A slime water half-condensation flotation process

A coal slime water and process technology, applied in flotation, solid separation, etc., can solve the problems of increased circulating water consumption, impact on re-election, flotation, frequent fluctuations, etc., to increase the probability of contact, eliminate adverse effects, and reduce investment costs Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

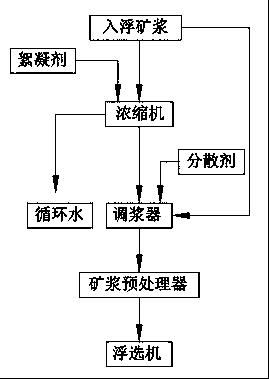

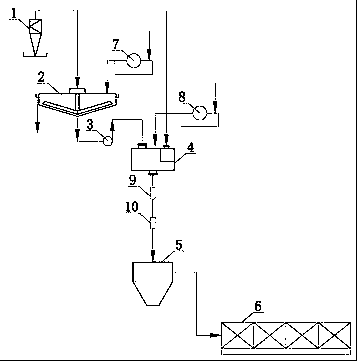

[0026] Attached below figure 1 And attached figure 2 The present invention is further described, but they are not intended to limit the protection scope of the present invention.

[0027] Such as figure 1 As shown, the present invention provides a kind of coal slime water concentrating flotation process, and the design idea of the present invention is: a part of the low-concentration floating ore slurry is first concentrated and processed, and the concentrated high-concentration ore slurry is mixed with another part of the low-concentration ore slurry. Form a suitable and stable concentration of floating pulp. The substantial increase in the concentration of the flotation pulp and the substantial reduction in the flow rate not only reduce the investment cost of the flotation system in the coal preparation plant, but also reduce the production costs such as the consumption of flotation agents, and at the same time help to ensure the stability of the coal slime flotation pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com