A method and device for preparing graphene by chemical vapor deposition from a controllable liquid carbon source

A chemical vapor deposition and graphene technology, applied in chemical instruments and methods, graphene, single-layer graphene, etc., can solve the problems of graphene nucleation and poor thickness uniformity, complex feeding method, poor controllability, etc. Achieve the effect of good uniformity, low production cost and controllable, low defect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The invention provides a method and device for preparing graphene by a controllable liquid carbon source vapor deposition method, comprising the following steps:

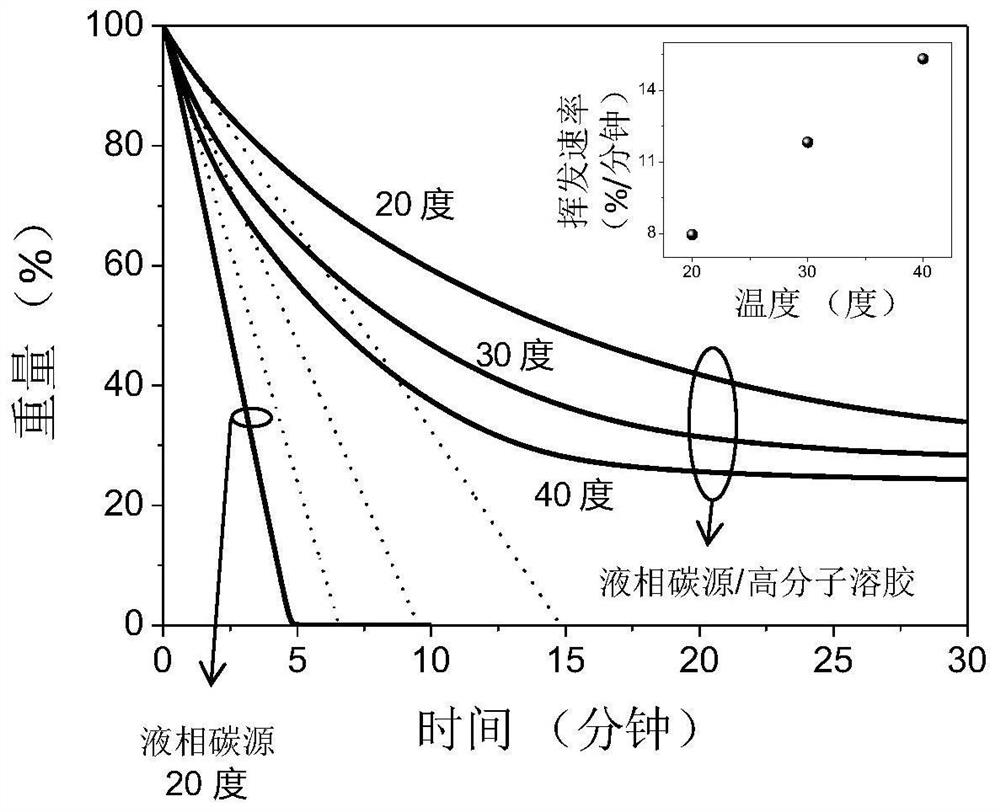

[0040] (1) Dispersing the liquid carbon source in the polymer matrix to form a sol-state carbon source, the liquid carbon source is acetone, the polymer matrix is nitrile-phenolic resin, the mass ratio of the liquid carbon source to the polymer matrix 2:1;

