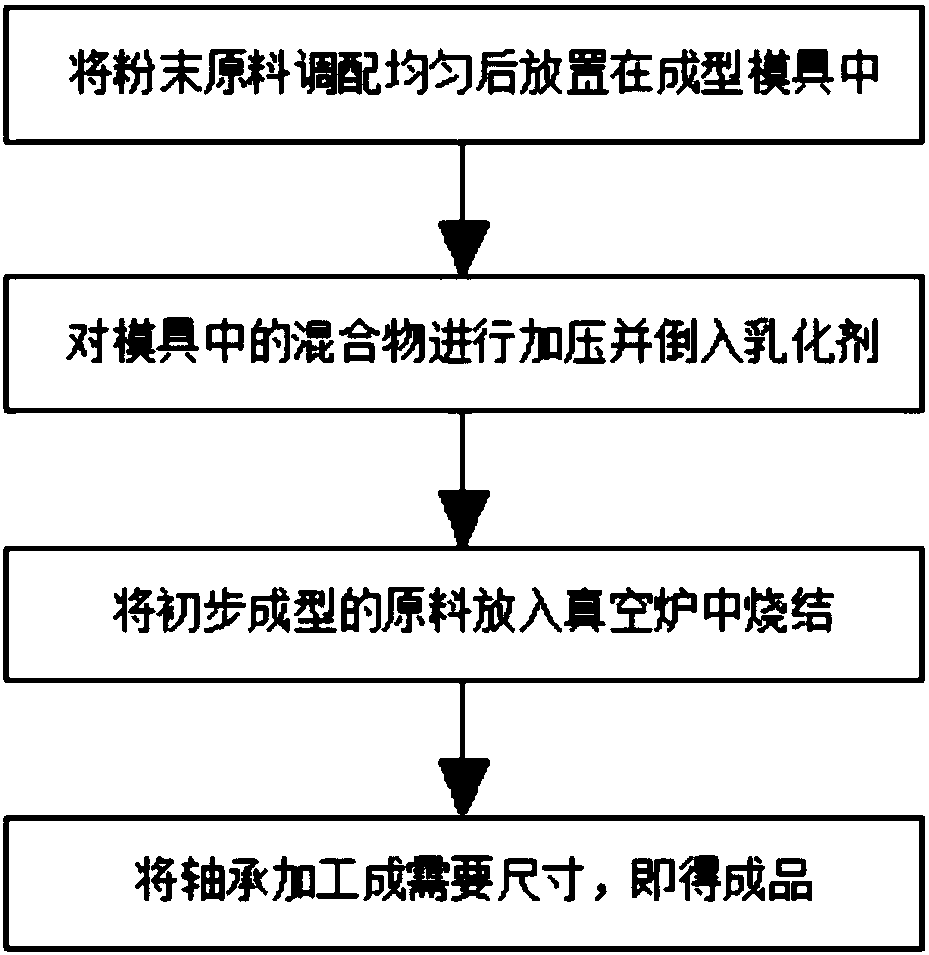

Embodiment 1

[0021] A method for preparing a self-lubricating porous elastic oil-containing bearing material. The specific steps of the method are as follows: S1: After uniformly blending 20 parts of bronze powder, 10 parts of phosphorus alloy powder, 3 parts of chromium carbide powder and 2 parts of solid lubricant, place into the forming mold; S2: pressurize the mixture in the mold to form a porous medium inside, pour 1 part of propylene glycol fatty acid ester on the surface of the mixture, and make it penetrate into the pores inside the mixture, and apply the mixture inside the mold The pressure is 0.5MPa; S3: Put the raw material that is preliminarily formed under pressure into a vacuum furnace for sintering. The sintering temperature in the vacuum furnace is 700°C, the holding time is 10min, and the heating rate is 50°C / min; S4: Sintering is completed Finally, the bearing is processed into the required size to obtain the finished product.

