Environment-friendly super-wide intelligent harrow-tooth conveyor

A conveyor and rake tooth technology, applied in the field of environmentally friendly ultra-wide intelligent rake tooth conveyor, can solve the problems of serious dust phenomenon, poor fluidity, and failure to pass the environmental impact assessment, so as to improve the driving power, avoid the phenomenon of dust, and expand the conveying range. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

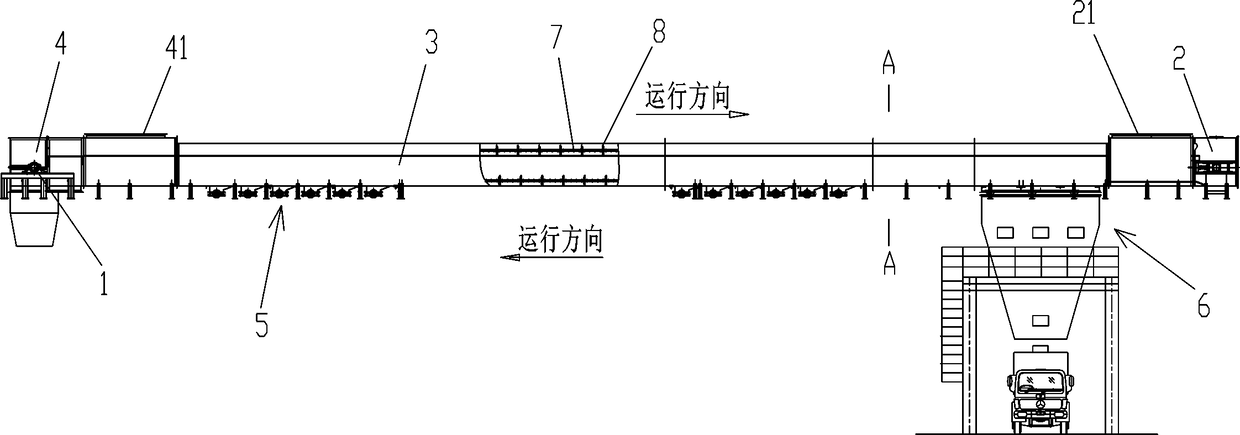

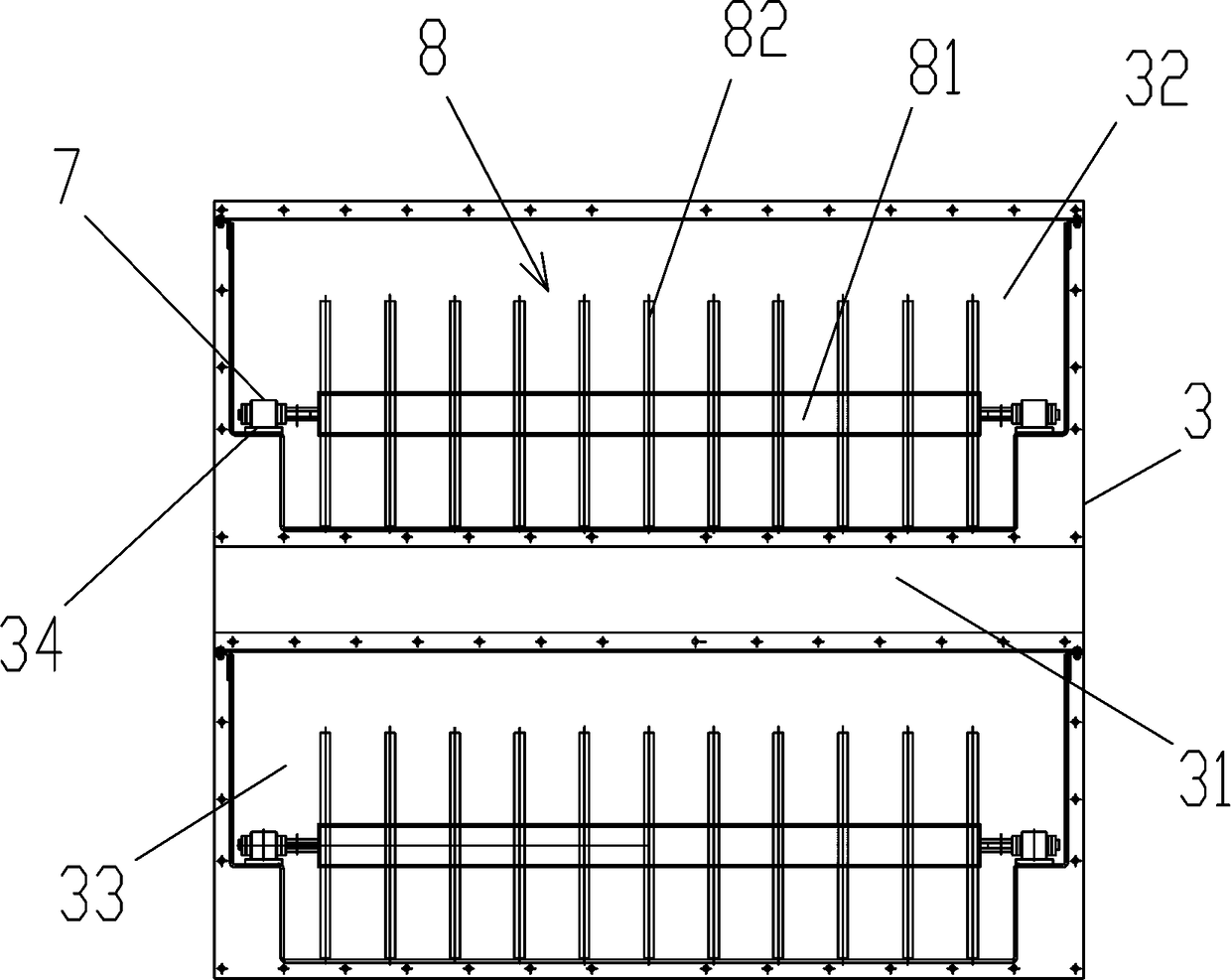

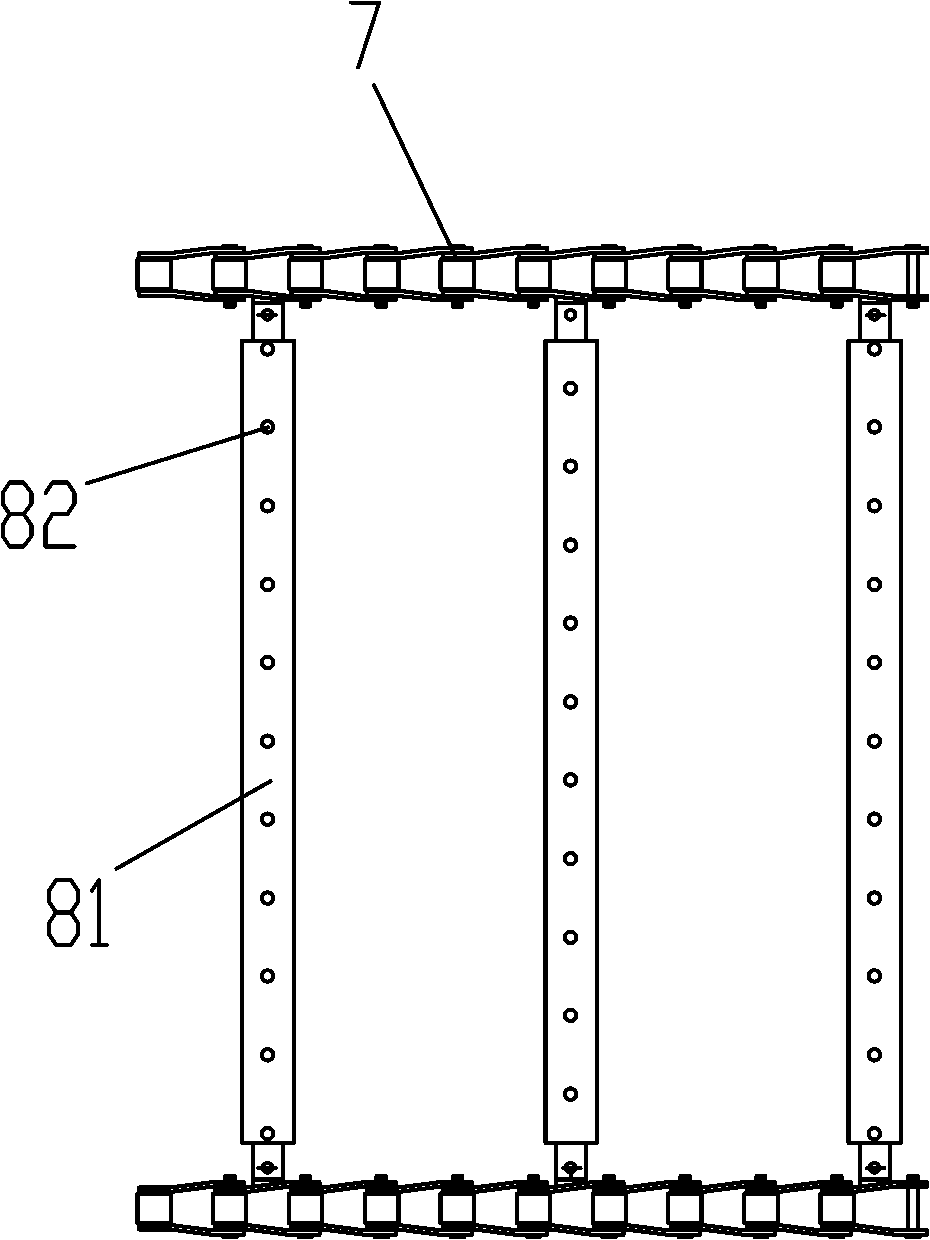

[0059] Such as Figures 1 to 5 As shown, an environmentally friendly ultra-wide intelligent rake tooth conveyor includes a scraper chain, a head 4, a middle section 3, a tail 2, a drive unit 1 and a controller. The controller is a PLC controller, and the drive unit 1 includes a variable frequency motor. 12 and reducer 13, the PLC controller controls the frequency conversion motor 12, to control the start and stop of the conveyor; the middle section 3 is provided with an isolation section 31, and the isolation section 31 separates the middle section 3 into a feed channel 32 and a discharge channel 33, Unloading device 5 is installed on discharge channel 33, is all provided with two guide rails 34 in feed channel 32 and discharge channel 33, as image 3 Among them, the cross-sectional shape of the feed channel 32 and the discharge channel 33 is a "convex" shape, and two guide rails 34 are arranged on the waistcoats on both sides of the "convex"-shaped structure. The scraper chai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com