Multi-branched Pd-coated PtNi core-shell nano catalyst synthetic method

A technology of nano-catalyst and synthesis method, which is applied in the field of synthesis of multi-branched Pd@PtNi core-shell nano-catalysts, can solve the problems of complex and difficult operation process, and achieve the effect of avoiding cumbersome operation and complicated process and good catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

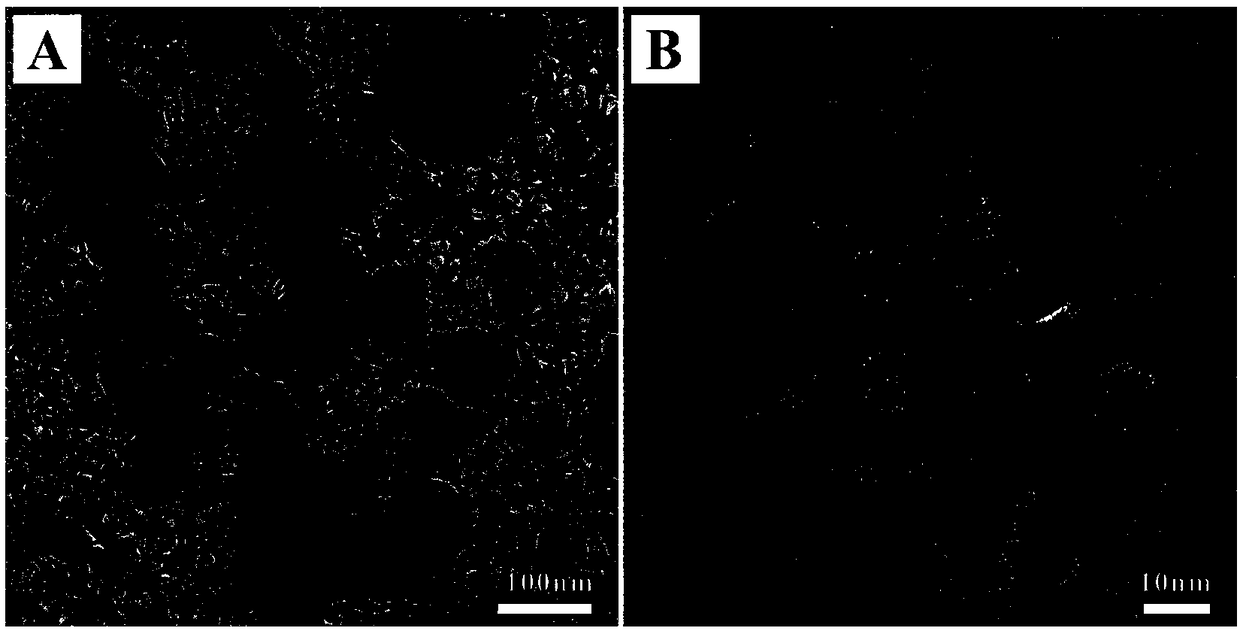

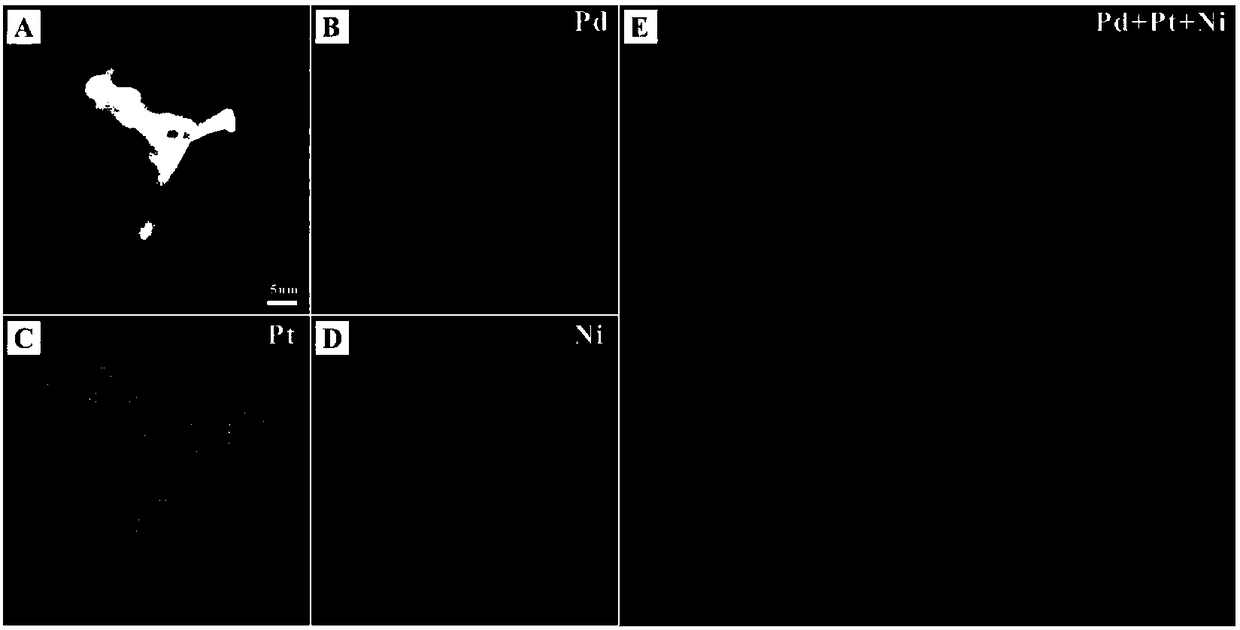

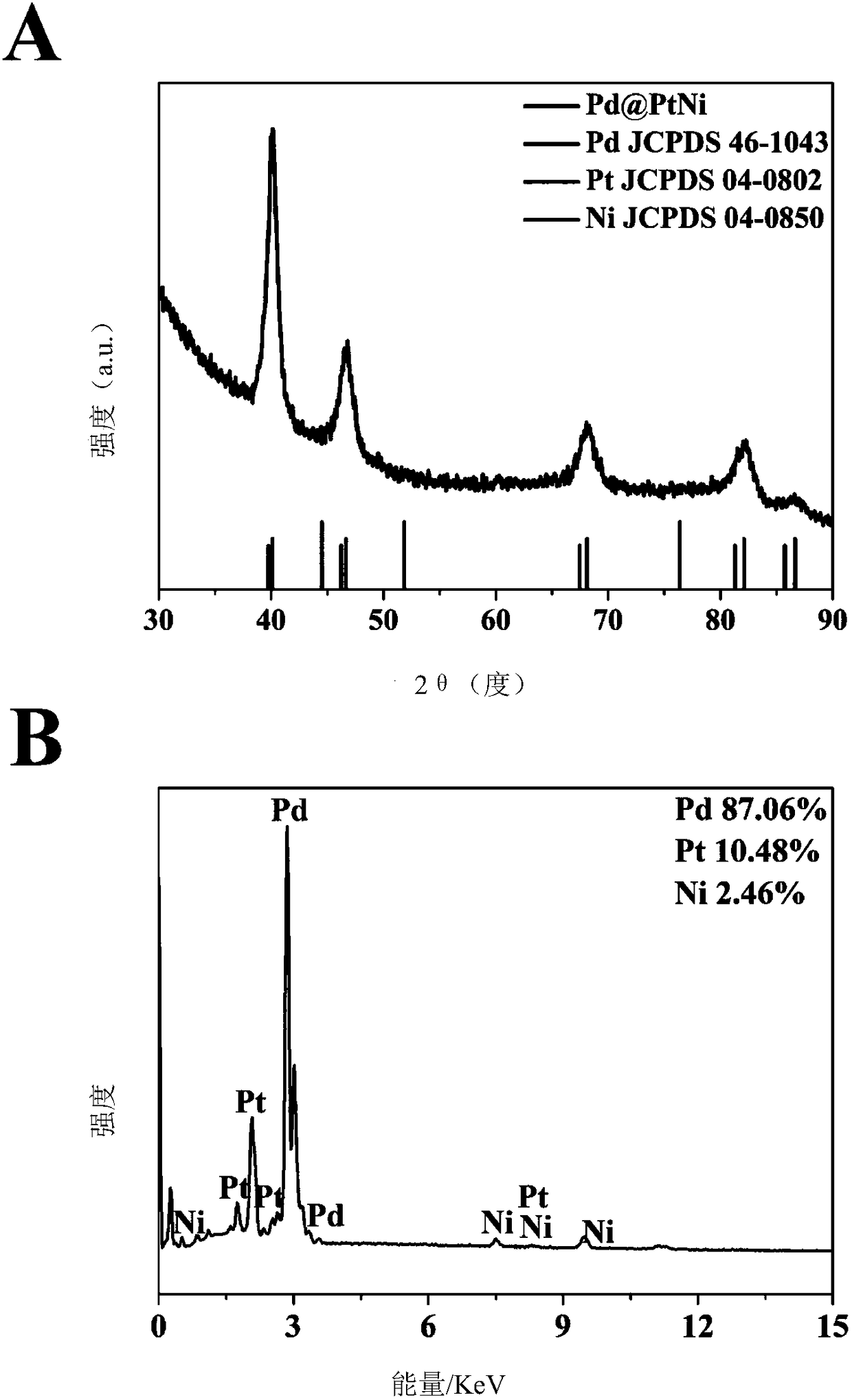

[0028] Please check Figure 1-2 , a method for synthesizing a multi-branched Pd@PtNi core-shell nanocatalyst of the present embodiment, comprising the following steps:

[0029] (1) Dissolution: Add 100mg of cetyltrimethylammonium chloride, 25-100mg of polyvinylpyrrolidone, 8mg of palladium acetylacetonate, and 