Catalyst composition for olefin polymerization, use thereof and method for polymerization of conjugated diene monomer

A technology of olefin polymerization and composition, which is applied in the field of conjugated diene monomer polymerization, can solve the problems of catalyst deactivation, difficult realization of copolymerization, easy destruction of catalytic active centers, etc., and achieve high content of cis structure and high conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

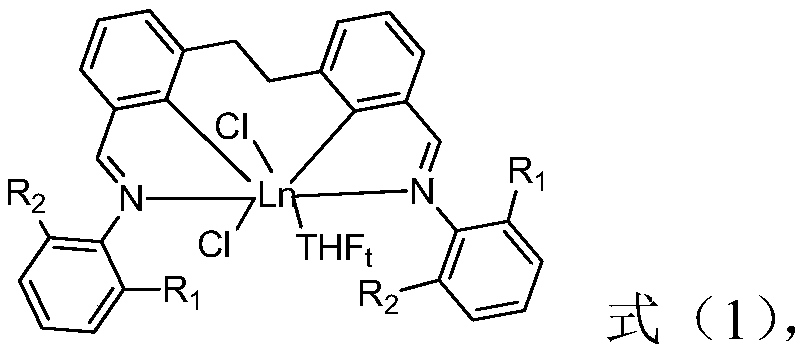

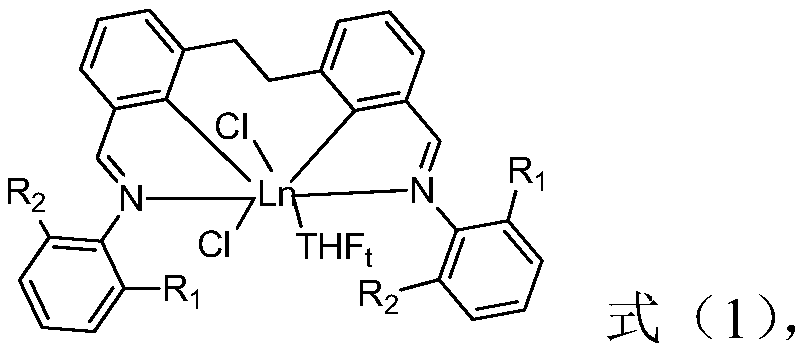

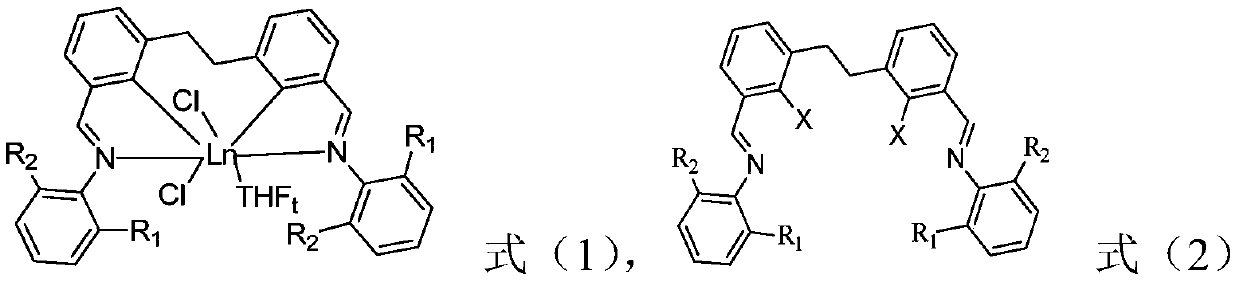

[0108] (1) prepare the compound of structure shown in formula (2), wherein, X is Br; R 1 for CH 3 ; 2 for CH 3 .

[0109] 1. Dissolve 2,6-dimethylbromobenzene (10mmol), NBS (30mmol) and AIBN (0.2mmol) in 50mL of CCl 4 After reflux for 10 hours, cool and filter, and spin the filtrate to dryness. To this was added 88% by weight formic acid (35 mL) and reflux was continued for 12 h. After that, the solvent was evaporated under reduced pressure, and the volume ratio was 1:1.5 with CH 2 Cl 2 / H 2 O extraction, the organic phase was separated and washed with anhydrous Na 2 SO 4 Dry, then use petroleum ether: CH 2 Cl 2 =5:1 (volume ratio) column chromatography separation to obtain the intermediate product 2-bromo-3-benzyl bromide-benzaldehyde;

[0110] 2. Dissolve 2-bromo-3-benzyl bromide-benzaldehyde (3.6mmol) in 30mL of methanol, then add 2,6-dimethyl-aniline (3.6mmol), and add acetic acid to make the pH of the solution After reacting at 25°C for 8 hours, the precipita...

preparation example 2

[0118] (1) prepare the compound of structure shown in formula (2), wherein, X is Br; R 1 for CH 3 CH 2 ; 2 for CH 3 CH 2 .

[0119] The compound with the structure represented by formula (2) was prepared by a method similar to Preparation Example 1 to obtain a bis-Schiff base compound with a yield of 75%.

[0120] The characterization data of gained bis-Schiff base compound are as follows:

[0121] 1 H NMR (CDCl 3 ,400MHz,δ,ppm):8.74(s,2H),8.14(d,2H),7.37(t,4H),7.10(d,4H),7.18(t,2H),2.61(m,8H), 1.36(s,12H).

[0122] Elemental Analysis: C 36 h 38 N 2 Br 2 Calculated: C, 65.67; H, 5.78; N, 4.26. Found: C, 65.69; H, 5.78; N, 4.23.

[0123] (2) The compound with the structure shown in formula (1) was prepared by a method similar to Preparation Example 1, wherein Ln is Nd.

[0124] Dissolve the obtained bis-Schiff base compound (1 mmol) in THF to form a 0.04M solution, add butyllithium (1.05 mmol) in hexane solution (20 mL), stir the reaction at minus 78 ° C for 1 h...

preparation example 3

[0126] (1) prepare the compound of structure shown in formula (2), wherein, X is Br; R 1 for CH(CH 3 ) 2 ; 2 for CH(CH 3 ) 2 .

[0127] The compound represented by the formula (2) was prepared by a method similar to that of Preparation Example 1 to obtain a bis-Schiff base compound with a yield of 73%.

[0128] The characterization data of gained bis-Schiff base compound are as follows:

[0129] 1 H NMR (CDCl3 ,400MHz,δ,ppm):8.74(s,2H),8.14(d,2H),7.37(t,4H),7.08~7.12(m,6H),3.02~3.08(m,4H),1.23(d ,12H).

[0130] Elemental Analysis: C 40 h 46 N 2 Br 2 Calculated: C, 67.24; H, 6.44; N, 3.92. Found: C, 67.23; H, 6.44; N, 3.91.

[0131] (2) The compound with the structure shown in formula (1) was prepared by a method similar to Preparation Example 2, wherein Ln is Nd.

[0132] The bis-Schiff base rare earth complex P3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com