Rectification and purification method of abamectin

A technology of abamectin and purification method, applied in chemical instruments and methods, preparation of sugar derivatives, sugar derivatives, etc., can solve problems such as large steam consumption, high energy consumption, long concentration time, etc., and meet production cycle requirements. effect used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

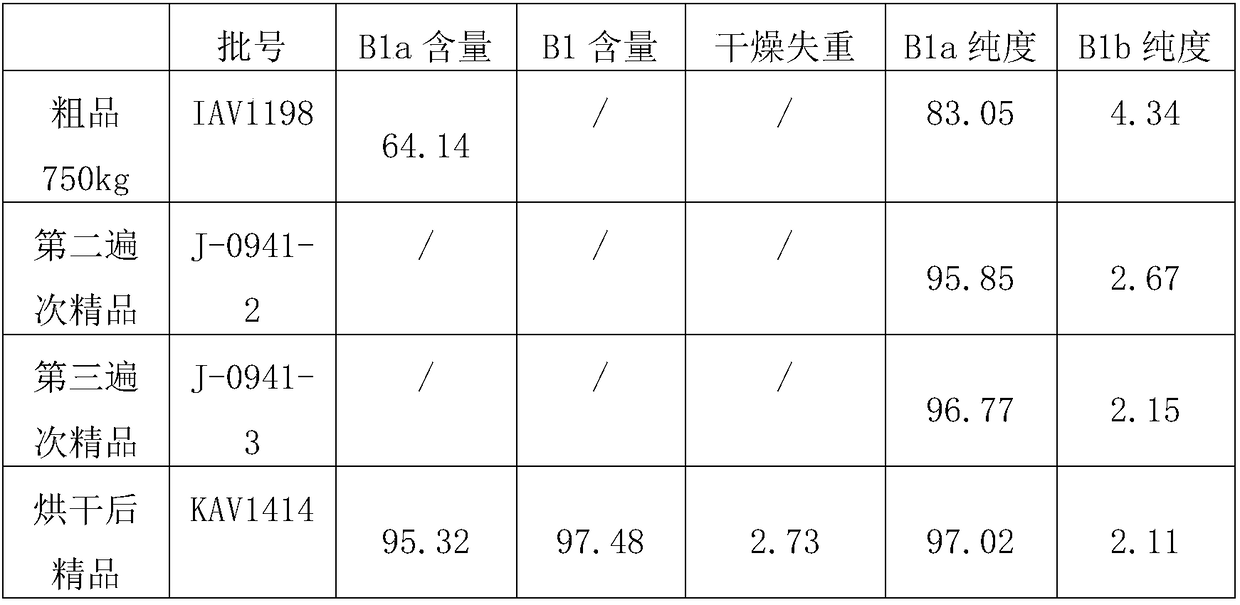

Embodiment 1

[0030] A method for refining and purifying abamectin, the refining and purifying of the first batch of abamectin is carried out according to the existing conventional method, and the refining and purifying of each batch is carried out in the form of applying mechanically the mother liquor afterwards, comprising steps as follows:

[0031] (1) During the refining and purification of the second batch of avermectins, add the second methanol mother liquor in the first batch of avermectin refining and purification to the crude product of avermectin, and the addition amount of the second batch of methanol mother liquor is avermectin 6.9 times of the weight of the crude product of mycin, then heat up to 70°C for insulation, filter after all the abamectin is dissolved, cool down to 25°C for crystallization of the filtered crystallization solution, and then press filter for 4 hours to carry out the first pass of refining to obtain For the first pass of refined products, the mother liquor...

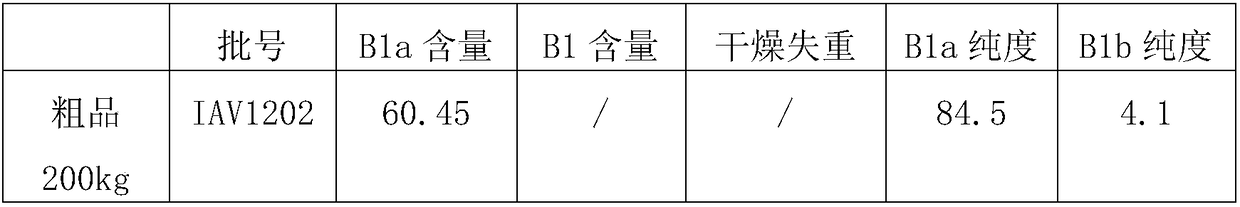

Embodiment 2

[0038] A kind of refining purification method of Abamectin, with embodiment 1, difference is:

