Ternary boride ceramic coating with palygorskite and preparation method thereof

A ternary boride and ceramic coating technology, which is applied in the coating, metal material coating process, fusion spraying, etc., can solve the problems of density and wear resistance limitations, and achieve good friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

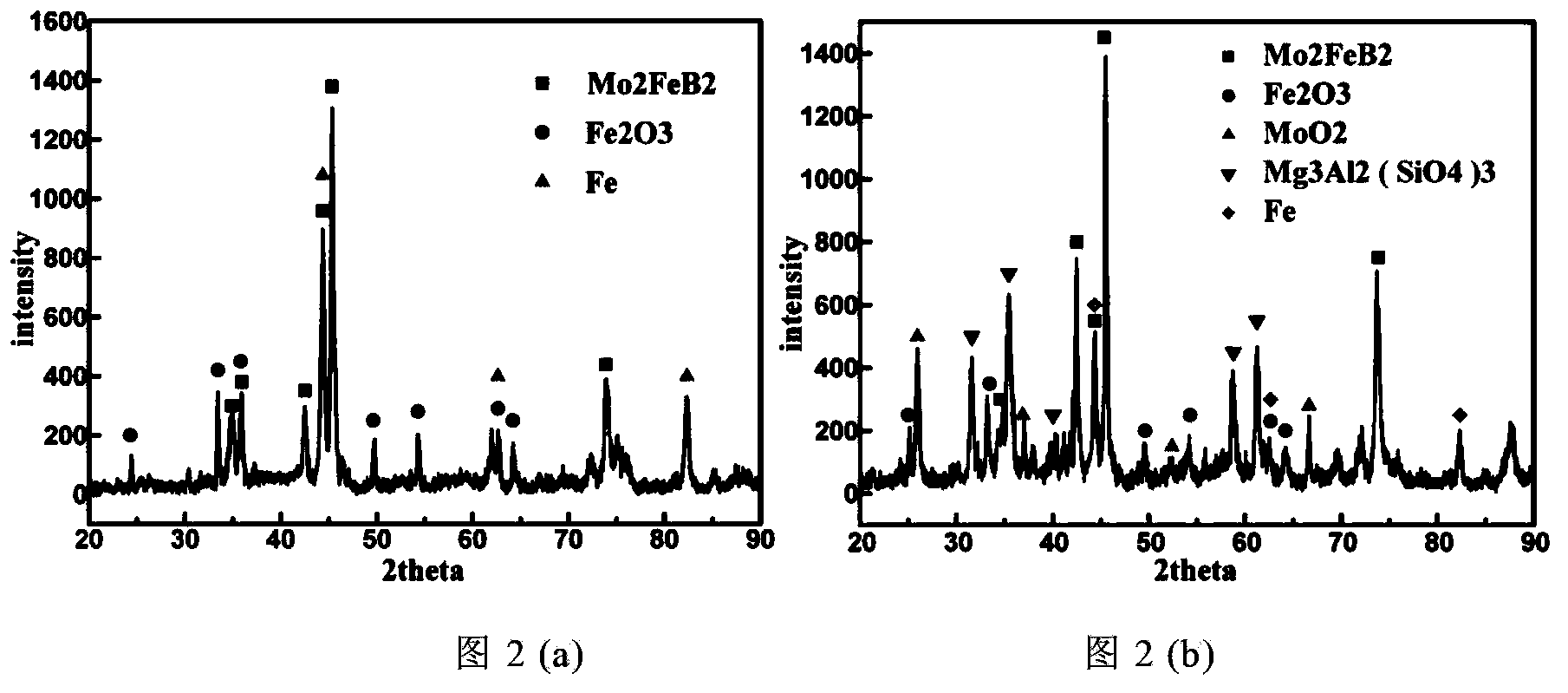

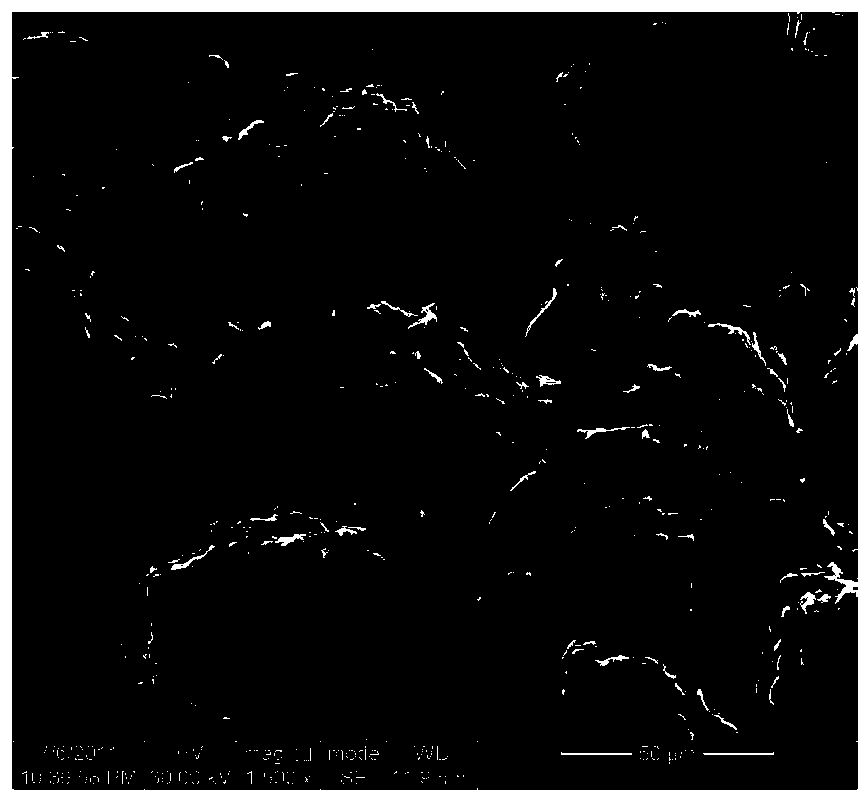

[0038] The invention provides a ternary boride ceramic coating and a preparation method thereof. The ternary boride ceramic coating is prepared on a transition layer on a substrate, and the ternary boride ceramic coating contains Mg 3 Al 2 (SiO 4 ) 3 and MoO 2phase, there are square block crystals and rectangular strip crystals in the coating, and the square crystals and rectangular strip crystals are uniformly dispersed in the binder phase. The square block crystal is mainly the target phase of spraying——Mo 2 FeB 2 Cemented carbide phase, rectangular strip crystals containing Mo 2 FeB 2 Cemented carbide phase, and contains magnesium aluminum silicate - Mg 3 Al 2 (SiO 4 ) 3 . The porosity of the coating is 10.71%-15.66%, which is lower than that of the coating without palygorskite. The bonding strength of the coating is between 16.68 and 17.48 MPa, which is increased relative to the bonding strength of the coating before adding palygorskite. The microhardness valu...

Embodiment 1

[0077] The preparation method provided by the present invention is adopted to prepare a ternary boride ceramic coating, and the mass fraction of palygorskite is 2%, and the specific preparation method is as follows:

[0078] The first step, raw material preparation:

