Gradient thermal barrier coating with continuously changing interface composition of double ceramic layers and preparation method thereof

A technology of thermal barrier coating and ceramic layer, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems of multiple coating interfaces, complex thermodynamic behavior, complex preparation process, etc., and achieve thermal shock resistance Effect of life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0015] The gradient thermal barrier coating in which the composition of the double ceramic layer interface of the present invention is continuously changing is preferably implemented as follows:

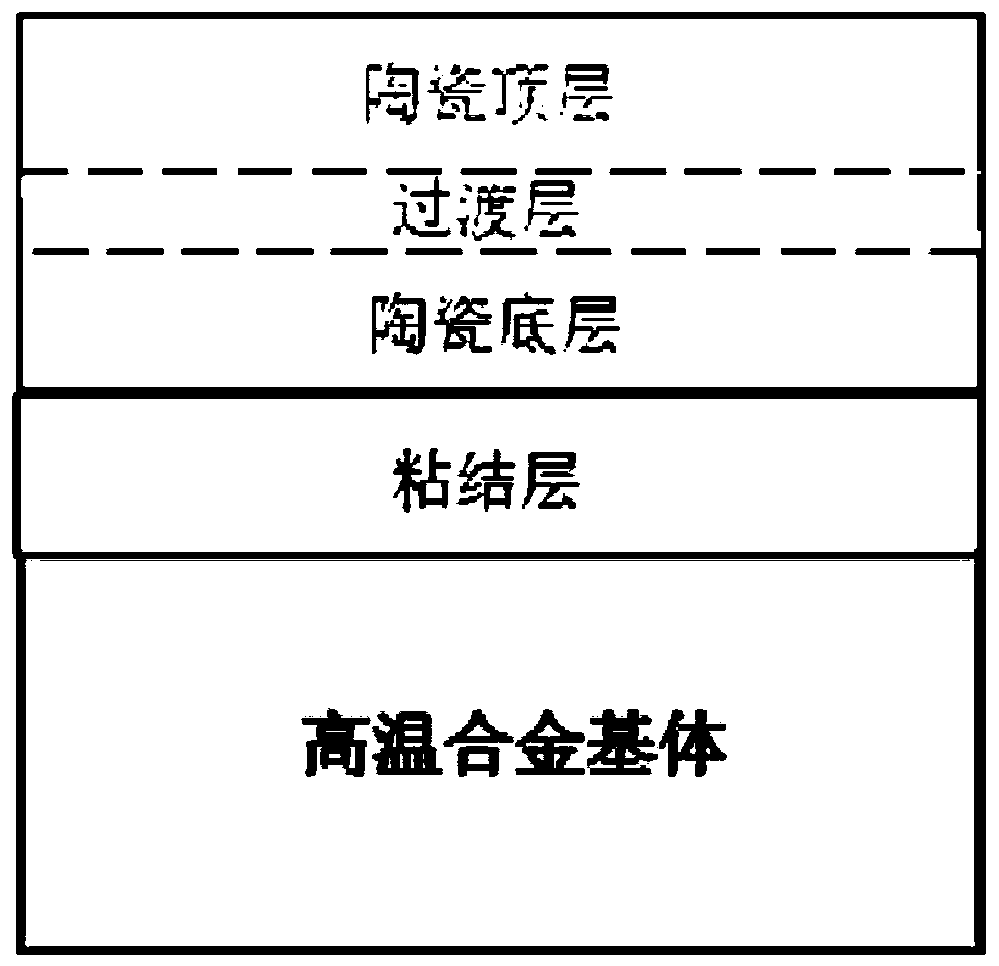

[0016] Such as figure 1 As shown, it includes a substrate, an adhesive layer, a ceramic bottom layer, a transition layer and a ceramic top layer arranged in sequence from bottom to top, and the composition of the transition layer between the ceramic bottom layer and the ceramic top layer is continuously changed in the following manner:

[0017] The composition of the ceramic bottom layer shows a gradient decrease, and the composition of the ceramic top layer shows a gradient increase.

[0018] The ratio of the thickness of the ceramic bottom layer to the ceramic top layer is 0.1-10, and the thickness of the transition layer is 1 / 10-1 / 3 of the total thickness of the ceramic layer.

[0019] The preparation method of the above-mentioned gradient thermal barrier coating in which the int...

specific Embodiment

[0050] The first step is to prepare the superalloy substrate, which is pretreated by sandblasting;

[0051] The second step is to prepare a NiCoCrAlY bonding layer on the substrate.

[0052] (A) The NiCoCrAlY bonding layer was prepared by low-pressure plasma spraying method. The main process parameters are: spraying power 64KW, vacuum chamber pressure 35mbar, powder feeding rate 80g / min, spraying distance 350mm, main gas flow Ar gas 110L / min, H 2 The air flow rate is 6L / min;

[0053] (B) The NiCoCrAlY bonding layer was prepared by supersonic flame spraying method. The main process parameters are: kerosene 25L / h, oxygen 900L / min, combustion chamber pressure 8.4bar, powder feeding rate 80g / min, spraying distance 350mm.

[0054] Grind the prepared bonding layer on 200#, 400#, 600#, 800# sandpaper in turn, and set aside. If other material bonding layer is prepared, such as NiCoCrAlYX (X: one or more of Hf, Ta, Si), the spraying powder used can be changed to NiCoCrAlYX powder. ...

Embodiment 1

[0072] Supersonic flame spraying NiCoCrAlYTa bonding layer + ultra-low pressure plasma physical multiphase deposition interface composition of YSZ / Gd with continuous change on superalloy substrate 2 Zr 2 o 7 double ceramic layer

[0073] The first step is to prepare the superalloy substrate, which is pretreated by sandblasting;

[0074] The second step is to prepare the NiCoCrAlYTa bonding layer by supersonic flame spraying method. The main process parameters are: kerosene 25L / h, oxygen 900L / min, combustion chamber pressure 8.4bar, powder feeding rate 80g / min, spraying distance 350mm. Grind the prepared bonding layer on 200#, 400#, 600#, 800# sandpaper in turn, and set aside.

[0075] The third step is to use ultra-low pressure plasma physical multiphase deposition method to deposit YSZ / Gd with continuous change in interface composition on the bonding layer 2 Zr 2 o 7 Double ceramic layer. Concrete preparation steps are as follows:

[0076] (1) Prepare spray powder: Y...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com