High-strength magnesium alloy capable of quickly reacting with media and preparation method thereof

A fast-response, high-strength technology, applied in the field of metal materials, can solve problems such as narrow controllable range, low reaction rate between magnesium alloys and media, and inability to meet industrial applications, to improve tensile strength and yield strength, controllable range wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

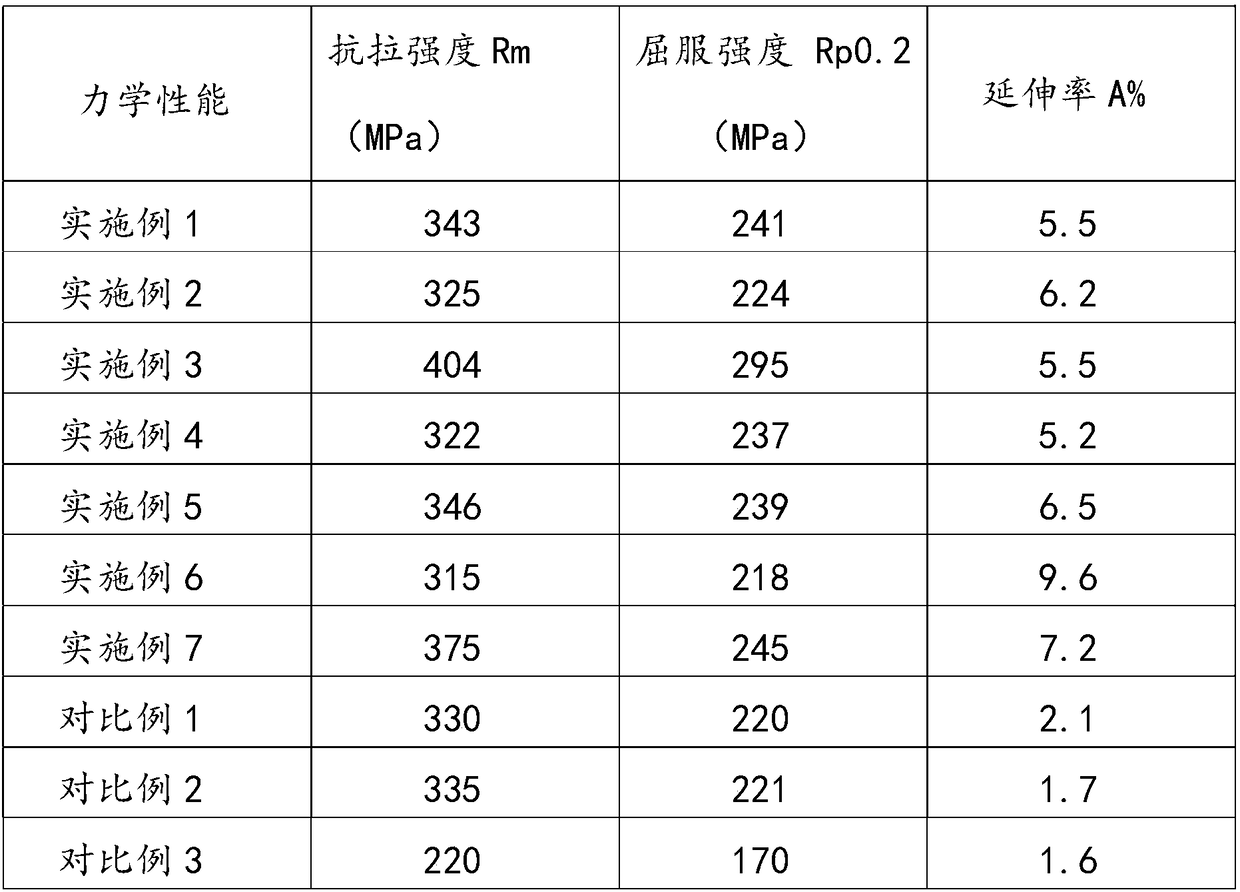

Examples

preparation example Construction

[0027] The preparation method of the high-strength magnesium alloy reacting rapidly with the medium of the present invention comprises steps:

[0028] Weigh raw materials such as magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, magnesium-zirconium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy, nickel, gallium, indium and other raw materials, of which magnesium, magnesium-gadolinium master alloy, magnesium Yttrium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy and nickel are preheated at 100-300°C for 5-10h;

[0029] The raw materials are mixed, then smelted in a crucible resistance furnace, covered by adding a covering agent, and refined by refining agent 1 or 2, so that the ingredients are evenly mixed, inclusions are removed, and cast at 670-750°C to obtain an ingot;

[0030] Perform homogenization heat treatment on the ingot at 450-540°C, and the treatment time is...

Embodiment 1

[0040] 5.0 parts of gadolinium, 2.0 parts of yttrium, 1.0 parts of aluminum, 4.0 parts of zinc, 0.3 parts of zirconium, 1.3 parts of rhenium, 1.0 parts of silicon, copper, iron, nickel, gallium and indium in total, and 0.1 parts of beryllium and calcium , Magnesium 90 parts.

[0041] The preparation method is as follows:

[0042] Weigh raw materials such as magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, magnesium-zirconium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy, nickel, gallium, indium and other raw materials, of which magnesium, magnesium-gadolinium master alloy, magnesium Yttrium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy and nickel are preheated at 100°C for 5 hours;

[0043] The raw materials are mixed, then smelted in a crucible resistance furnace, covered with a covering agent, and refined with a refining agent 1, so that the ingredients are evenl...

Embodiment 2

[0048] 1.0 parts of gadolinium, 3.0 parts of yttrium, 0.6 parts of aluminum, 6.5 parts of zinc, 0.1 parts of zirconium, 2.0 parts of rhenium, the total amount of silicon, copper, iron, nickel, gallium, and indium is 0.05 parts, and the content of beryllium and calcium is 0.2 parts , 83 parts of magnesium.

[0049] Weigh raw materials such as magnesium, magnesium-gadolinium master alloy, magnesium-yttrium master alloy, magnesium-zirconium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy, nickel, gallium, indium and other raw materials, of which magnesium, magnesium-gadolinium master alloy, magnesium Yttrium master alloy, aluminum, zinc, aluminum-silicon master alloy, aluminum-iron master alloy and nickel are preheated at 300°C for 10 hours;

[0050] The raw materials are mixed, then smelted in a crucible resistance furnace, covered with a covering agent, and refined with a refining agent 2, so that the ingredients are evenly mixed, inclusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com