Embodiment 2

[0023] A method for preparing a self-lubricating porous elastic oil-containing bearing material. The specific steps of the method are as follows: S1: After uniformly blending 40 parts of bronze powder, 20 parts of tin alloy powder, 5 parts of chromium carbide powder and 4 parts of solid lubricant, place into the forming mold; S2: pressurize the mixture in the mold to form a porous medium inside, pour 3 parts of sodium stearoyl lactylate on the surface of the mixture, and make it penetrate into the pores inside the mixture, and apply the mixture inside the mold The pressure is 1.5MPa; S3: Put the raw material that is pressurized and initially formed into a vacuum furnace for sintering. The sintering temperature in the vacuum furnace is 900°C, the holding time is 15min, and the heating rate is 50°C / min; S4: Sintering is completed Finally, the bearing is processed into the required size to obtain the finished product.

Embodiment 3

[0025] A method for preparing a self-lubricating porous elastic oil-containing bearing material. The specific steps of the method are as follows: S1: After uniformly blending 30 parts of bronze powder, 15 parts of copper alloy powder, 4 parts of chromium carbide powder and 3 parts of solid lubricant, place Into the forming mold; S2: pressurize the mixture in the mold to form a porous medium inside, pour 2 parts of fatty alcohol oxide ethylene ether on the surface of the mixture, and make it penetrate into the pores inside the mixture. The applied pressure is 1 MPa; S3: Put the raw material that is preliminarily formed under pressure into the vacuum furnace for sintering. The sintering temperature in the vacuum furnace is 800°C, the holding time is 13min, and the heating rate is 50°C / min; S4: The sintering is completed Finally, the bearing is processed into the required size to obtain the finished product.

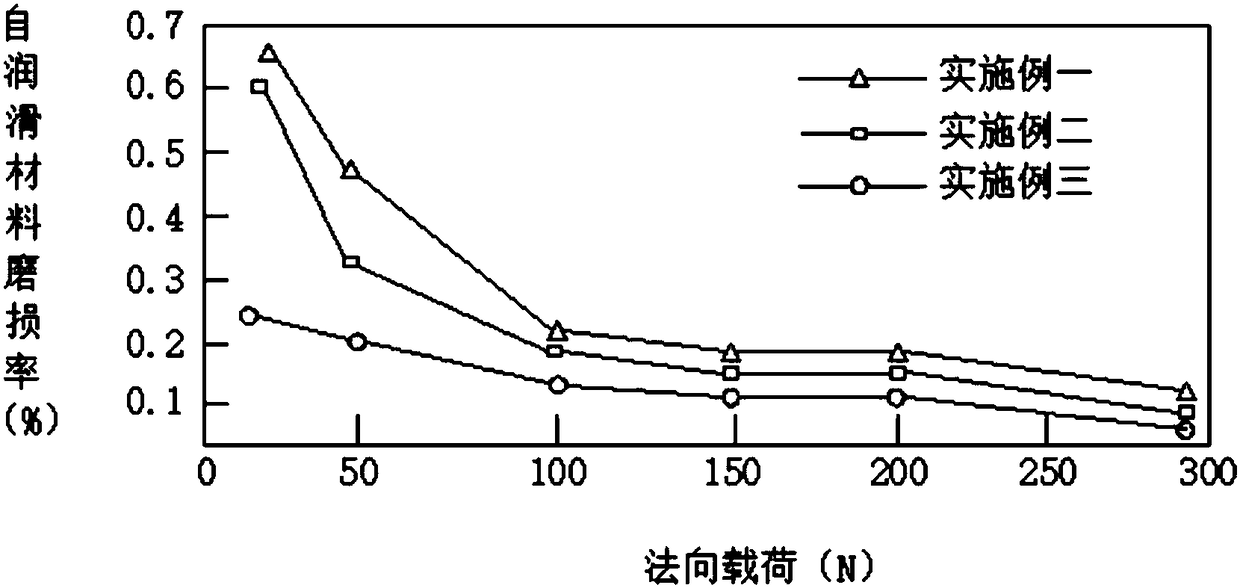

[0026] Aiming at the wear resistance of the self-lubricating porous el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com