Method for stably preparing high-nickel ternary battery electrode material by doping in advance

A ternary lithium battery and electrode material technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor processing stability and difficult control of high-nickel ternary materials, so as to overcome poor processing stability and prevent doping. Phase separation, the effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

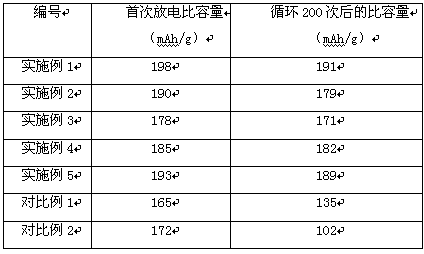

Examples

Embodiment 1

[0036] A method for predoping and stably preparing electrode materials for high-nickel ternary lithium batteries. First, take a mass concentration of 60% nickel sulfate solution, 65% cobalt sulfate solution, and 80% sulfuric acid in a molar ratio of 8:1:1. Manganese solution, then Mg-Al-F is mixed into nickel sulfate solution, the mass fraction of Mg-Al-F doped nickel sulfate solution is 15%, Ti-F is mixed into manganese sulfate solution, cobalt sulfate solution, Ti-F The mass fractions of doped manganese sulfate solution and cobalt sulfate solution are 10% and 5% respectively, and the doped nickel sulfate solution is maintained in ammonia water with a mass concentration of 60%, and the doped manganese sulfate solution and cobalt sulfate solution are maintained in three Conservation in ethanolamine; Put the doped solution into polyacrylamide-graphene colloid respectively to form a colloid, the doped nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution an...

Embodiment 2

[0038] A method for predoping and stably preparing electrode materials for high-nickel ternary lithium batteries. First, take a mass concentration of 60% nickel sulfate solution, 70% cobalt sulfate solution, and 80% sulfuric acid in a molar ratio of 8:1:1. Manganese solution, then Mg-Al-F is mixed into nickel sulfate solution, the mass fraction of Mg-Al-F doped nickel sulfate solution is 20%, Ti-F is mixed into manganese sulfate solution, cobalt sulfate solution, Ti-F The mass fractions of doped manganese sulfate solution and cobalt sulfate solution are 10% and 5% respectively, and the doped nickel sulfate solution is maintained in ammonia water with a mass concentration of 60%, and the doped manganese sulfate solution and cobalt sulfate solution are maintained in three Conservation in ethanolamine; Put the doped solution into polyacrylamide-graphene colloid respectively to form a colloid, the doped nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution an...

Embodiment 3

[0040] A method for predoping and stably preparing electrode materials for high-nickel ternary lithium batteries. First, take a mass concentration of 75% nickel sulfate solution, 70% cobalt sulfate solution, and 82% sulfuric acid in a molar ratio of 8:1:1. Manganese solution, then Mg-Al-F is mixed into nickel sulfate solution, the mass fraction of Mg-Al-F doped nickel sulfate solution is 20%, Ti-F is mixed into manganese sulfate solution, cobalt sulfate solution, Ti-F The mass fractions of doped manganese sulfate solution and cobalt sulfate solution are 12% and 8% respectively, and the doped nickel sulfate solution is maintained in ammonia water with a mass concentration of 70%, and the doped manganese sulfate solution and cobalt sulfate solution are maintained in three Conservation in ethanolamine; Put the doped solution into polyacrylamide-graphene colloid respectively to form a colloid, the doped nickel sulfate solution, cobalt sulfate solution, manganese sulfate solution an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com