Multiband sample irradiation device based on atomic force microscope

An atomic force microscope and irradiation device technology, applied in the field of electrical, magnetic, material surface morphology and mechanical, thermal performance testing, can solve the problem that the relevant performance cannot be guaranteed to not change again, the analysis accuracy is limited, and the surface performance index cannot be changed. Real-time analysis and other issues to achieve the effect of power density adjustment, power adjustment, and interference avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

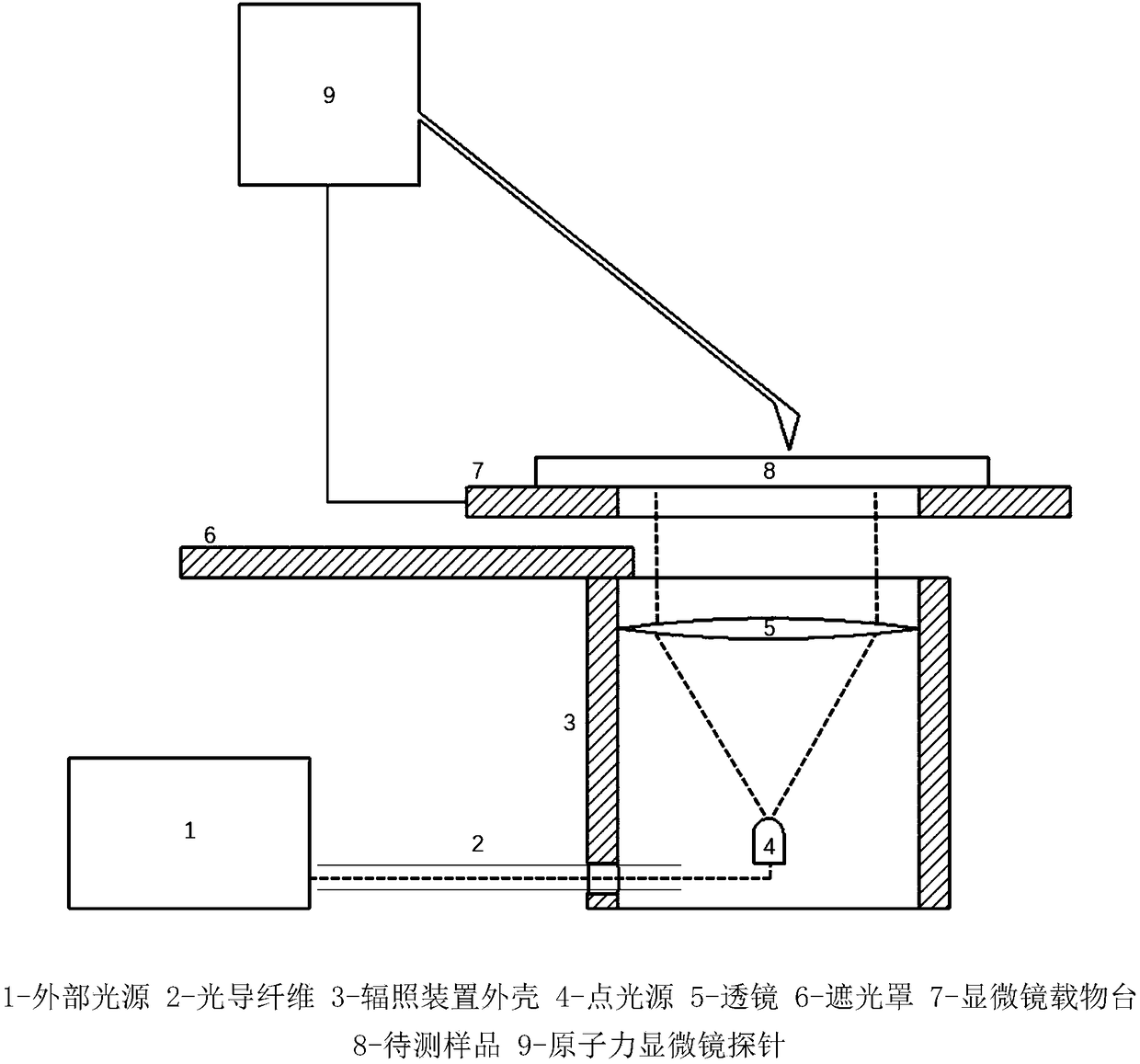

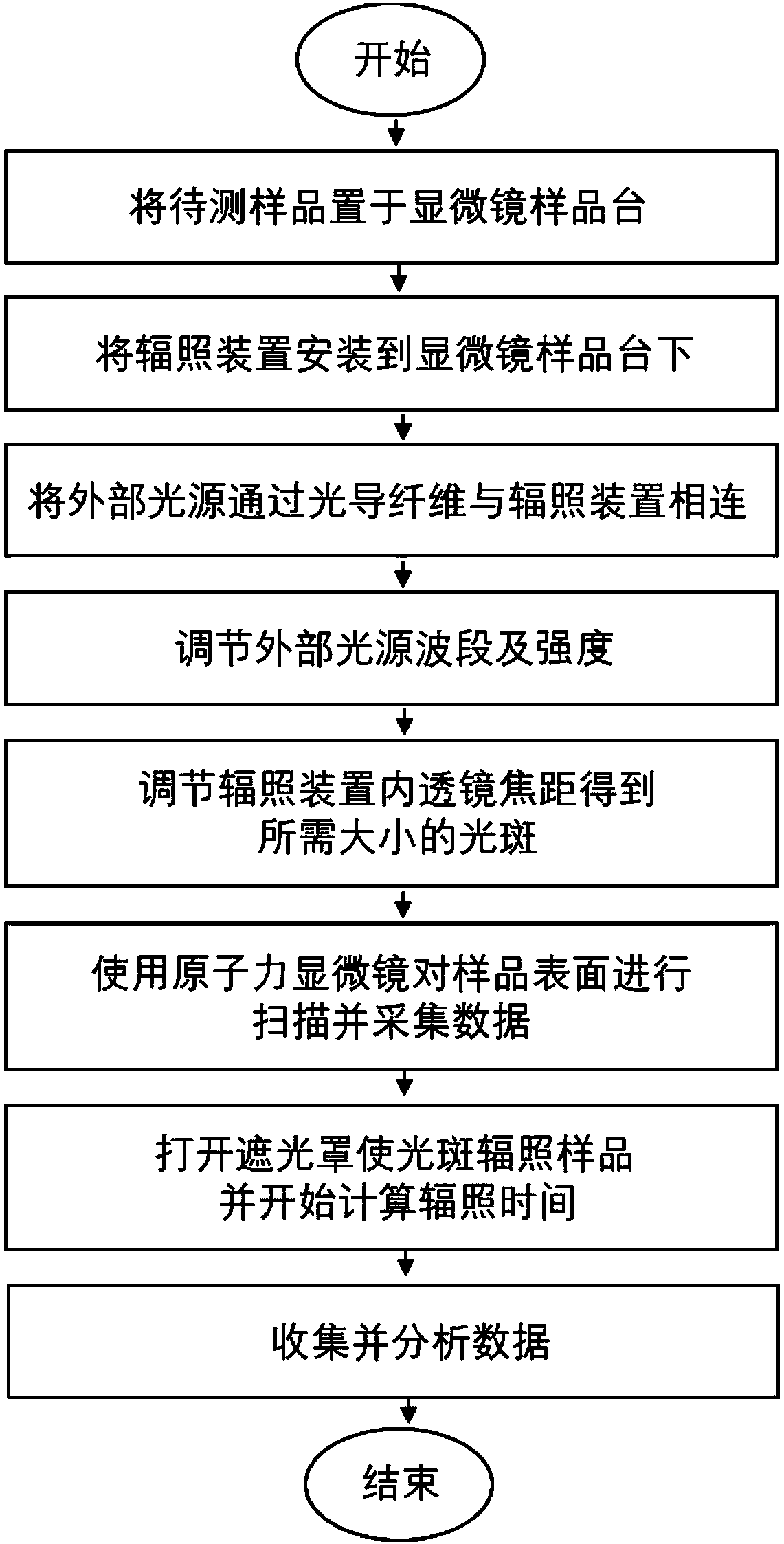

[0028] In embodiment 1, the method for measuring the surface morphology and modulus of elasticity of polylactic acid film under 355nm ultraviolet band irradiation for 5 minutes, the flow process is as follows figure 2 As shown, it specifically includes the following steps:

[0029] (1) if figure 1 As shown, the light irradiation device 3 is connected with the atomic force microscope 9 as shown in the figure, and a 2×2 cm polylactic acid film 8 is fixed on the microscope stage 7 . The external light source 1 emits 355nm ultraviolet light, which is transmitted to the light-emitting head 4 through the optical fiber 2, and the beam spreads upward in a point-like manner, and is restrained by the lens 5 to form parallel light;

[0030] (2) Set the atomic force microscope to the contact mode, use a conventional probe to continuously scan the polylactic acid film, and open the light shield 6 to start the experiment until irradiated for 5 minutes. Through software synthesis and anal...

