A kind of dust removal method and production system for organic silicon and polysilicon production

A production system, organic silicon technology, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, etc., can solve the problems of small particles that cannot be removed, and the service life of dust collectors is short, so as to ensure dust removal performance, reduce energy consumption, The effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

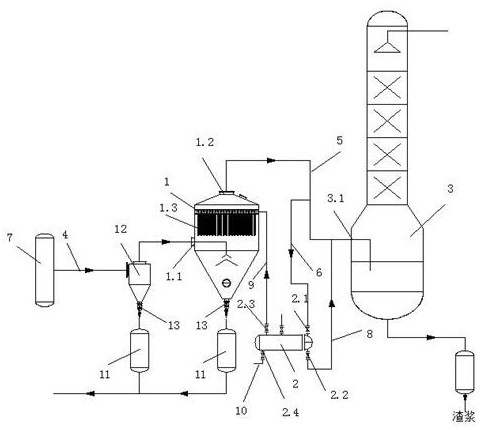

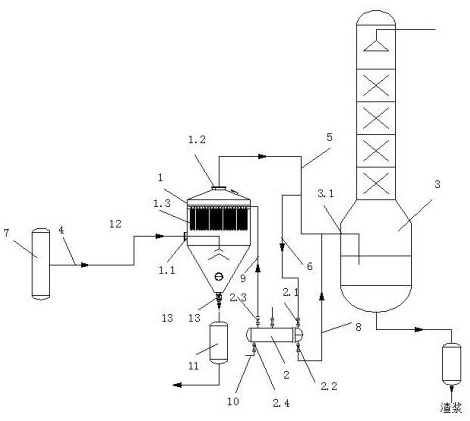

[0018] Embodiment 1: A kind of production system that is used for organic silicon, polysilicon production dedusting method, comprises high temperature too cotton dust collector 1, heat exchanger 2, washing tower 3, waste gas inlet pipe 4 connects high temperature too cotton dust collector 1 flue gas Inlet 1.1, high temperature too cotton dust collector 1 outlet 1.2 is connected to scrubber 3 flue gas inlet 3.1 through outlet pipe 5, and outlet pipe 5 is provided with No. 1 heat exchange inlet pipe 6 connected to heat exchanger 2 No. 1 inlet 2.1, for The No. 1 air outlet 2.2 of the heat exchanger is connected to the air outlet pipe 5 through the No. 1 heat exchange outlet pipe 8, and the No. 2 air outlet 2.3 of the heat exchanger is connected to the back-blowing system of the high-temperature Taimian dust collector 1 through the back-blowing pipe 9, and the No. 2 heat exchanger The gas inlet 2.4 is connected with the methyl chloride gas pipeline 10 . The high temperature Taimia...

Embodiment 2

[0020] Embodiment 2: with reference to embodiment 1, cyclone dust collector 12 can be set before high-temperature too cotton deduster 1, at first with gaseous phase material and solid phase silicon powder and catalyzer discharge from organosilicon or polysilicon fluidized bed reactor synthesis gas First pass through the cyclone dust collector 12 for pretreatment, and then enter the high temperature too cotton dust collector 1 for dry dust removal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com