10mg of platinum acetylacetonate into a 25mL polytetrafluoroethylene reactor liner , 8 mg of anhydrous nickel chloride, 50 mg of tungsten hexacarbonyl, 8 mL of N,N-dimethylformamide, and 4 mL of absolute ethanol.

[0030] (2) Mixing: Stir the solution obtained in step (1) at room temperature at a speed of 600 rpm for 30 min to make it evenly mixed;

[0031] (3) Programmed temperature rise: put the stirred solution in step (2) in an oven, raise the temperature from room temperature to 180°C, and keep it at 180°C for 30 minutes, then rinse with tap water and quickly cool to room temperature;

[0032] (4) Washing: The cooled sample is repeatedly washed with deionized wate...

Embodiment 2

[0035] A method for synthesizing a multi-branched Pd@PtNi core-shell nanocatalyst in this embodiment comprises the following steps:

[0036] (1) Dissolution: Add 100mg of cetyltrimethylammonium chloride, 25-100mg of polyvinylpyrrolidone, 8mg of palladium acetylacetonate, and 10mg of platinum acetylacetonate into a 25mL polytetrafluoroethylene reactor liner , 8 mg of anhydrous nickel chloride, 50 mg of tungsten hexacarbonyl, 10-7 mL of N,N-dimethylformamide, and 2-5 mL of absolute ethanol.

[0037] (2) Mixing: the solution obtained in step (1) was stirred at room temperature at a speed of 600 rpm for 30 min.

[0038] (3) Temperature program: put the stirred solution in step (2) in an oven, raise the temperature from room temperature to 180°C, and keep it at 180°C for 30min, then rinse with tap water and cool.

[0039] (4) Washing: The cooled sample is repeatedly washed with deionized water until the soluble matter is removed, and the obtained precipitate is the product, which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com