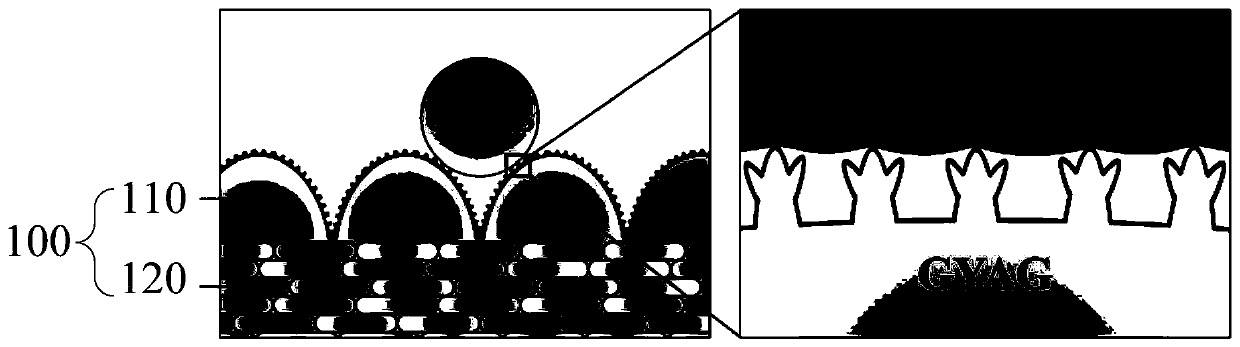

Anti-CMAS double-layer structure protective coating, thermal barrier coating multi-layer structure and preparation method of anti-CMAS double-layer structure protective coating

A double-layer structure, protective coating technology, applied in the direction of coating, metal material coating process, superimposed layer plating, etc., can solve the problem that a single material and a single structure do not have comprehensive performance requirements, failure, low thermal expansion coefficient, etc. problems, to achieve the effect of reducing interface mismatch problems, not easy to change or fail, and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

