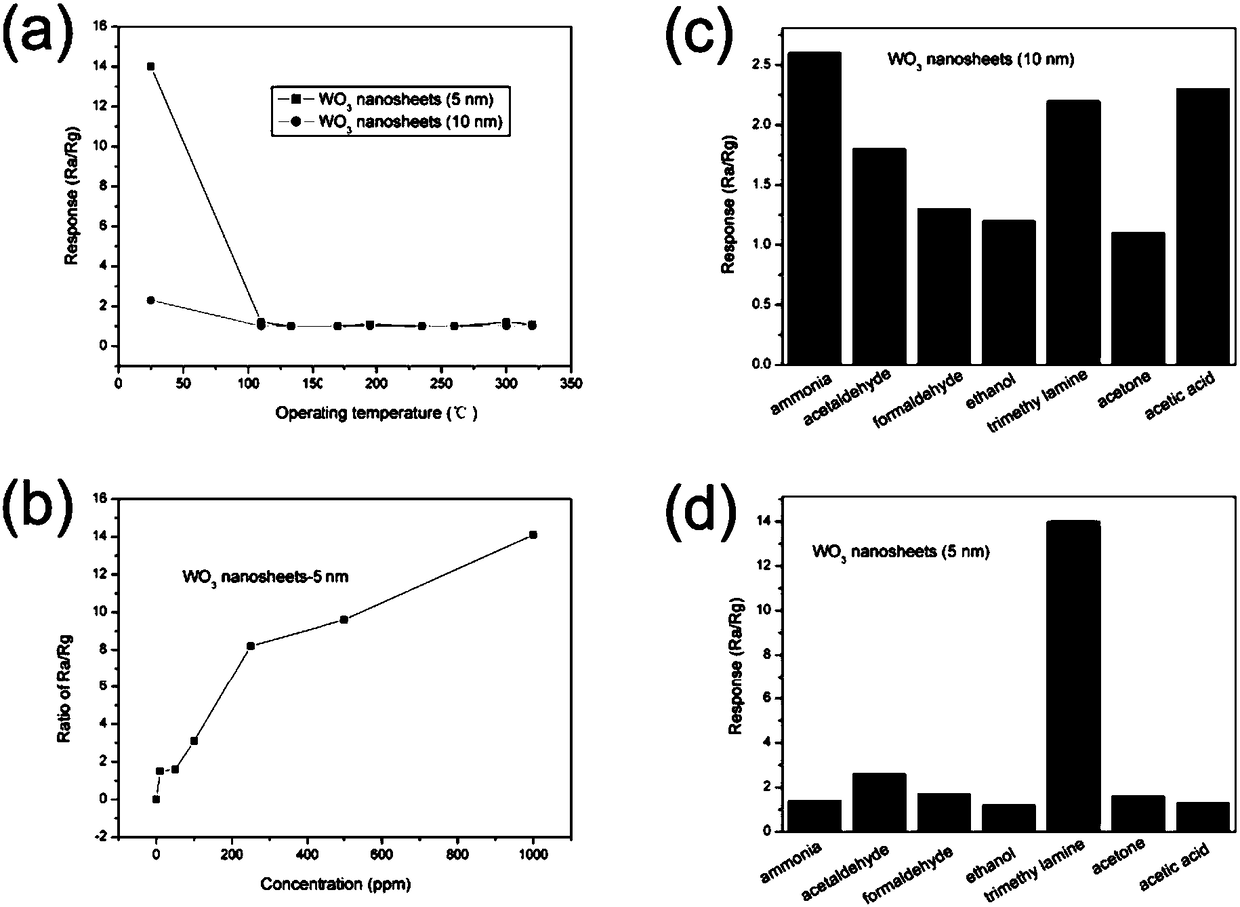

Preparation method of thickness controllable WO3 nano sheet for trimethylamine gas sensor

A gas sensor, nanosheet technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, to achieve the effect of a simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

