Hard alloy and preparation method and application

A cemented carbide and wire rolling technology, which is applied in the field of cemented carbide, can solve the problems of adhesive wear, stainless steel work hardening, and low service life of roller rings, so as to improve the anti-adhesive wear performance, good anti-adhesive wear performance, Inhibit the effect of continuing to grow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

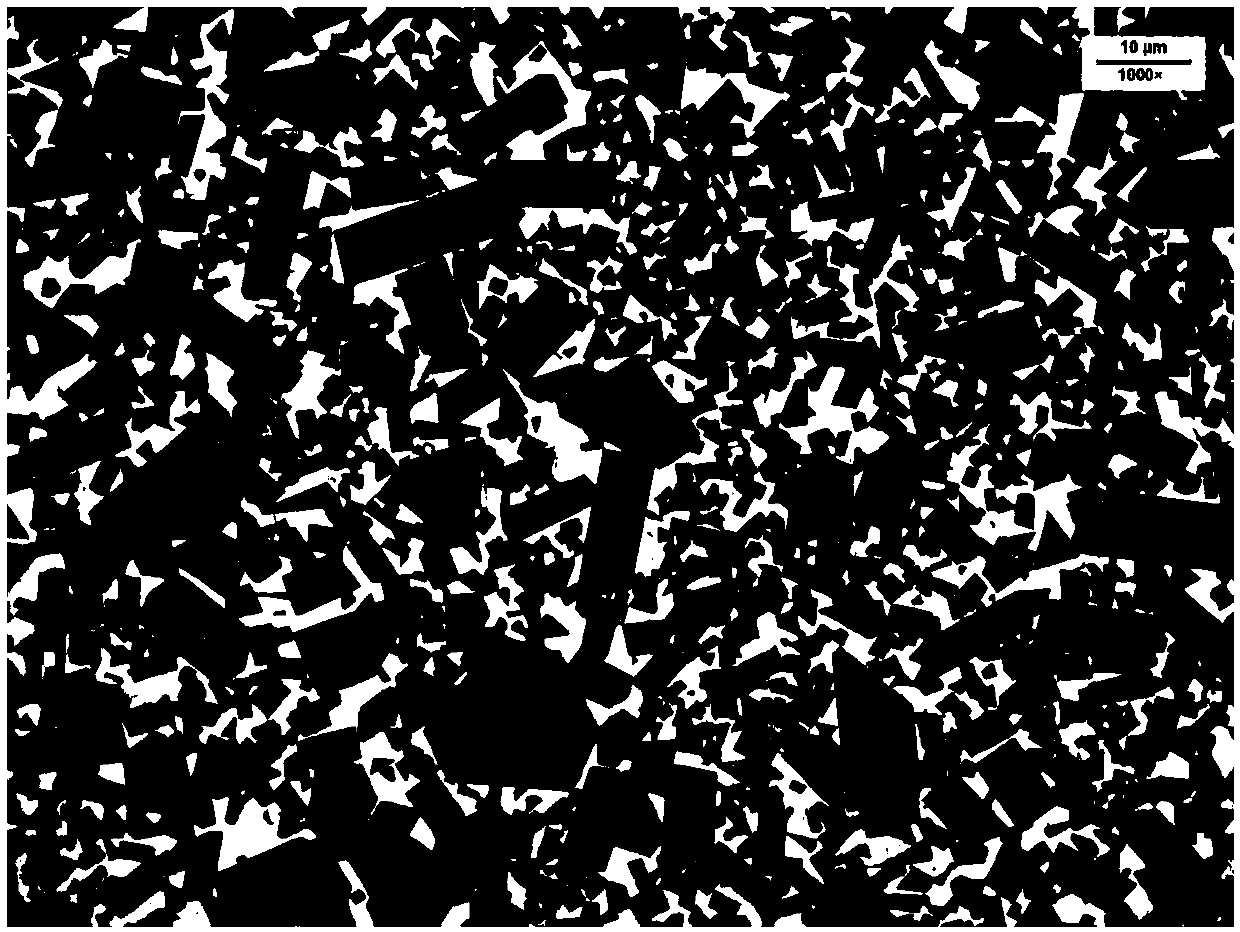

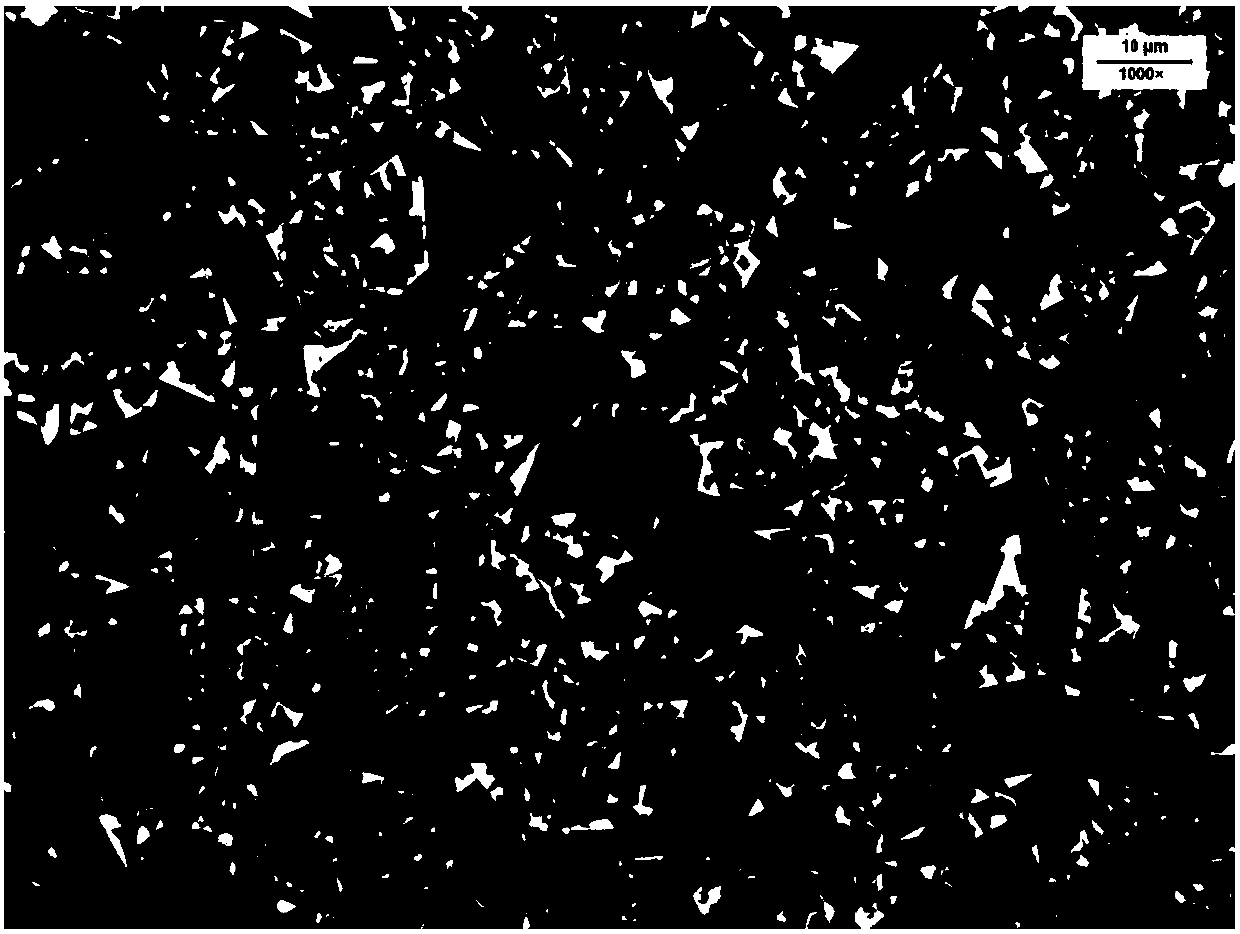

[0040] Using 30% by weight of flaky crystal tungsten carbide with a grain size of 10.0μm (where the area of the unit cell along the {0001} crystal plane is The ratio of the area of crystal plane growth is 5, denoted as S{0001} / S 0.8% Cr 3 C 2 Powder, 6% Co powder and the balance of ordinary WC powder with a particle size of 4μm as raw materials; according to the requirements for the final preparation of WC-Co-Cr cemented carbide bulk materials, the above raw materials are mixed in proportion and wet milled for 20h , The uniformly refined mixed powder is spray-dried to prepare the mixed material; then the mixed powder is cold pressed into a compact, placed in a sintering furnace for liquid phase sintering at a sintering temperature of 1500°C, and then cooled to room temperature in the sintering furnace.

Embodiment 2-5

[0042] Examples 2-5 are the same as Example 1, except that the content of Co powder is changed. The specific parameters are shown in Table 1.

Embodiment 6-10

[0044] Example 6-10 is the same as Example 1, only changing Cr 3 C 2 The powder content and specific parameters are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com