Denitration catalyst for improving arsenic poisoning resistance as well as preparation method and application of denitration catalyst

A denitrification catalyst and arsenic poisoning technology, applied in environmental protection and catalysts, catalysts in the field of nitrogen oxide purification, can solve problems affecting catalyst activity, selectivity and temperature window, so as to improve anti-arsenic poisoning performance and improve anti-arsenic poisoning performance, low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

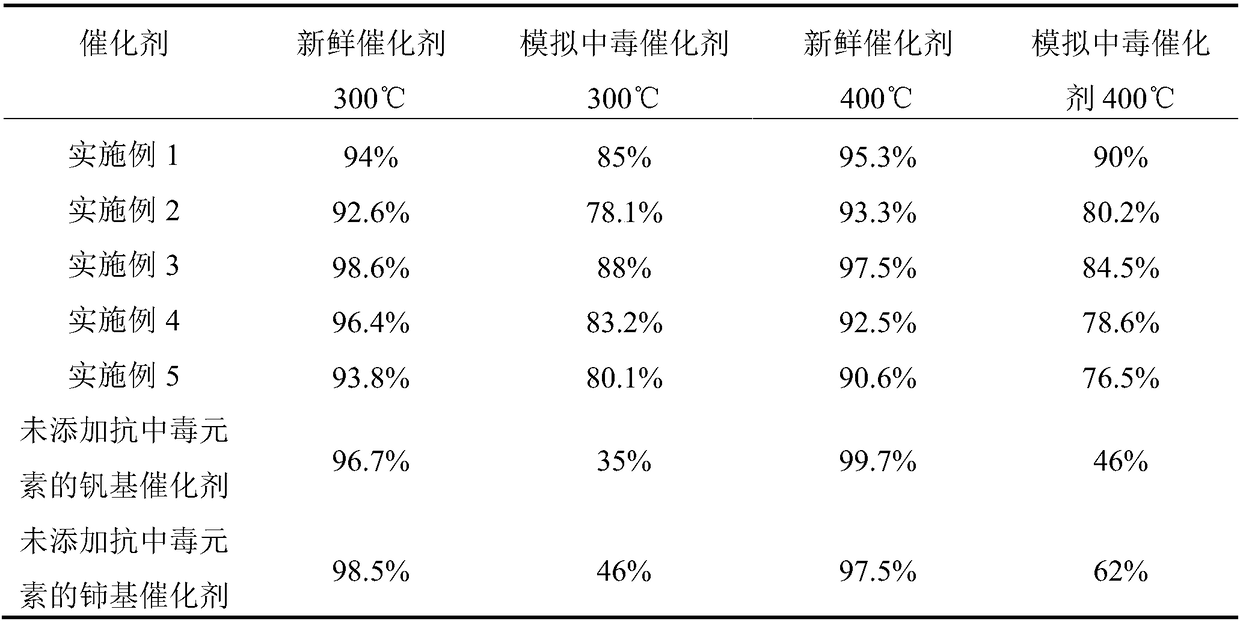

Examples

Embodiment 1

[0021] Example 1 Preparation of VWMgTi catalyst.

[0022] (1) 0.13g of ammonium metavanadate, 0.86g of ammonium metatungstate, 2g of oxalic acid and 1.1g of magnesium nitrate were dissolved in 100mL of deionized water and stirred to obtain a precursor solution;

[0023] (2) Add 9 g of titanium dioxide to the precursor solution in step (1), and stir at room temperature for 120 min to obtain a slurry;

[0024] (3) heating and stirring the slurry at 100° C., gradually evaporating the water in the slurry to obtain a solid;

[0025] (4) The solid substance obtained in step (3) is washed and filtered with deionized water several times, and then dried overnight at 110° C. to obtain a semi-finished product;

[0026] (5) Put the semi-finished product obtained in step (4) into a muffle furnace for roasting. The calcination conditions are as follows: in an air atmosphere, the temperature is raised from room temperature to 500° C. at a rate of 2° C. / min and kept for 4 hours to obtain ...

Embodiment 2

[0027] Example 2 Preparation of VWBaTi catalyst.

[0028] (1) 0.13g of ammonium metavanadate, 0.86g of ammonium metatungstate, 2g of oxalic acid and 0.34g of barium nitrate were dissolved in 100mL of deionized water and stirred to obtain a precursor solution;

[0029] (2) Add 9 g of titanium dioxide to the precursor solution in step (1), and stir at room temperature for 120 min to obtain a slurry;

[0030] (3) heating and stirring the slurry at 100° C., gradually evaporating the moisture in the slurry to obtain a solid;

[0031] (4) The solid material obtained in step (3) is washed and filtered with deionized water several times, and then dried overnight at 110° C. to obtain a semi-finished product;

[0032] (5) Putting the semi-finished product obtained in step (4) into a muffle furnace for roasting to obtain an anti-arsenic poisoning vanadium-tungsten-barium-titanium catalyst.

[0033] The firing conditions are as follows: in air atmosphere, the temperature is raised fr...

Embodiment 3

[0034] Example 3 Preparation of CeWMg catalyst.

[0035] (1) Dissolve 8.68g of cerium nitrate, 7.605g of ammonium tungstate, 2g of oxalic acid and 4.6g of magnesium nitrate in 100mL of deionized aqueous solution and stir to mix;

[0036] (2) Ammonia water with a concentration of 25 wt% was added dropwise to the solution in step (1), controlled at pH=11, and stirred at room temperature for 120 min to fully precipitate;

[0037] (3) Suction filter the precipitate obtained in step (2), and wash it with deionized water several times, and then dry it overnight at 110° C. to obtain a semi-finished product;

[0038] (4) Put the semi-finished product obtained in step (3) into a muffle furnace, and raise it from room temperature to 500°C at a rate of 2°C / min in an air atmosphere and keep it for 4h to prepare an anti-arsenic poisoning cerium-tungsten-magnesium catalyst .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com