Sugar-free biscuits and processing method thereof

A processing method and biscuit technology, applied in the field of sugar-free biscuits and their processing, can solve the problems of slow development of sugar-free biscuits and failure to satisfy consumers, and achieve the effect of complete and beautiful appearance, easy control and high nutritional content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

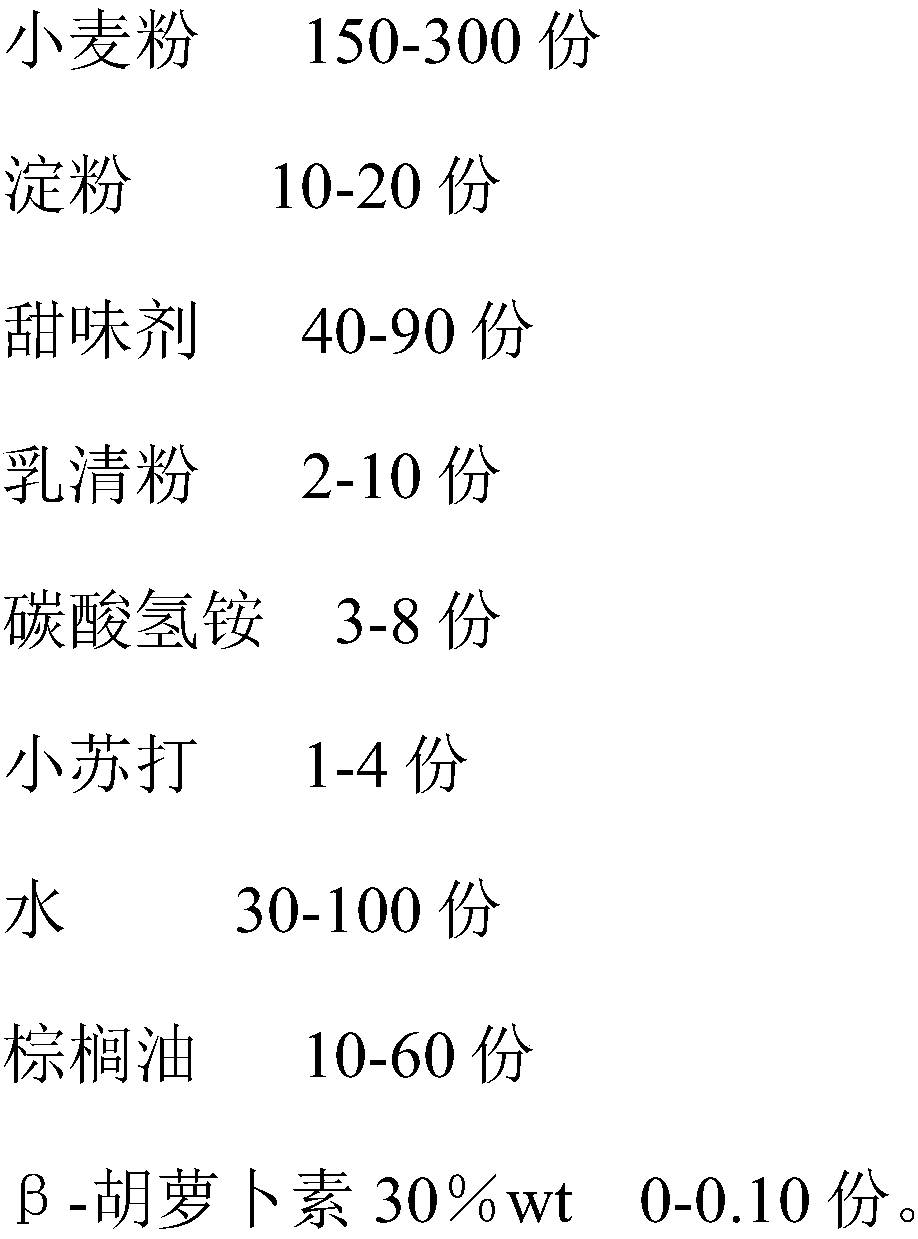

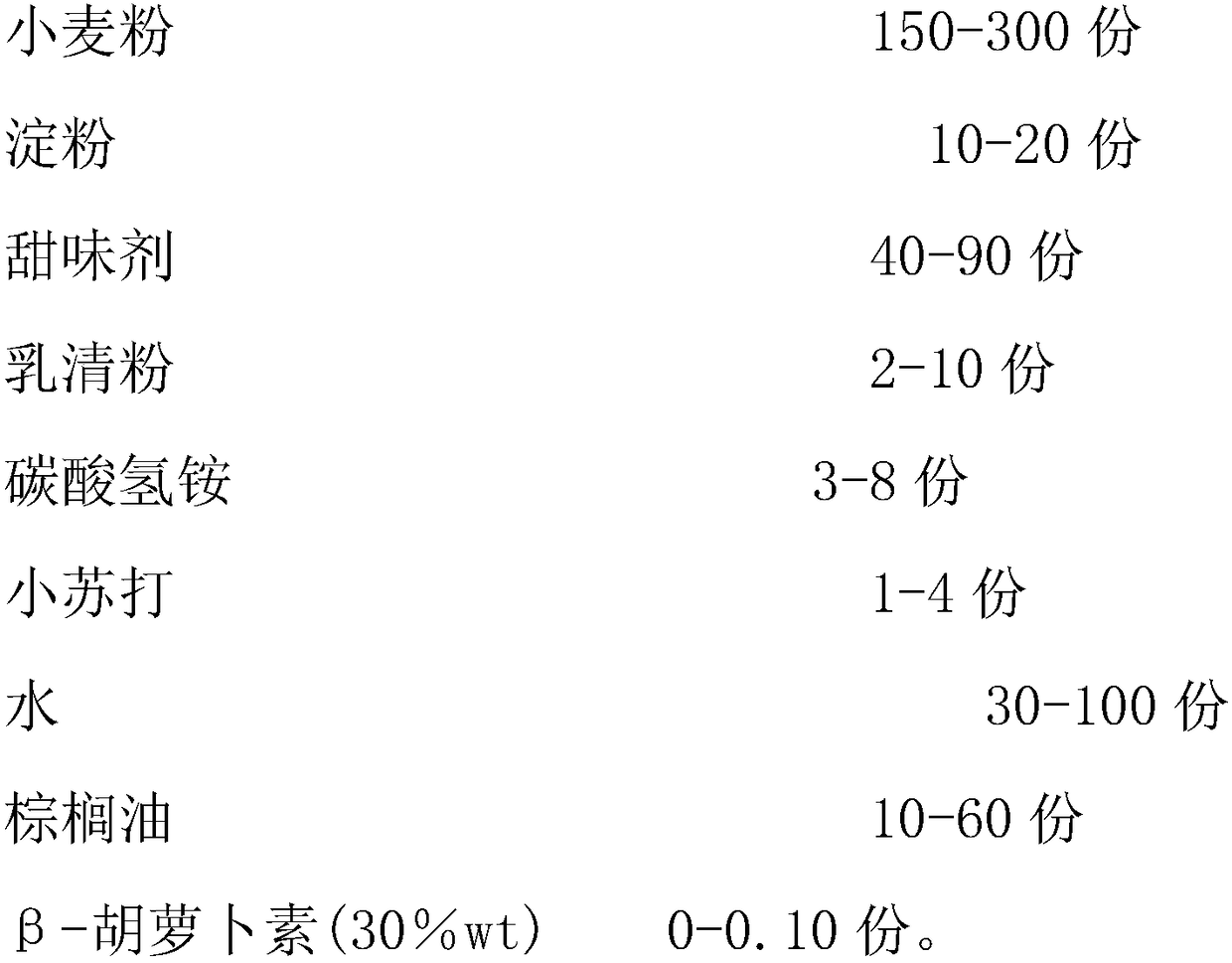

Method used

Image

Examples

Embodiment 1

[0029] First, 29 kilograms of palm oil, 10 grams of β-carotene (30% wt), 80 kilograms of liquid xylitol, and seaweed polysaccharide are mixed and poured into the mixing tank, and stirred to make it evenly mixed; then add 6.25 kilograms of bicarbonate in the tank Ammonium, 3.5 kg of soda, 3 kg of whey powder, plus 60 kg of water, stir to make it evenly mixed; select 250 kg of crushed and 60-mesh wheat flour, mix with 13 kg of starch, pass through a 10-20 mesh sieve, and add to the mixing tank Mix together, mix the dough and let it rest for 10 minutes. The stirred dough is calendered to obtain green biscuit; the formed green biscuit is baked in an oven, and the biscuit is naturally cooled after being baked to obtain a sugar-free biscuit.

Embodiment 2

