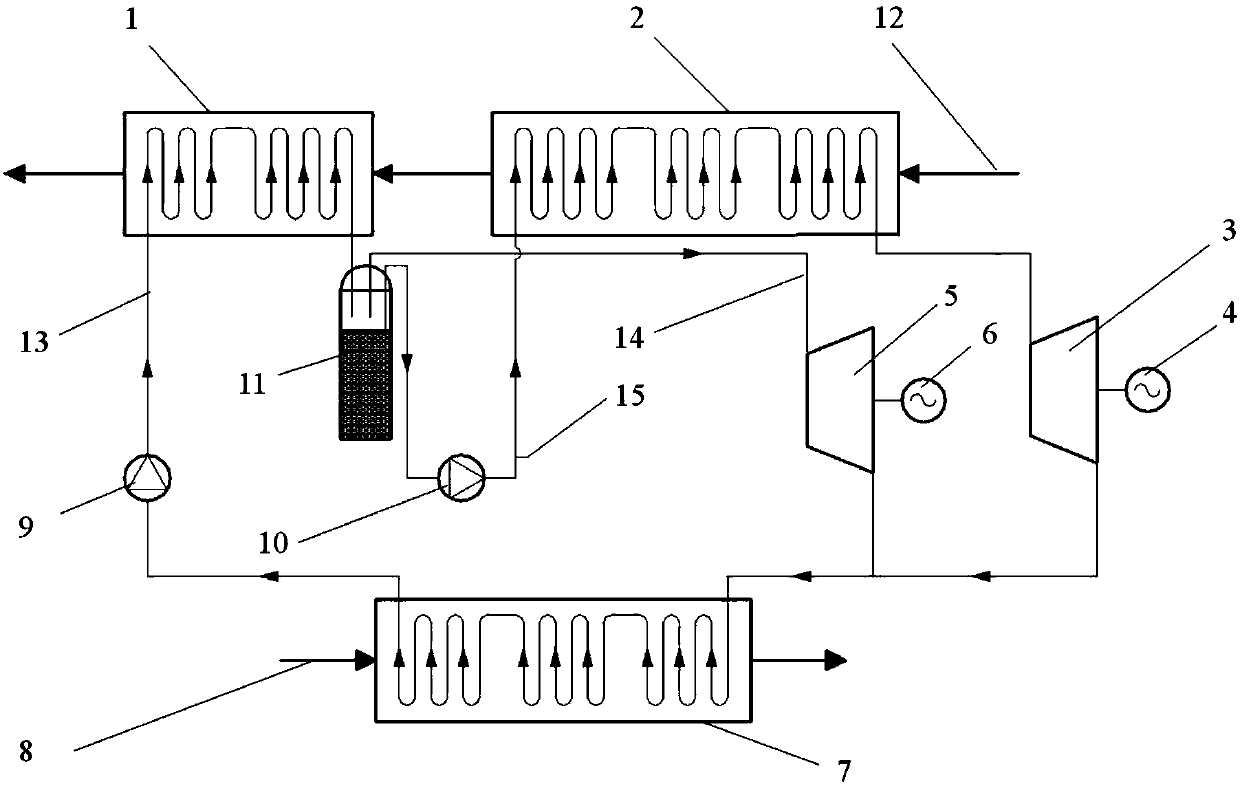

Organic Rankine cycle power generation system based on gas-liquid separation and double-level evaporation

A Rankine cycle and power generation system technology, which is applied in steam engine devices, machines/engines, mechanical equipment, etc., can solve problems such as not being able to meet the system operation, and achieve the effects of maximizing energy utilization, improving practicability, and increasing the temperature range of heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A1

