Cooling method for improving quality of titanium dioxide

A cooling method, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of lattice defects, pigment performance degradation, poor quality, etc., to avoid lattice defects, improve brightness and whiteness, The effect of improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

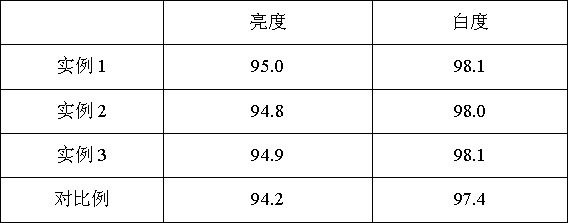

Embodiment 1

[0014] The salt-treated filter cake before the kiln is sent to the rotary kiln by screw for dehydration and desulfurization and crystal transformation. The rotary kiln shaking head temperature is controlled at 960~980°C, and it is calcined until the rutile content is 90%. Then it is sent to the slow cooling device for slow cooling and aging. , Cool slowly to 900°C within 4 hours, then enter the rapid cooling device, cool to below 50°C, obtain high-brightness and high-whiteness kiln products, and enter the subsequent crushing coating.

Embodiment 2

[0016] The salt-treated filter cake before the kiln is sent to the rotary kiln by screw for dehydration and desulfurization and crystal transformation. The rotary kiln shaking head temperature is controlled at 960~980°C, and it is calcined until the rutile content is 92%. Then it is sent to the slow cooling device for slow cooling and aging. , Slowly cool to 900°C within 2 hours, then enter the rapid cooling device, cool to below 50°C, obtain high-brightness and high-whiteness kiln products, and enter the subsequent crushing coating.

Embodiment 3

[0018] The salt-treated filter cake before the kiln is sent to the rotary kiln by screw for dehydration and desulfurization, crystal transformation, controlled rotary kiln shaking head temperature 960~980°C, calcined until the rutile content is 96%, and then sent to the slow cooling device for slow cooling and aging , Slowly cool to 850°C within 1 hour, then enter the rapid cooling device, cool to below 50°C, obtain high-brightness and high-whiteness kiln products, and enter the subsequent crushing coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com