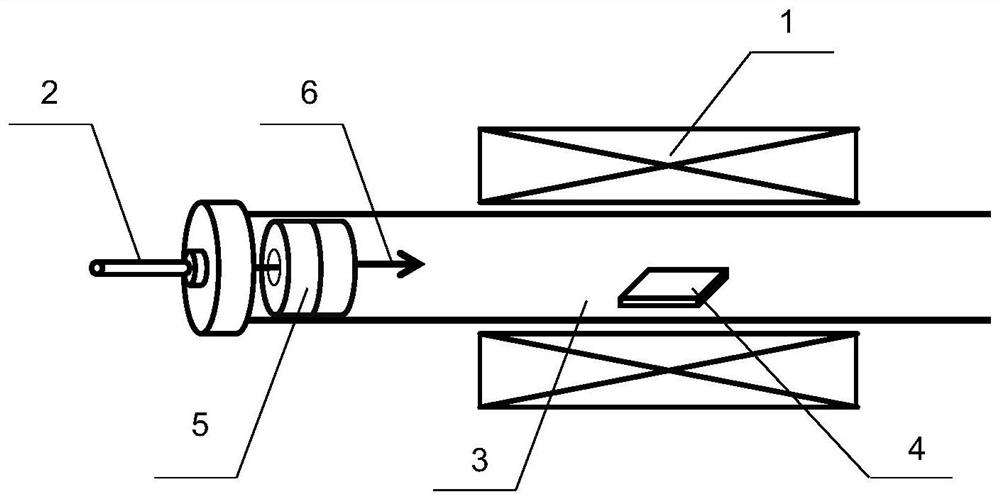

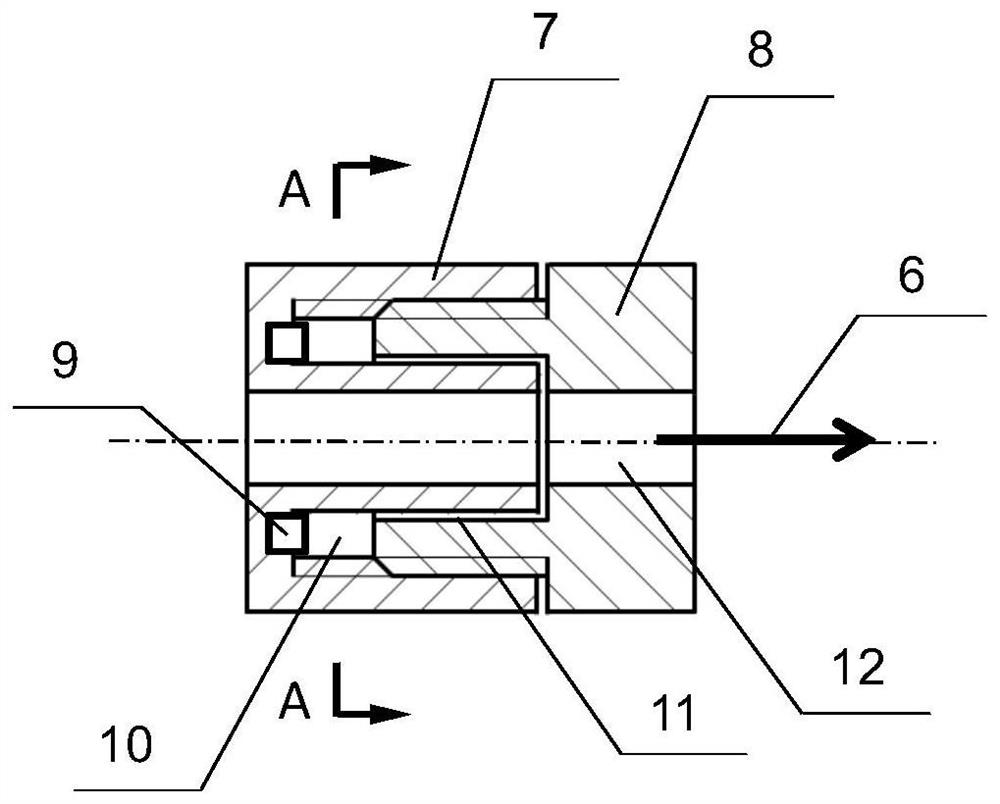

[0041] (2) Place the sol state carbon source in the carbon source feeder, the carbon source feeder is arranged at the inlet end of the chemical vapor deposition reactor, and the catalyst substrate is placed inside the chemical vapor deposition reactor;

[0042] (3) Introduce protective gas and hydrogen into the reactor as carrier gas, raise the central temperature of the reactor to 1040°C, control the internal temperature of the carbon source feeder to be 46°C, and make the carbon source feeder The carbon source steam evaporated from the feeder is mixe...

Embodiment 2

[0046] The invention provides a method and device for preparing graphene by a controllable liquid carbon source vapor deposition method, comprising the following steps:

[0047] (1) Dispersing the liquid carbon source in the polymer matrix to form a sol-state carbon source, the liquid carbon source is acetone, the polymer matrix is nitrile-phenolic resin, the mass ratio of the liquid carbon source to the polymer matrix is 4:1;

[0048] (2) Place the sol state carbon source in the carbon source feeder, the carbon source feeder is arranged at the inlet end of the chemical vapor deposition reactor, and the catalyst substrate is placed inside the chemical vapor deposition reactor;

[0049] (3) Introduce protective gas and hydrogen into the reactor as carrier gas, raise the central temperature of the reactor to 1040°C, control the internal temperature of the carbon source feeder to 50°C, and make the carbon source feeder The carbon source steam evaporated from the feeder is mixe...

Embodiment 3

[0053] The invention provides a method and device for preparing graphene by a controllable liquid carbon source vapor deposition method, comprising the following steps:

[0054] (1) Disperse the liquid carbon source in the polymer matrix to form a sol-state carbon source, the liquid carbon source is acetone / ethyl acetate mixed solution, the polymer matrix is nitrile-phenolic resin, and the liquid carbon source The mass ratio to the polymer matrix is 1:1;

[0055] (2) Place the sol state carbon source in the carbon source feeder, the carbon source feeder is arranged at the inlet end of the chemical vapor deposition reactor, and the catalyst substrate is placed inside the chemical vapor deposition reactor;

[0056] (3) Introduce protective gas and hydrogen into the reactor as carrier gas, raise the central temperature of the reactor to 1030°C, control the internal temperature of the carbon source feeder to 50°C, and make the carbon source feeder The carbon source steam evap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com