[0079] The matrix material is selected as ordinary Q235-A steel, and the aggregates are sprayed: Mo powder, micron carbonyl Fe powder, and FeB alloy powder are selected as the sprayed aggregate components. The average particle size of the Mo powder is 44.74 μm, and the bulk density is 7.15. g / cm 3 , The purity of molybdenum powder is greater than 99.95%. The average particle size of micron carbonyl Fe is 4.95μm, and the bulk density is 2.66g / cm 3 , the purity is greater than 99.5%. The average particle size of FeB alloy powder is 6.47μm, and the bulk density is 5.29g / cm 3 . The raw material of the transition layer is nickel-clad aluminum powder in Ni-Al alloy powder.

[0080] The second step is the preparat...

Embodiment 2

[0091] The first step, raw material preparation:

[0092] The base material is ordinary Q235-A steel. Mo powder, micron carbonyl Fe powder, and FeB alloy powder are selected as spray aggregate components. The average particle size of the Mo powder is 43 μm, and the bulk density is 6.5 g / cm 3 , The purity of molybdenum powder is greater than 99.95%. The average particle size of micron carbonyl Fe is 4μm, and the bulk density is 2g / cm 3 , the purity is greater than 99.5%. The average particle size of FeB alloy powder is 6μm, and the bulk density is 5g / cm 3 . The nickel-clad aluminum powder in the Ni-Al alloy powder is selected to spray the transition layer on the substrate.

[0093] The second step to the fourth step are the same as in Example 1, and the mass percentage of palygorskite added during the preparation of the spray powder is 1%.

[0094] The fifth step is preheating, the preheating temperature is 400°C, and the preheating time is 7 minutes.

[0095] The sprayi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com