Embodiment 2

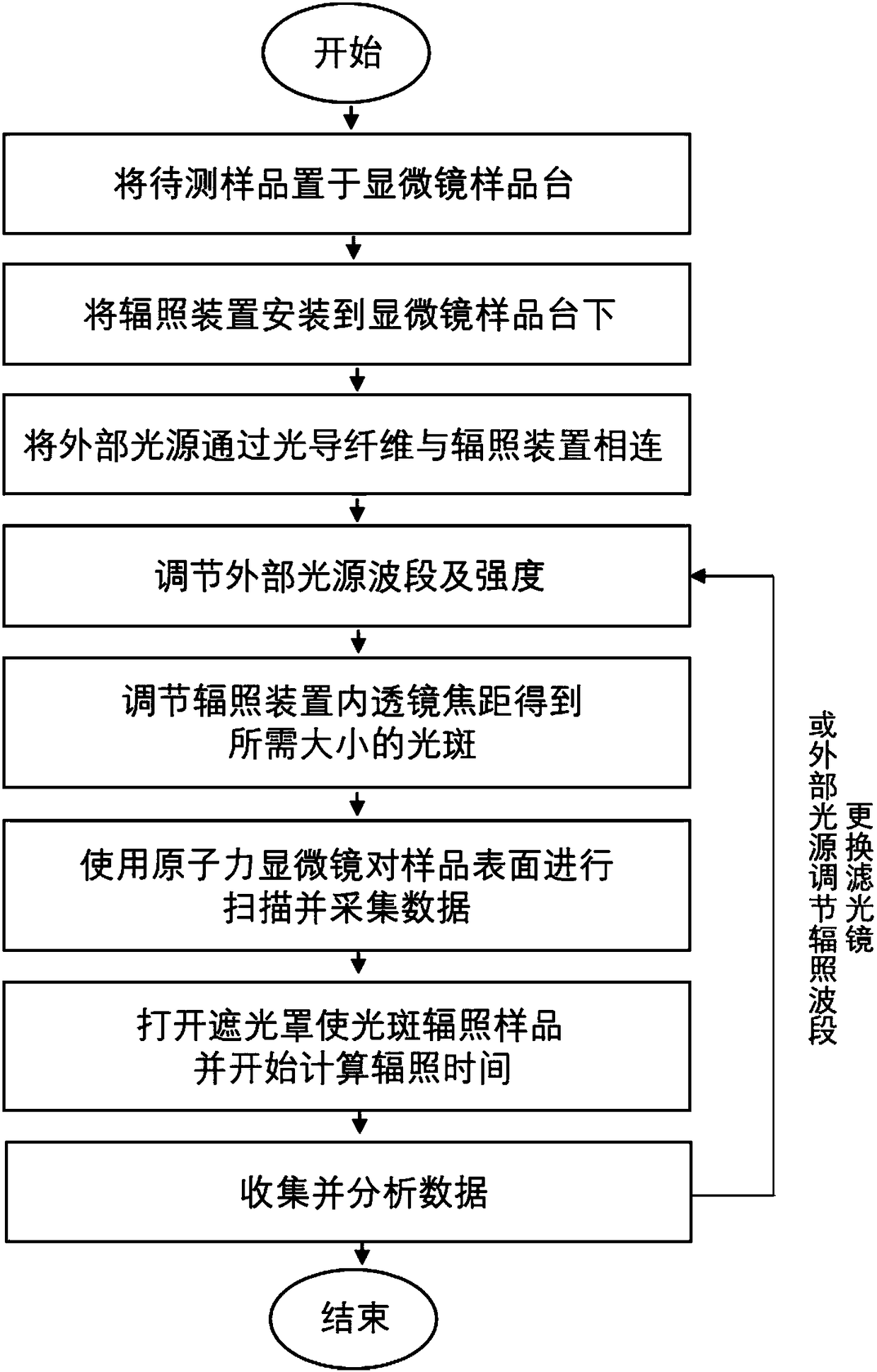

[0033] In embodiment 2, the method for measuring the surface morphology and modulus of elasticity of polylactic acid film under 488nm, 546nm, 800nm band irradiation for 5 minutes, the flow process is as follows image 3 As shown, it specifically includes the following steps:

[0034] (1) if figure 1 As shown in the figure, the light irradiation device was connected with the atomic force microscope as shown in the figure, and a 2×2cm polylactic acid film (referred to as group A1) was fixed on the microscope stage. Connect the visible light external light source and adjust the filter to emit 488nm visible light, which is transmitted to the light-emitting head through the optical fiber, and the beam spreads upward in a point-like manner, and is restrained by the lens to become parallel light;

[0035] (2) Set the atomic force microscope to the contact mode, and use a conventional probe to scan the polylactic acid film continuously until it is irradiated for 5 minutes. After s...

Embodiment 3

[0042] In embodiment 3, the method for measuring the real-time changes in surface morphology, electrical resistance and thermal resistance of a single crystal silicon thin film under 488nm band irradiation for 5 minutes, the process is as follows Figure 4 As shown, it specifically includes the following steps:

[0043] (1) if figure 1 As shown in the figure, the light irradiation device was connected with the atomic force microscope as shown in the figure, and a 2×2 cm single crystal silicon film (recorded as group B1) was fixed on the microscope stage. Connect the visible light external light source and adjust the filter to emit 488nm visible light, which is transmitted to the light-emitting head through the optical fiber, and the beam spreads upward in a point-like manner, and is restrained by the lens to become parallel light;

[0044](2) Set the atomic force microscope to the contact mode, and use a conventional probe to scan the single crystal silicon film continuously ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com