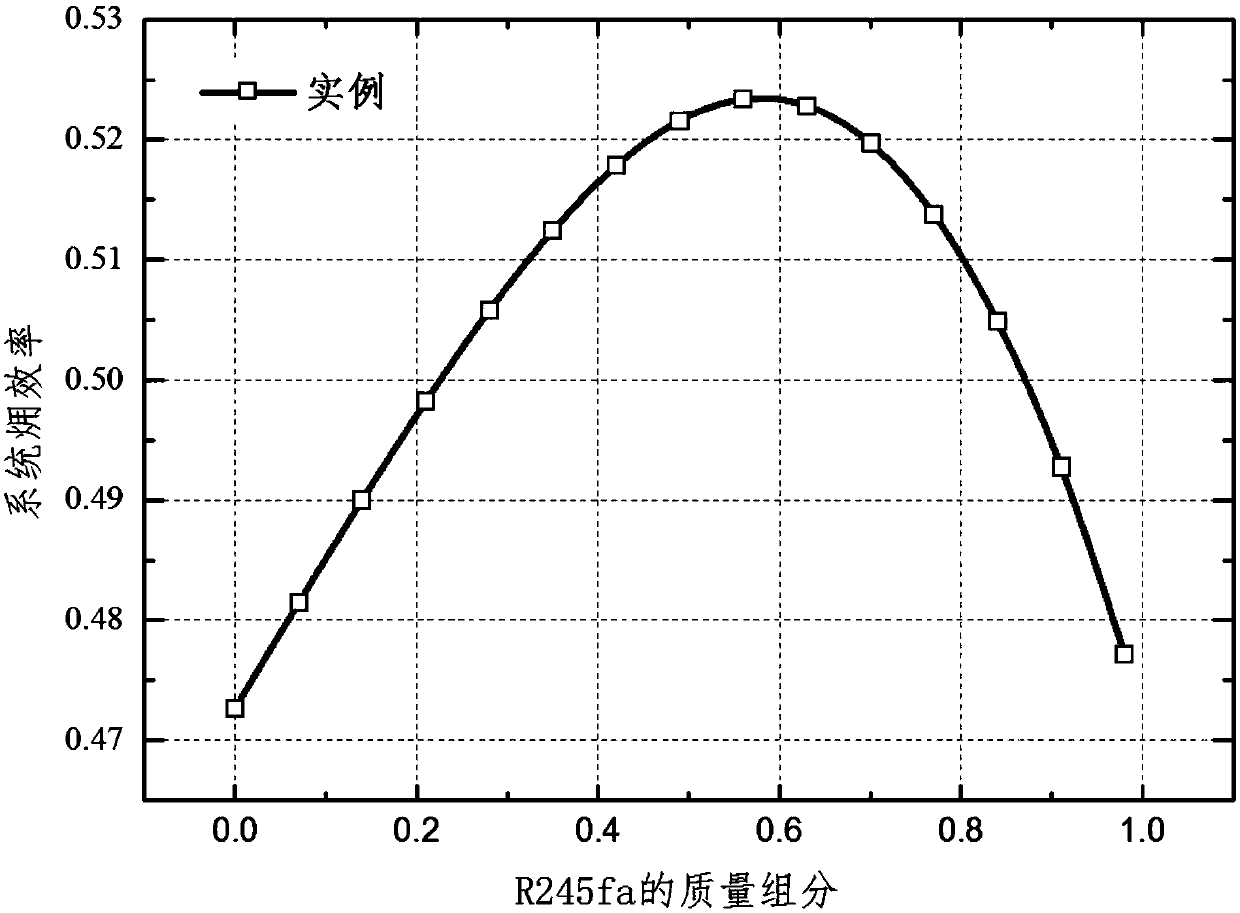

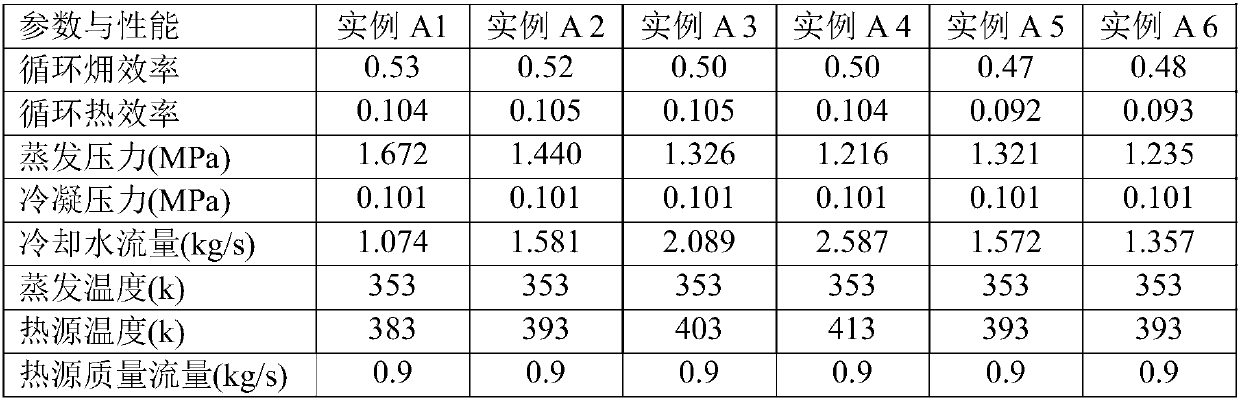

[0030] Example A1: When the temperature of the heat source is 110°C, R245fa / R152a are physically mixed at a ratio of 42:58 and then filled into the system.

Embodiment A2

[0031] Example A2: When the temperature of the heat source is 120°C, R245fa / R152a are physically mixed at a ratio of 56:44 and then filled into the system.

Embodiment A3

[0032] Example A3: When the temperature of the heat source is 130°C, R245fa / R152a is physically mixed at a ratio of 63:37, and then the system is filled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com