Environment-friendly geothermal floor capable of improving indoor air quality

A technology for indoor air quality and geothermal floor, applied in the direction of floor covering, modified epoxy resin adhesive, chitin polysaccharide coating, etc., can solve problems such as poor formaldehyde content processing ability, and achieve the effect of ensuring freshness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

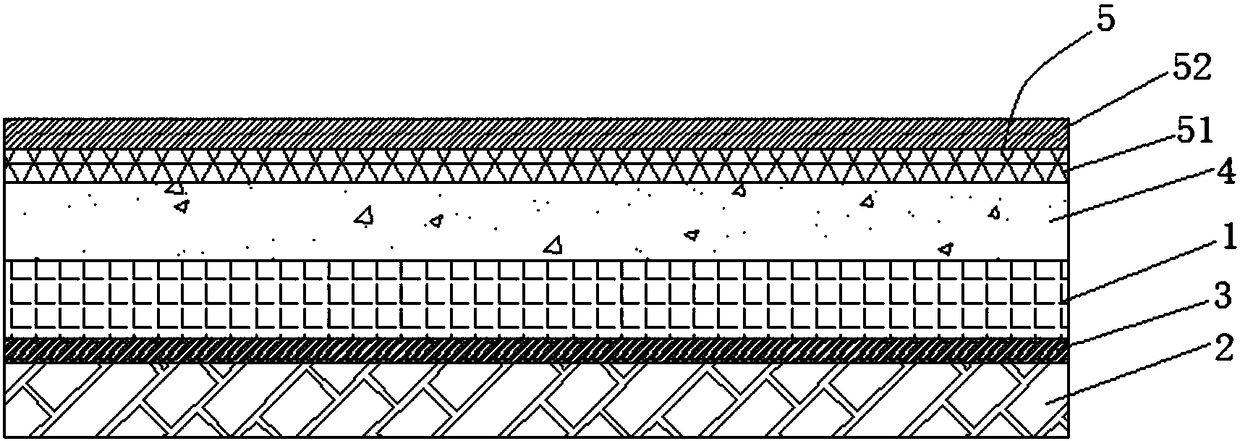

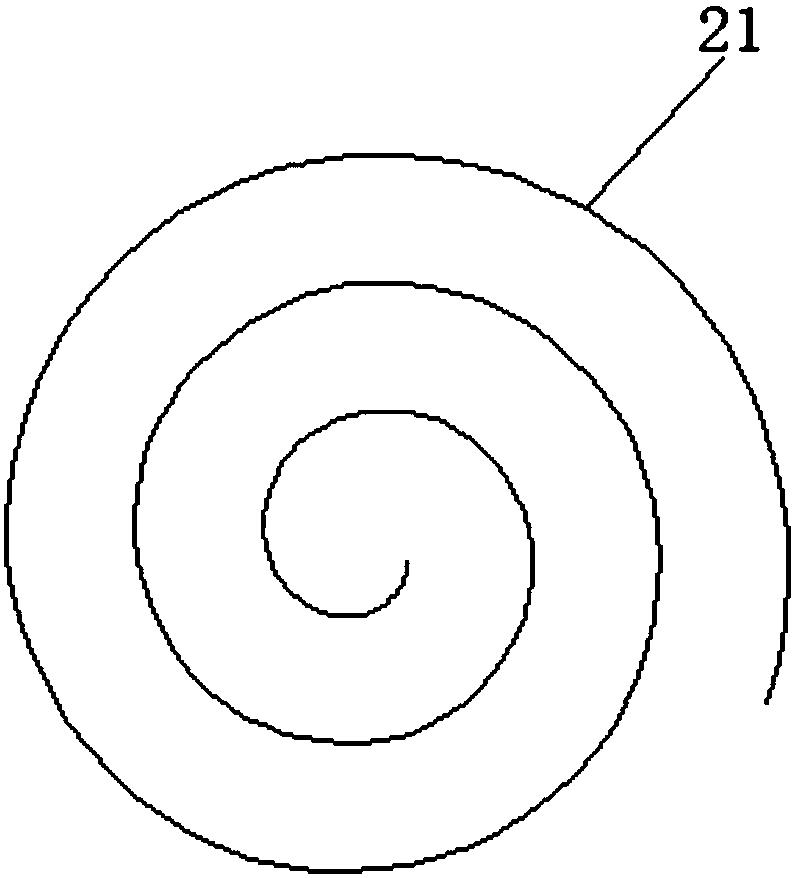

[0032] see Figure 1 ~ Figure 3 , a kind of environment-friendly geothermal floor that can improve indoor air quality provided by the present invention, said geothermal floor comprises: surface layer board 1; Laminated with the surface plate 1, the bottom of the bottom plate 2 is provided with an accommodating groove 21 for accommodating the heating pipeline. A number of heat conduction holes (not shown) are opened on the upper surface of the plate 2, and the heat conduction holes are arranged at intervals along a plane spiral. The inner wall of the trough 21 is sequentially coated with an insulating layer (not shown), a moisture-proof layer (not shown) and an antibacterial layer (not shown) from inside to outside; the upper surface of the surface board 1 is coated sequentially from bottom to top There is a wear-resistant layer 4 and a formaldehyde adsorption layer 5; the adhesive layer includes the following components by weight: acrylic modified epoxy resin: 45 parts, silan...