[0039] Step (1) The amount of methanol mother liquor added twice is 7.1 times the weight of the crude product of abamectin, and then the temperature is raised to 72°C for insulation, and the avermectin is completely dissolved and then filtered, and the filtered crystal solution is cooled to 27°C Carry out crystallization, then press filter 6h to carry out the first round of refining,

[0040] Step (2) adds three times of methanol mother liquor in the first batch of abamectin refining and purification to the first batch of fine products and heats up to keep 72°C for insulation, and the addition amount of three times of methanol mother liquor is the weight of abamectin crude product 8.3 times of 8.3 times, after the first time the refined product is dissolved, the temperature is lowered to 27°C for crystallization;

[0041] Step (3) adds new methanol to the second time fine product a...

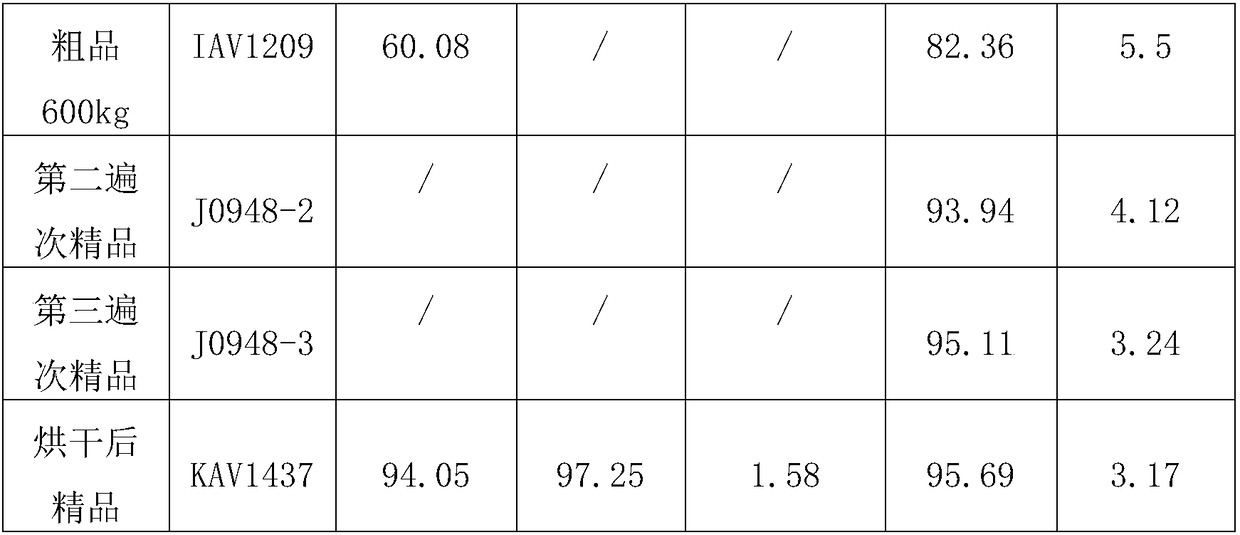

Embodiment 3

[0045] A kind of refining purification method of Abamectin, with embodiment 1, difference is:

[0046] Step (1) The amount of methanol mother liquor added twice is 7.5 times the weight of the crude product of abamectin, and then the temperature is raised to 75°C for insulation, and the avermectin is completely dissolved and then filtered, and the filtered crystal solution is cooled to 30°C Carry out crystallization, then press filter 4h to carry out the first round of refining,

[0047] Step (2) adds three times of methanol mother liquor in the first batch of abamectin refining and purification to the first batch of fine products and heats up to keep 75°C for insulation, and the addition amount of three times of methanol mother liquor is the weight of abamectin crude product 8.5 times of 8.5 times, the first time after the refined product is dissolved, the temperature is lowered to 30°C for crystallization;

[0048] Step (3) adds new methanol to the second time fine product a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com