Permanent antibacterial, mildew-proof, non-toxic and harmless PP (polypropylene) material and preparation method thereof

A polypropylene material, antibacterial and antifungal technology, applied in the field of materials, can solve the problems of migration of antibacterial agents and difficult to use, and achieve the effect of improving processing performance, excellent lubricating and dispersing agent, and improving smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

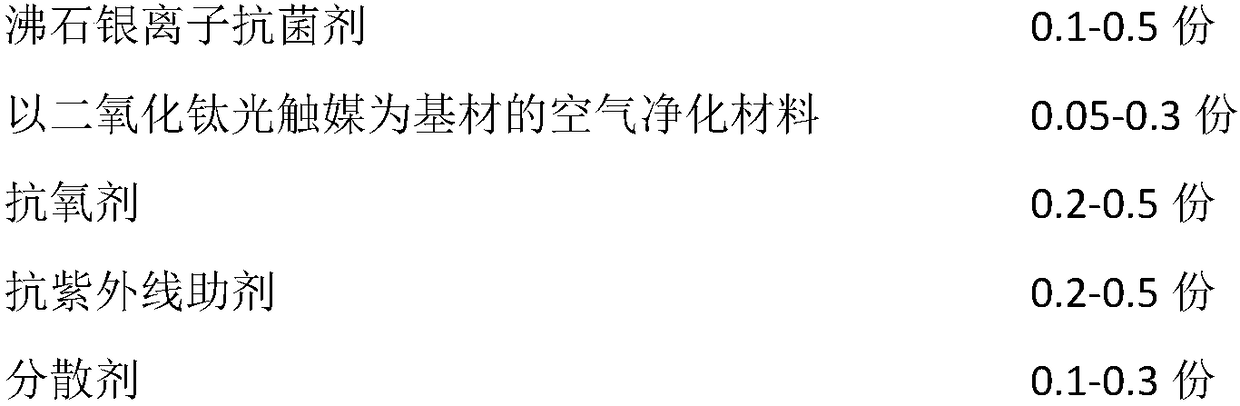

Method used

Image

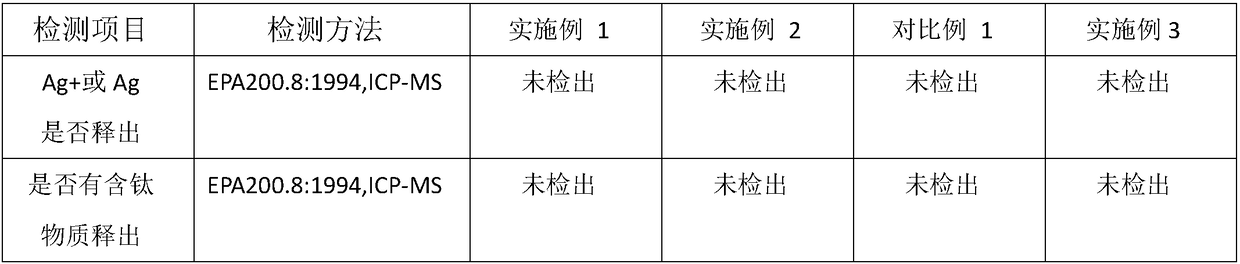

Examples

Embodiment 1

[0036] (1) First dry 0.22 parts of zeolite silver ion antibacterial agent (IM10D-L) and 0.12 parts of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number 201610066352.6) at 90 °C After 2 hours, put the dried two substances into a high-speed mixer, add 0.17 parts by weight of new active siloxane powder, control the temperature at 100° C., and process for 30 minutes to obtain material A.

[0037] (2) Add 98.81 parts of copolymerized polypropylene, 0.4 parts of antioxidant (1010:168:330=0.2:0.1:0.1), 0.3 parts of anti-ultraviolet additive UV-P into the high-speed mixer, blend for 5 minutes, and stir Uniform, get B material.

[0038] (3) Add material B from the main feeding port of the twin-screw extruder, add material A from the side feeding port of the twin-screw extruder, and pass through the temperature of 130-180°C in the twin-screw extruder Melting and kneading, water-cooled strands, air-drying and pellet...

Embodiment 2

[0040] (1) First dry 0.24 parts of zeolite silver ion antibacterial agent (IM10D-L) and 0.15 parts of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number 201610066352.6) at 90 °C After 2 hours, put the dried two substances into a high-speed mixer, add 0.19 parts by weight of new active silicone powder, control the temperature at 100° C., and process for 30 minutes to obtain material A.

[0041] (2) Add 98.72 parts of homopolypropylene, 0.4 parts of antioxidant (1010:168:330=0.2:0.1:0.1), 0.3 parts of anti-ultraviolet additive UV‐P into the high-speed mixer, and blend for 5 minutes. Stir evenly to obtain material B.

[0042] (3) Add material B from the main feeding port of the twin-screw extruder, add material A from the side feeding port of the twin-screw extruder, and pass through the temperature of 130-180°C in the twin-screw extruder Melting and kneading, water-cooled strands, air-drying and pelletizing ...

Embodiment 3

[0044] (1) First dry 0.2 parts of zeolite silver ion antibacterial agent (IM10D-L) and 0.1 part of air purification material based on titanium dioxide photocatalyst (from Chinese invention patent example 1, patent number 201610066352.6) at 90 °C Standby for 2 hours, then put the dried two substances into a high-speed mixer, add 0.16 parts by weight of new active siloxane powder, control the temperature at 100° C., and process for 30 minutes to obtain material A.

[0045] (2) Add 98.84 parts of homopolypropylene, 0.4 parts of antioxidant (1010:168:330=0.2:0.1:0.1), 0.3 parts of anti-ultraviolet additive UV-P into the high-speed mixer, and blend for 5 minutes. Stir evenly to obtain material B.

[0046] (3) Add material B from the main feeding port of the twin-screw extruder, add material A from the side feeding port of the twin-screw extruder, and pass through the temperature of 130-180°C in the twin-screw extruder Melting and kneading, water-cooled strands, air-drying and pell...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com