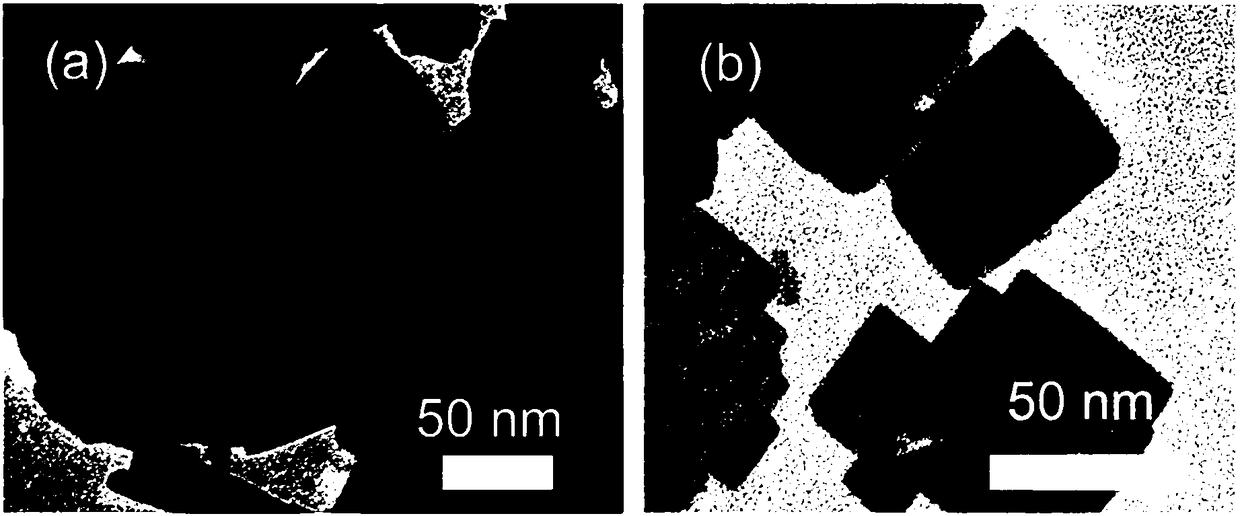

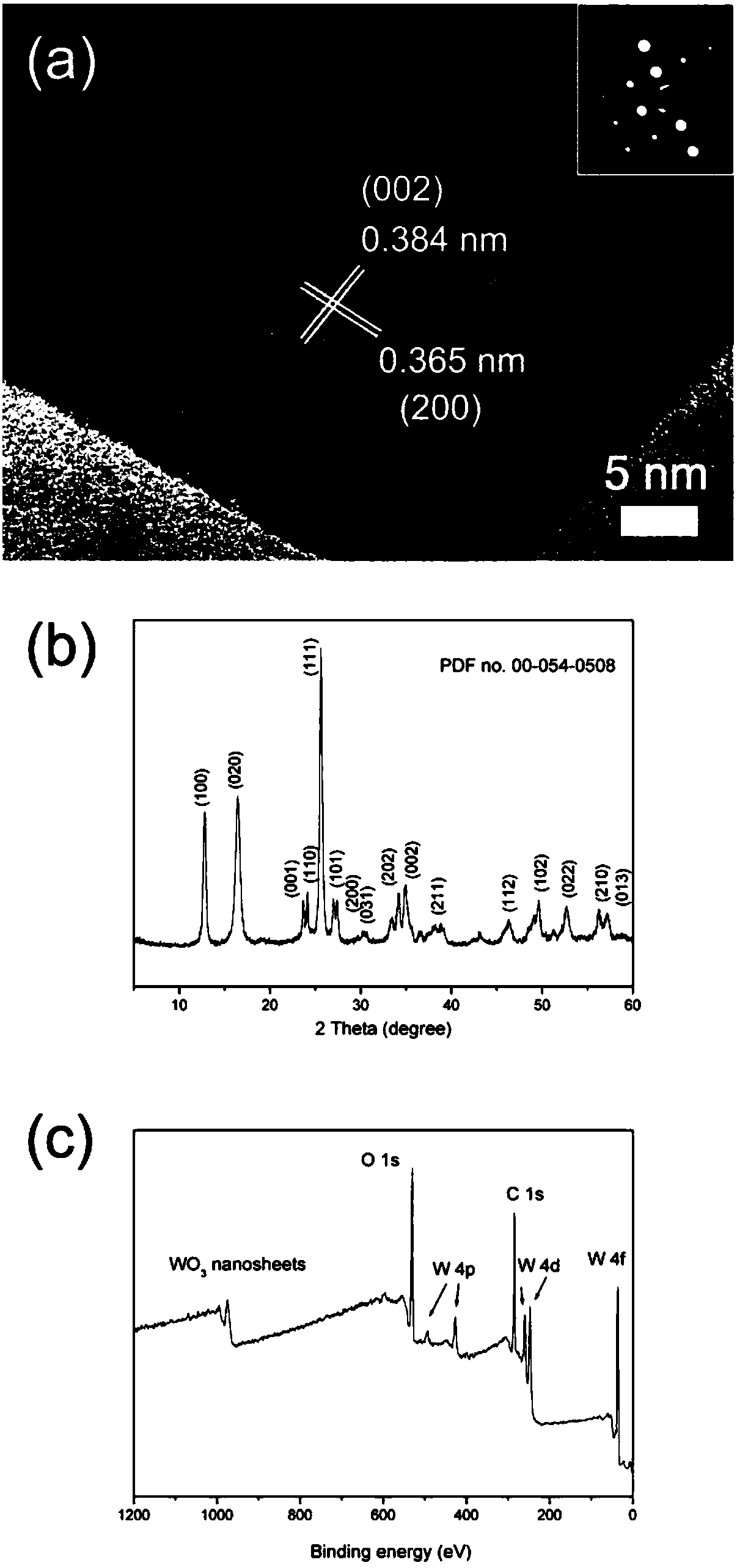

[0030] 1#WO 3 The specific preparation steps of nanosheets are as follows:

[0031] At the initial reaction temperature of 25°C, dissolve 250mg of sodium oleate and 20mg of sodium octanoate into 75mL of nitric acid with a concentration of 4.8mol / L, and add 2mL of sodium tungstate solution with a concentration of 0.1mol / L dropwise under stirring conditions , stirred for 30 minutes, raised the temperature to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheets.

Embodiment 2

[0033] 2#WO 3 The specific preparation steps of nanosheets are as follows:

[0034] At the initial reaction temperature of 25°C, dissolve 250mg of sodium oleate and 150mg of sodium octanoate into 75mL of nitric acid with a concentration of 4.8mol / L, and add 0.5mL of sodium tungstate with a concentration of 0.1mol / L dropwise under stirring. solution, stirred for 30min, heated to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheets.

Embodiment 3

[0036] 3#WO 3 The specific preparation steps of nanosheets are as follows:

[0037] At the initial reaction temperature of 10°C, dissolve 250 mg of sodium oleate and 150 mg of sodium octanoate into 75 mL of nitric acid with a concentration of 4.8 mol / L, and add 0.5 mL of sodium tungstate with a concentration of 0.1 mol / L dropwise under stirring. solution, stirred for 30min, heated to 60°C, stirred for 2 hours, collected the precipitate, washed and dried to obtain WO 3 Nanosheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com