A Passively Suspended Double Drive Low Load Crane

A low-load, passive technology, applied in the direction of load-hanging components, shafts and bearings, bearings, etc., can solve the problems of low magnetic flux utilization, reduced positioning accuracy, and excessive magnetic leakage in space, and achieve fast response and transportation speed. The effect of high positioning accuracy and high magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0012] The preferred embodiment of the passively suspended dual-drive low-load crane of the present invention is:

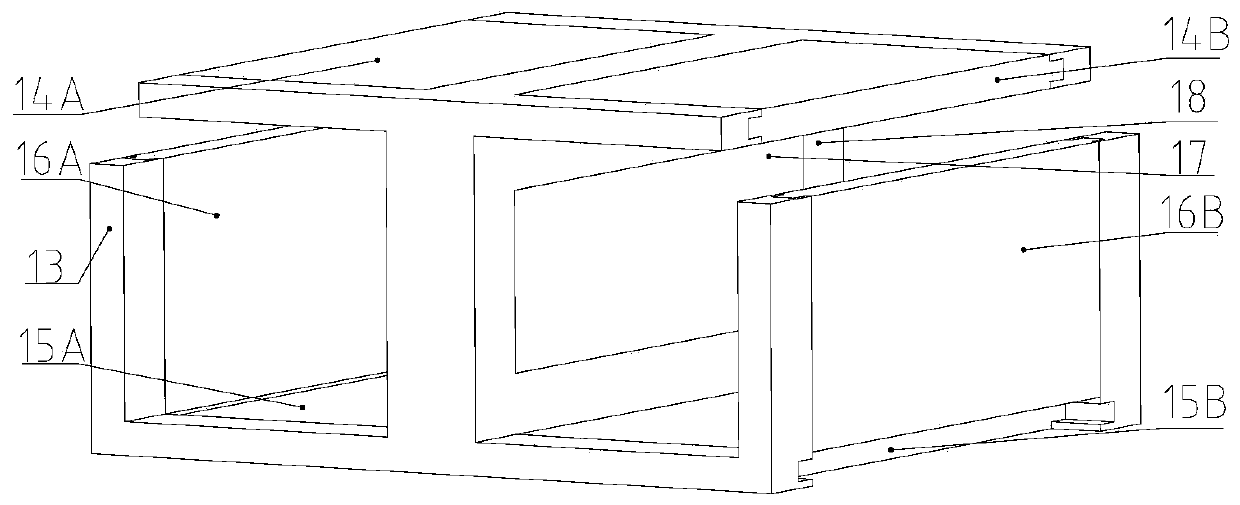

[0013] It is mainly composed of the stator part and the mover part. The stator part includes: the frame, the upper magnetic plate, the upper left permanent magnet of the stator, the upper right permanent magnet of the stator, the upper magnetic isolation positioning block, the left L-shaped magnetic plate, and the right L-shaped magnetic plate , Lower left magnetic positioning block, lower right magnetic positioning block, left permanent magnet of stator, right permanent magnet of stator, lower left permanent magnet of stator, lower right permanent magnet of stator, left magnetic guide rail, right magnetic guide rail, left permanent magnet of left guide rail , upper permanent magnet on the left guide rail, right permanent magnet on the left guide rail, lower permanent magnet on the left guide rail, left permanent magnet on the right guide rail, upper permanent mag...

