Flat plate type SCR catalyst for denitration of arsenic-rich high-ash flue gas and preparation method of flat plate type SCR catalyst

An SCR catalyst, arsenic-rich and high-ash technology, applied in molecular sieve catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of catalyst poisoning, shortened service life, and high cost of catalyst use. The effect of enhancing activity and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

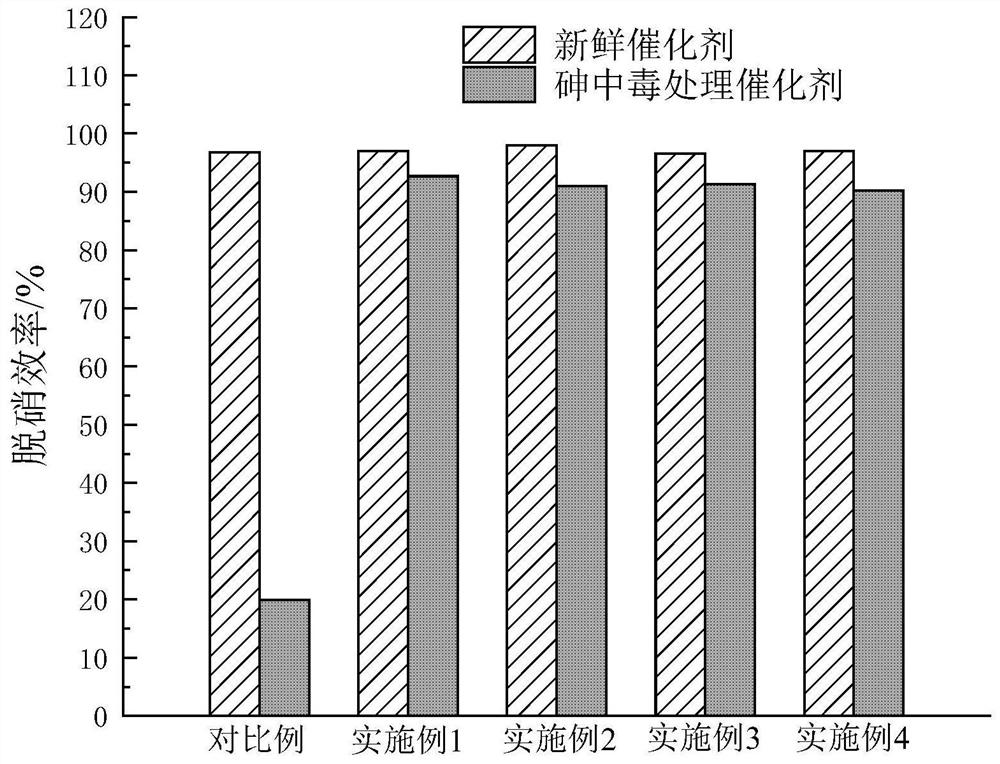

Examples

Embodiment 1

[0024] A method for preparing a flat-plate SCR catalyst for denitrification of arsenic-rich and high-ash flue gas, comprising the following steps:

[0025] Step 1. TiO 2 -Sb 2 o 3 Preparation of -5A molecular sieve mixed carrier

[0026] Dissolve 1327.8g of titanium tetrachloride in 140L of 5°C cold water to obtain a titanium solution, weigh 71.8g of antimony acetate, and dissolve it in ethylene glycol with 3 times the mass to obtain an antimony solution; mix the prepared antimony solution with 14g of polyvinyl butyral Aldehyde and 14g of polyacrylamide were added to the titanium solution together, and the pH value of the solution was adjusted to 6.5 with ethanolamine; the solution was heated to 60°C and kept stirring for 2 hours, after the reaction was completed, it was left to stand for 6 hours, and then filtered to obtain a precipitate; the precipitate was washed with water and dried 、After calcination at 400℃ for 6h, nanotube-shaped TiO 2 -Sb 2 o 3 Solid; add 35g 5A ...

Embodiment 2

[0033] A method for preparing a flat-plate SCR catalyst for denitrification of arsenic-rich and high-ash flue gas, comprising the following steps:

[0034] Step 1. TiO 2 -Sb 2 o 3 Preparation of -5A molecular sieve mixed carrier

[0035] Dissolve 1517.4g of titanium tetrachloride in 80L of 5°C cold water to obtain a titanium solution, weigh 164.1g of antimony acetate, and dissolve it in ethylene glycol twice the mass to obtain an antimony solution; mix the prepared antimony solution with 33g of polyvinyl butyral Aldehyde and 33g of polyacrylamide were added to the titanium solution together, and the pH value of the solution was adjusted to 7.5 with ethanolamine; the solution was heated to 50°C and kept stirring for 4 hours, after the reaction was completed, it was left to stand for 10 hours, and then filtered to obtain a precipitate; the precipitate was washed with water and dried , After calcination at 500℃ for 3h, nanotubular TiO 2 -Sb 2 o 3 Solid; add 80g 5A molecular...

Embodiment 3

[0042] A method for preparing a flat-plate SCR catalyst for denitrification of arsenic-rich and high-ash flue gas, comprising the following steps:

[0043] Step 1. TiO 2 -Sb 2 o 3 Preparation of -5A molecular sieve mixed carrier

[0044] Dissolve 1547.1g of titanium tetrachloride in 90.6L of 5°C cold water to obtain a titanium solution, weigh 92.3g of antimony acetate, and dissolve it with 2.5 times the mass of ethylene glycol to obtain an antimony solution; dilute the prepared antimony solution with 13g of polyvinyl alcohol Butyraldehyde and 13g of polyacrylamide were added to the titanium solution together, and the pH value of the solution was adjusted to 7.2 with ethanolamine; the solution was heated to 55°C and kept stirring for 3h, and stood still for 8h after the reaction, and then filtered to obtain a precipitate; the precipitate was washed with water, Nanotubular TiO was obtained after drying and calcination at 450 °C for 5 h 2 -Sb 2 o 3 Solid; add 52.5g 5A molec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com