Graphene vertical heterojunction device and preparation method thereof

A heterojunction, graphene technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems affecting device performance, affecting device interface flatness, etc., to achieve flexible preparation, compact structure, and anti-oxidation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

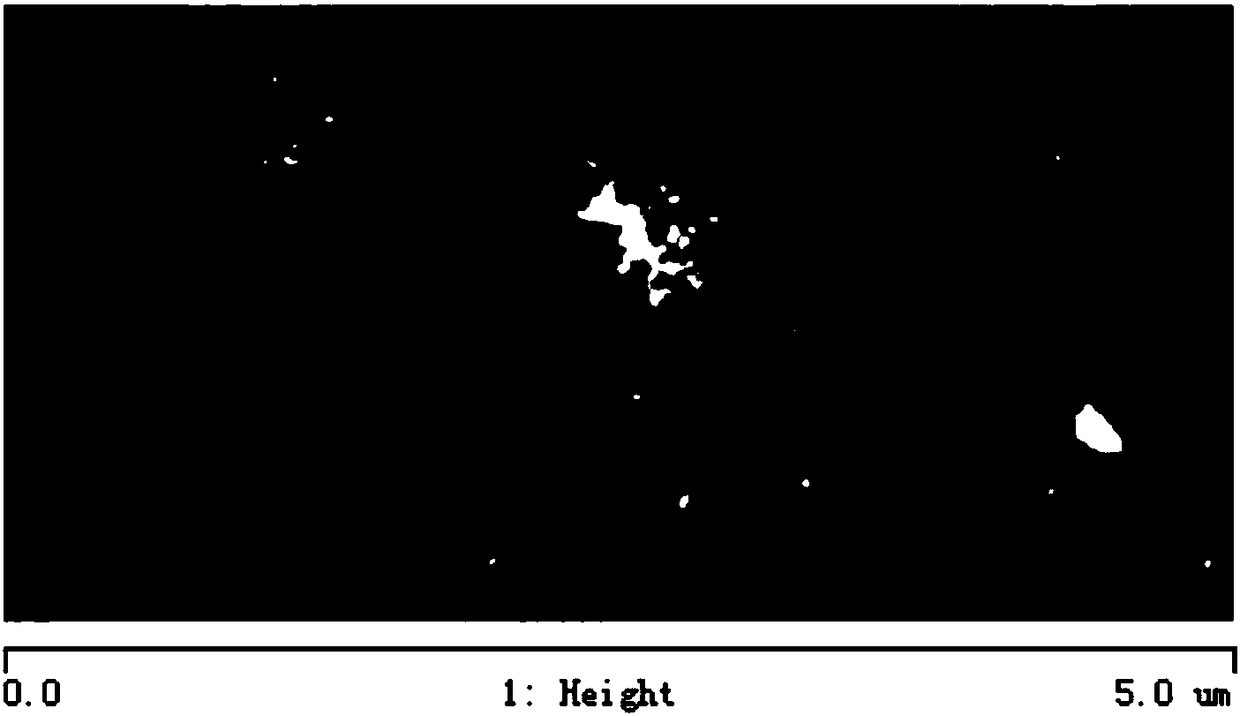

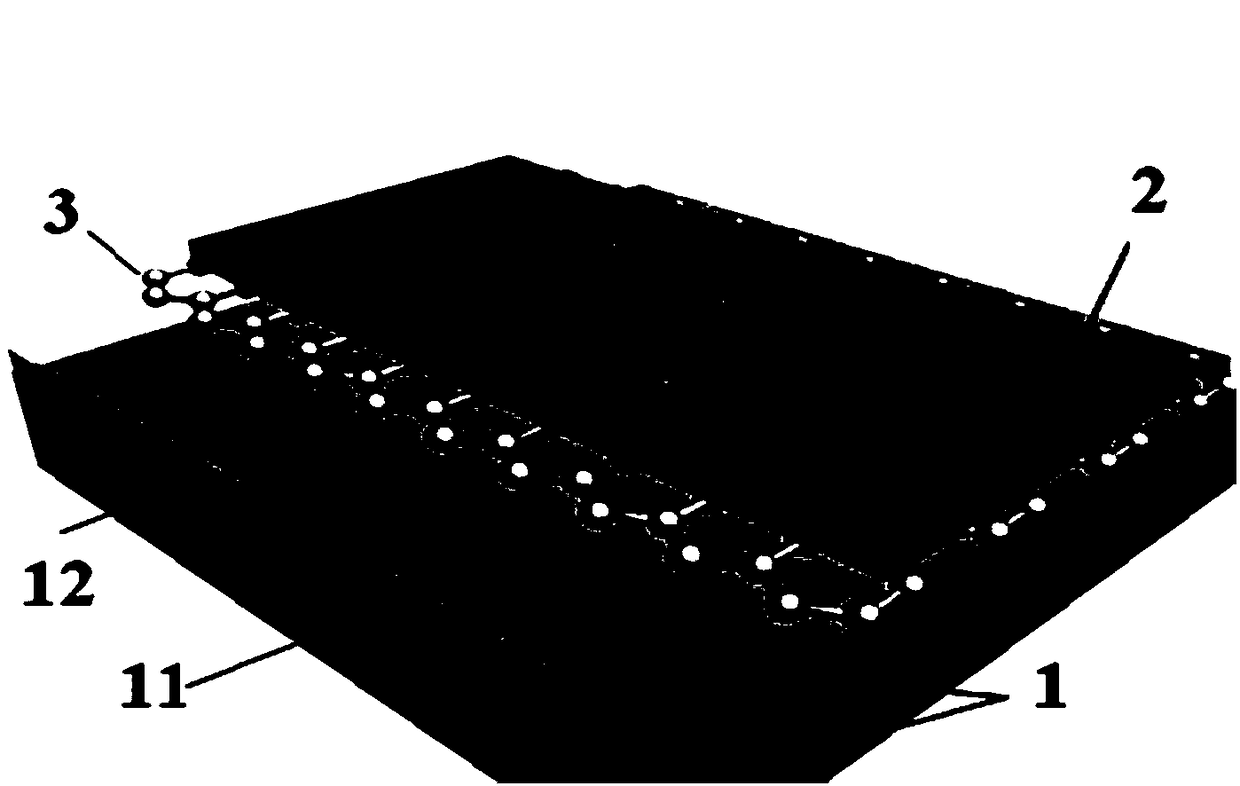

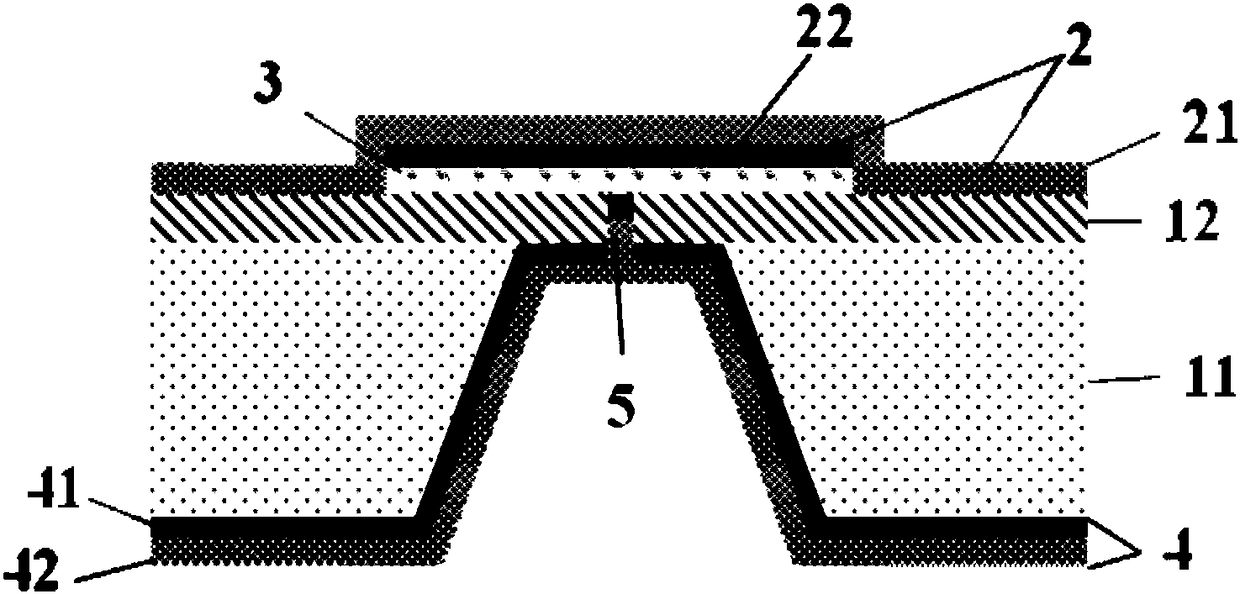

[0040] A graphene vertical heterojunction device of the present invention, specifically a graphene tunnel junction device, such as figure 1 and 2 As shown, it includes a support substrate 1 with nanometer through holes 5 (specifically, a square hole of 910nm×490nm), a graphene layer 3 and a front structural functional layer 2 arranged on the upper surface of the support substrate 1 in sequence, and a nano The back structural functional layer 4 , the front structural functional layer 2 and the rear structural functional layer 4 in the through hole 5 are all physically combined with the graphene layer 3 to form a magnetic tunnel junction.

[0041] In this embodiment, the front structural functional layer 2 includes a front magnetic material layer 22 and a front electrode layer 21 disposed on the upper surface of the front magnetic material layer 22, and the rear structural functional layer 4 includes a rear magnetic material layer 41 and a magnetic material layer disposed on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com