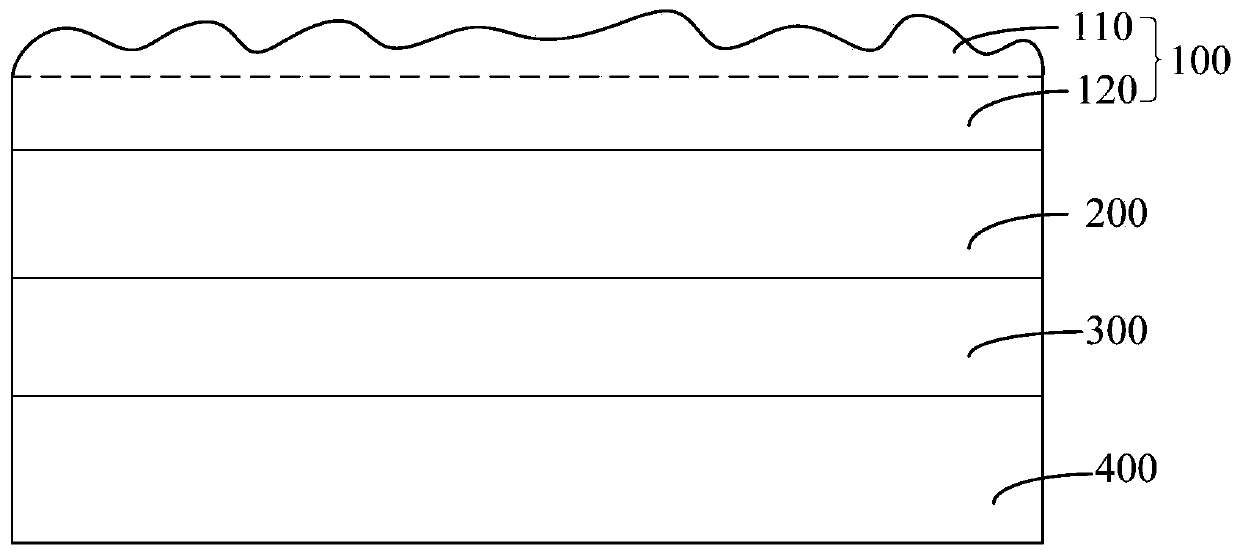

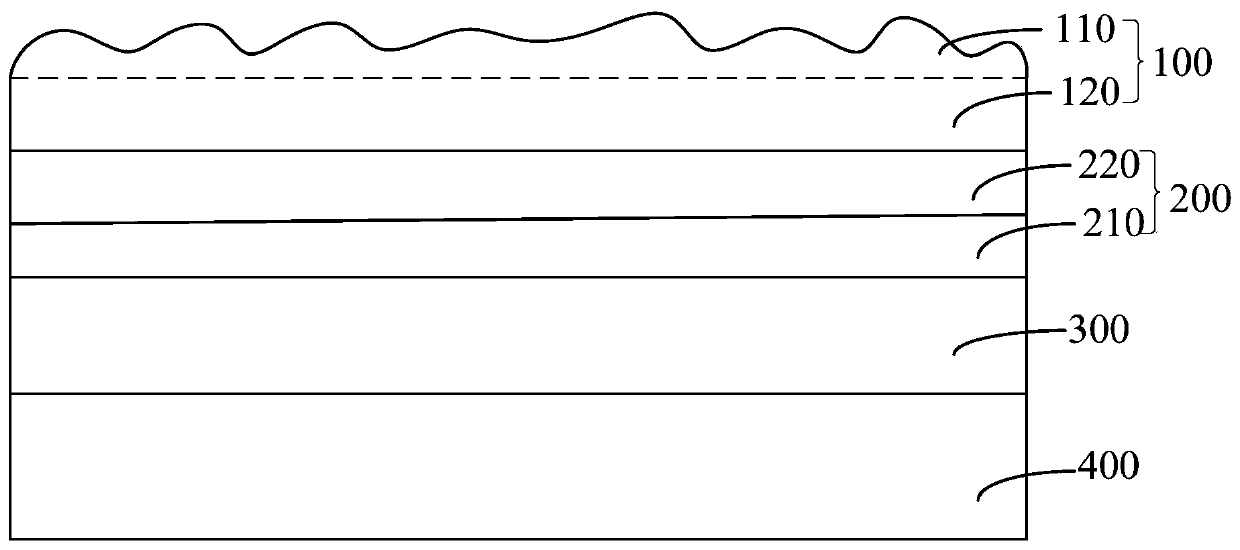

[0058] For the preparation method of the multilayer structure of the thermal barrier coating, the bonding layer 300 can be prepared by electron beam physical vapor deposition (EB-PVD), multi-arc ion plating or aluminizing after electroplating Pt; atmospheric plasma spraying (APS ), electron beam physical vapor deposition (EB-PVD) or plasma physical vapor deposition (PS-PVD) method to prepare the first ceramic layer 210; using electron beam physical vapor deposition or plasma physical vapor deposition method, on the first ceramic layer The second ceramic layer 220 is prepared on the 210; the anti-CMAS double-layer structure protective coating 100 is prepared by plasma physical vapor deposition (PS-PVD).

[0059] Further, the present application also provides a method for preparing a thermal barrier coating multilayer structure with excellent comprehensive performance with an anti-CMAS double-layer structure protective coating 100, comprising the following steps: sequentially for...

Embodiment 1

[0075] Preparation on the surface of the superalloy substrate 400: NiCoCrAlY bonding layer 300 (EB-PVD) + YSZ first ceramic layer 210 (EB-PVD) + YAG anti-CMAS double-layer protective coating (PS-PVD) thermal barrier coating Layer structure, the specific steps are as follows:

[0076] In the first step, the superalloy substrate 400 is ground and then polished, and the surface is pretreated by sandblasting to prepare for coating preparation. Said superalloy is the second generation single crystal alloy (DD6, N5) or directional superalloy DZ125.

[0077] In the second step, the NiCoCrAlY bonding layer 300 is prepared on the substrate 400 by electron beam physical vapor deposition method, and the preparation steps are as follows:

[0078] (1) Use high-purity nickel (Ni), cobalt (Co), chromium (Cr), aluminum (Al) and yttrium (Y), according to the design composition ratio, the Co content is 22wt.%, the Cr content is 20wt.%, and the Al content is 15wt.%, the Y content is 1.46wt.%, an...

Embodiment 2

[0097] On the surface of the superalloy substrate 400, prepare a composite structure thermal barrier coating of PtNiAl bonding layer 300 (electroplating Pt aluminized) + first ceramic layer 210YSZ (PS-PVD) + GYAG protective coating (PS-PVD), the specific steps are as follows :

[0098] In the first step, the superalloy substrate 400 is polished on 120#, 320#, 400#, 800#, 1000#, 1500# water sandpaper in sequence, and then polished, and the surface blasting pretreatment is done for coating preparation. Prepare. Said superalloy is single crystal alloy (DD6, N5, IC21, DD9, IC10) or directional superalloy DZ125 alloy.

[0099] In the second step, a PtNiAl bonding layer 300 is prepared on the alloy substrate 400 by means of electroplating and embedding infiltration. The preparation steps of the PtNiAl bonding layer 300 are as follows:

[0100] Configure the electroplating solution of Pt, the selected composition is: Platinum diammonium nitrite (Pt(NH 3 ) 2 (NO 2 ) 2 ) content ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com