Embodiment 2

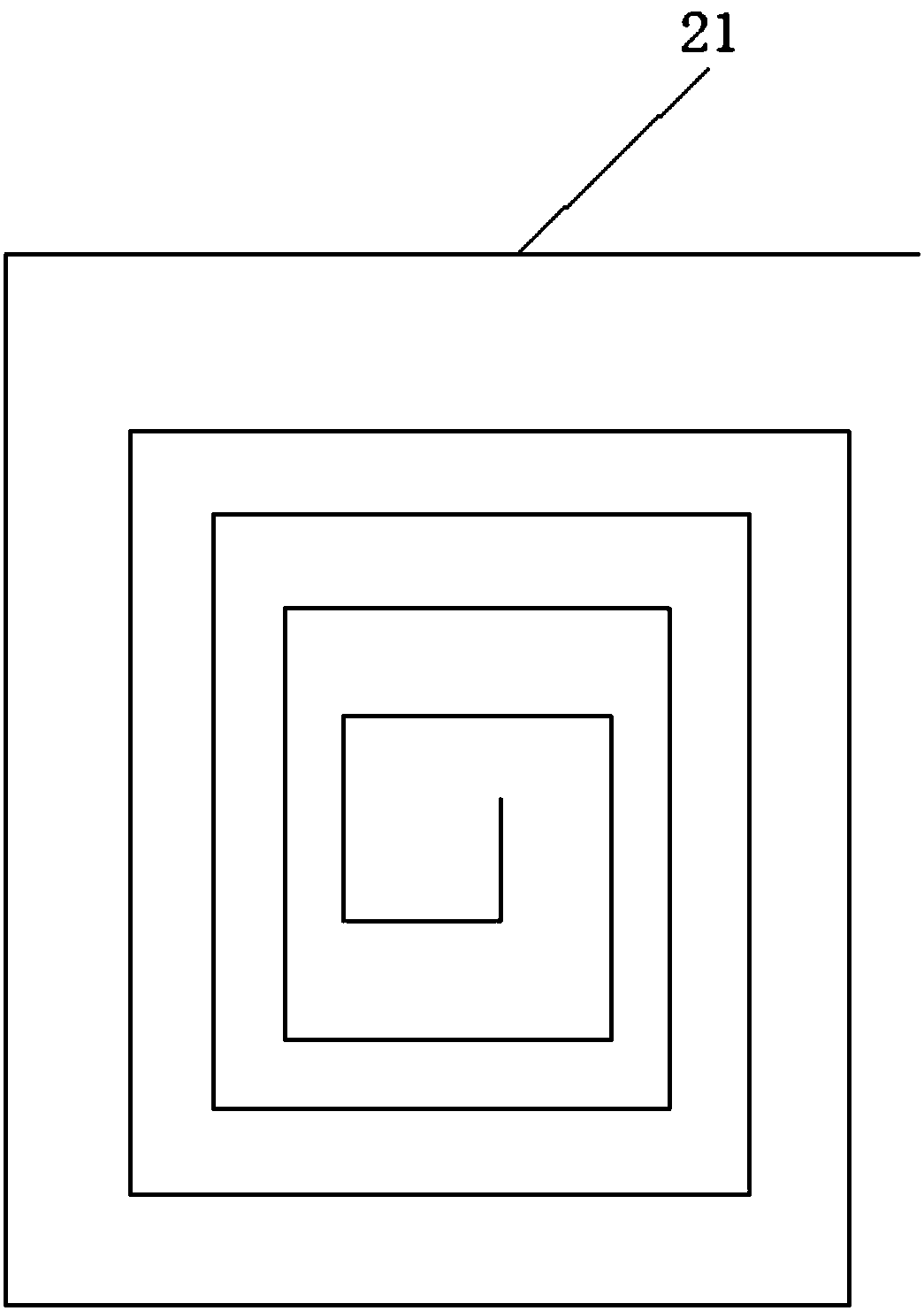

[0042] refer to Figure 4 The accommodating groove is meanderingly opened on the bottom surface of the base plate in a wave shape, and correspondingly, the heat conduction holes are opened on the upper surface of the base plate at intervals along the wave shape. All the other are with embodiment 1.

Embodiment 3

[0044] The adhesive layer includes the following components by weight: acrylic modified epoxy resin: 40 parts, silane coupling agent: 15 parts, methyl cellulose: 25 parts, N-methylpyrrolidone: 5 parts, o-phenyl Dibutyl diformate: 15 parts, graphene: 10 parts, modified ammonium polyphosphate: 20 parts, nano-silica: 10 parts, nano-alumina: 10 parts, methacrylic acid: 5 parts, antioxidant: 1 parts, thickener: 5 parts, curing agent: 5 parts, deionized water: 60 parts. All the other are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com