Environment-friendly water-permeable brick for sponge city and preparation method of environment-friendly water-permeable brick for sponge city

A sponge city and permeable brick technology, applied in the field of building materials, can solve the problems of weak permeability, no permeable ability, poor permeation effect, etc., to achieve the effect of fast open traffic, superior performance, and increased permeable area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

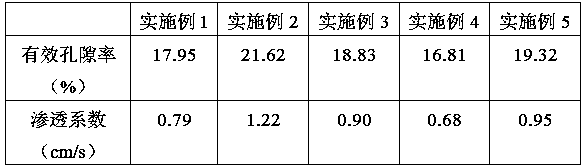

Embodiment 1

[0030] Environmentally-friendly permeable bricks for sponge city, its structure is a two-layer structure connected up and down, the upper layer is the surface layer, and the lower layer is the bottom layer, in parts by weight, the raw materials and dosage of the surface layer are: 350 parts of cement, 1550 parts of silica sand , 3 parts of surface layer admixture, 2 parts of pigment, and 100 parts of water; the raw materials and dosage of the bottom layer are: 1550 parts of sand, 400 parts of cement, 3 parts of bottom layer admixture, and 100 parts of water.

[0031] The surface layer additives are 0.2 parts of water-absorbing resin SAP, 0.8 parts of asphalt powder, 0.5 parts of diffusing agent NNO and 1.5 parts of water reducing agent FDN.

[0032] The bottom layer admixture is 0.2 part of water-absorbing resin SAP, 0.8 part of asphalt powder, 1.5 part of diffusing agent NNO and 0.5 part of water reducer FDN.

[0033] The thickness of the surface layer is 2mm, and the thickne...

Embodiment 2

[0034] Embodiment 2: The environment-friendly water-permeable brick used for sponge city, its structure is the two-layer structure that connects up and down together, and the upper layer is the surface layer, and the lower layer is the bottom layer, by weight, the raw material and consumption of the surface layer are: 400 parts of cement , 1600 parts of silica sand, 5 parts of surface layer admixture, 3.2 parts of pigment, and 100 parts of water; the raw materials and dosage of the bottom layer are: 1600 parts of sand, 500 parts of cement, 5 parts of bottom layer admixture, and 114 parts of water.

[0035] The surface layer additives are 0.3 parts of water-absorbing resin SAP, 2 parts of asphalt powder, 1 part of diffusing agent MF and 1.7 parts of water reducing agent FDN.

[0036] The bottom layer admixture is 0.3 parts of water-absorbing resin SAP, 2 parts of asphalt powder, 1.7 parts of diffusing agent MF and 1 part of water reducer FDN.

[0037] The thickness of the surfa...

Embodiment 3

[0039] Environmentally-friendly permeable bricks for sponge city, its structure is a two-layer structure connected up and down, the upper layer is the surface layer, and the lower layer is the bottom layer, in parts by weight, the raw materials and dosage of the surface layer are: 450 parts of cement, 1650 parts of silica sand , 8 parts of surface layer admixture, 20 parts of pigment, and 150 parts of water; the raw materials and dosage of the bottom layer are: 1650 parts of sand, 600 parts of cement, 8 parts of bottom layer admixture, and 150 parts of water.

[0040] The surface layer additives are 0.5 parts of water-absorbing resin SAP, 3.5 parts of asphalt powder, 1 part of diffusing agent NNO and 3 parts of water reducing agent FDN.

[0041] The bottom layer admixture is 0.5 parts of water-absorbing resin SAP, 3.5 parts of asphalt powder, 3 parts of diffusing agent NNO and 1 part of water reducing agent FDN.

[0042] The thickness of the surface layer is 8mm, and the thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com