[0031] First 60 kilograms of palm oil, 10 grams of β-carotene (30%wt) and 5 kilograms of seaweed polysaccharides, 70 kilograms of liquid xylose are mixed and poured into the mixing tank, and stirred to make it evenly mixed; then add 6 kilograms of ammonium bicarbonate and 3.8 kg of soda, 4 kg of whey powder, plus 60 kg of water, and stir to make it evenly mixed; choose 280 kg of wheat flour that has been crushed and simultaneously added calcium, and passed through a 60-mesh sieve, mixed with 19 kg of starch, passed through a 10-20 mesh sieve and added Stir together in a mixing bowl and let the dough rest for 10 minutes. The kneaded dough is calendered to obtain green biscuit; the formed green biscuit is baked in an oven, cooled naturally to obtain a sugar-free calcium milk biscuit.

Embodiment 3

[0033] First, mix 40 kilograms of palm oil, 10 grams of β-carotene (30%), 10 kilograms of seaweed polysaccharides, and 60 kilograms of liquid xylitol into the mixing tank, and stir to make it evenly mixed; then add 4 kilograms of ammonium bicarbonate and 2.5 kg of soda, 2 kg of whey powder, plus 40 kg of water, stir to make it evenly mixed; select 180 kg of 60-mesh wheat flour after crushing and synchronously adding vitamin C, and mix with 17 kg of starch to pass through a 10-20 mesh sieve Add it to the mixing bowl and stir together, and let the dough rest for 10 minutes. The kneaded dough is calendered to obtain green biscuit; the formed green biscuit is baked in an oven, cooled naturally to obtain vitamin sugar-free biscuit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com