specific Embodiment

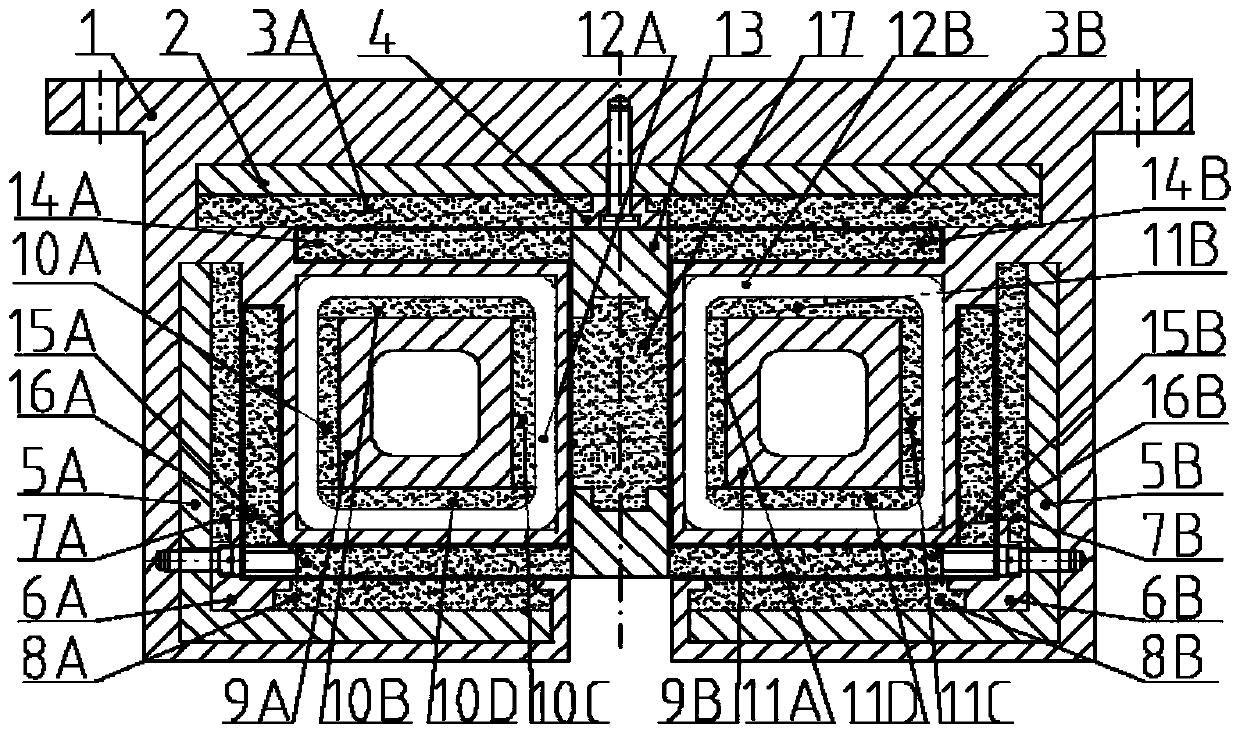

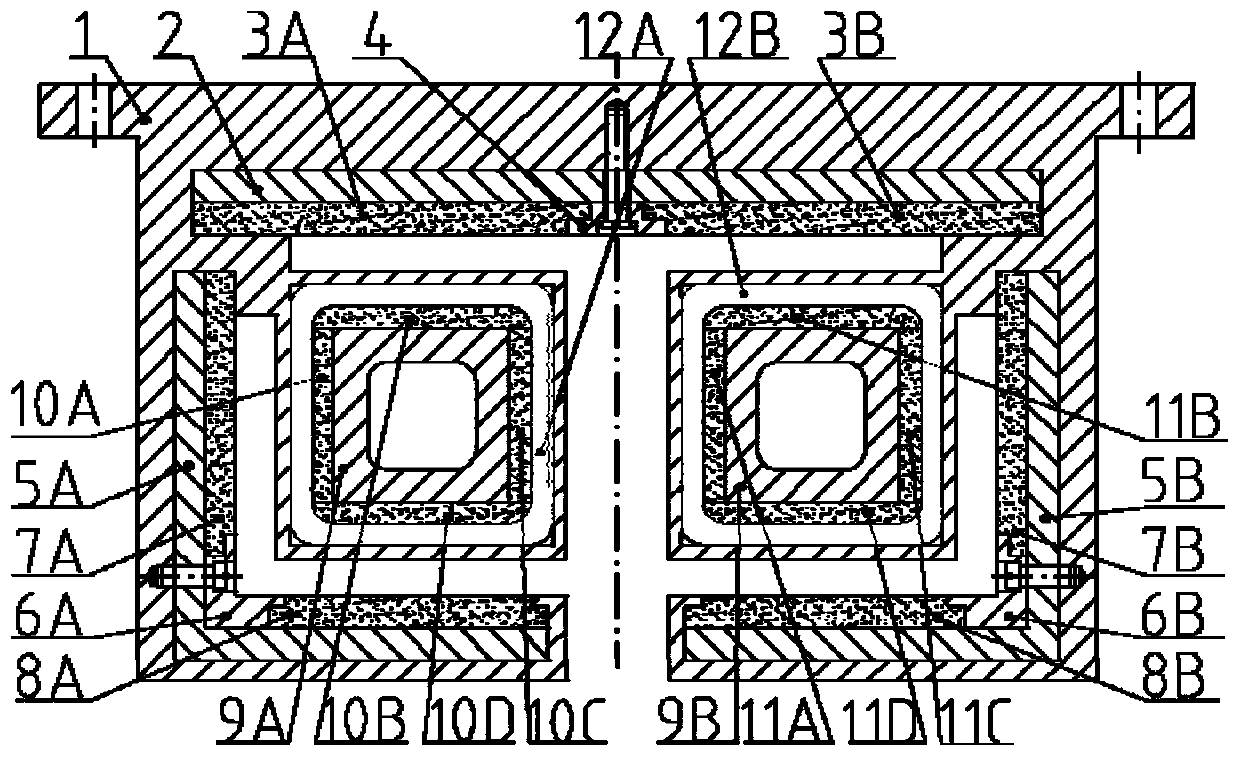

[0020] Such as figure 1 As shown, the passively suspended double-drive low-load crane is mainly composed of a stator part and a mover part. The stator part includes: frame 1, upper magnetic plate 2, stator upper left permanent magnet 3A, stator right upper permanent magnet 3B, upper spacer Magnetic positioning block 4, left L-shaped magnetic plate 5A, right L-shaped magnetic plate 5B, left lower magnetic positioning block 6A, right lower magnetic positioning block 6B, stator left permanent magnet 7A, stator right permanent magnet 7B, stator lower left Permanent magnet 8A, stator right lower permanent magnet 8B, left magnetic guide rail 9A, right magnetic guide rail 9B, left guide rail left permanent magnet 10A, left guide rail upper permanent magnet 10B, left guide rail right permanent magnet 10C, left guide rail lower permanent magnet 10D , the left permanent magnet 11A of the right guide rail, the permanent magnet 11B on the right guide rail, the right permanent magnet 11C o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com