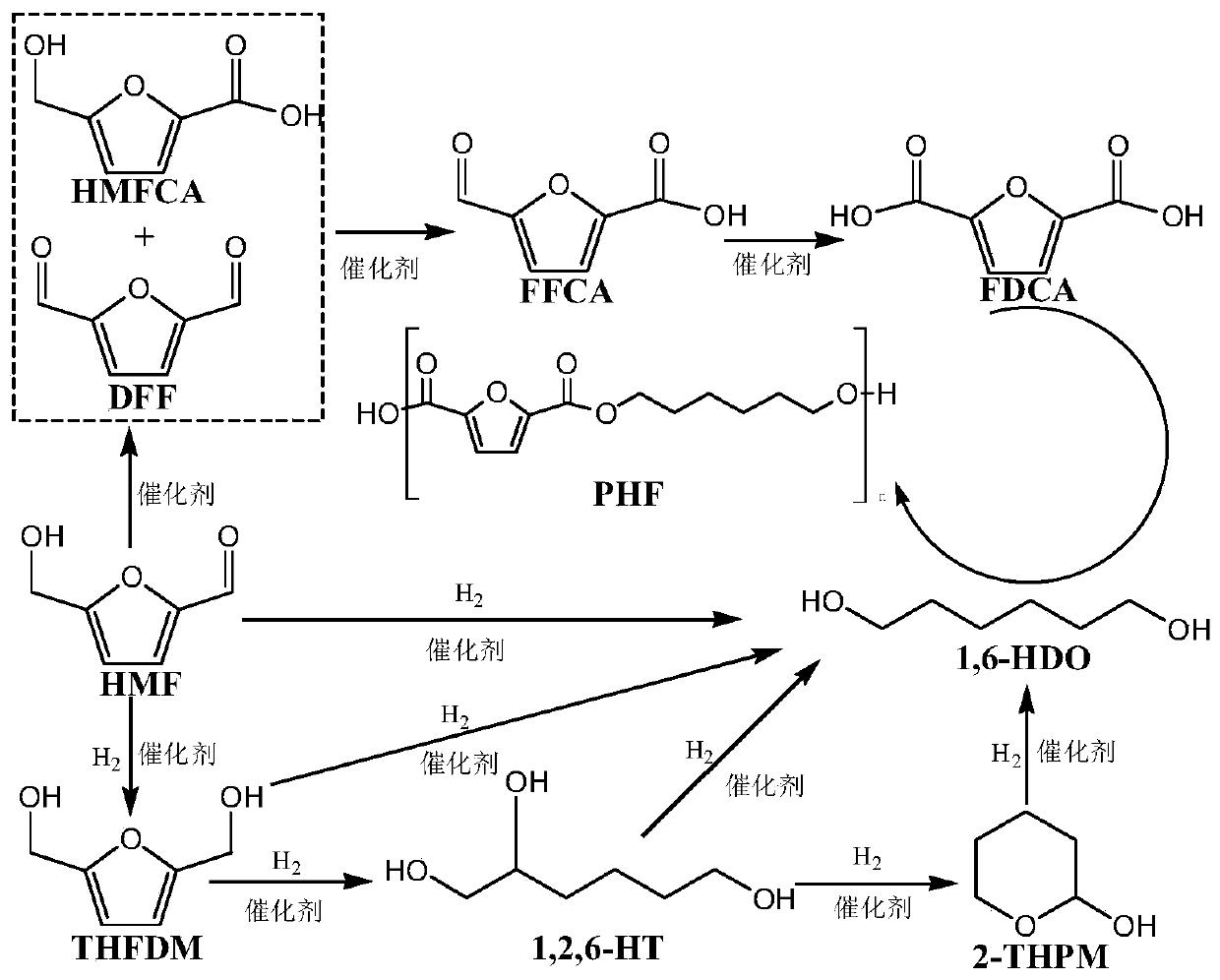

Method for preparing poly-1,6-hexanediol 2,5-furandicarboxylate from biomass

A technology for furandicarboxylic acid and hexylene glycol ester is applied in the field of preparing poly-2,5-furandicarboxylic acid-1,6-hexanediol ester by utilizing biomass, which can solve the problems of poor selectivity and low catalytic activity, and achieves the The effect of low cost, improved stability and improved yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

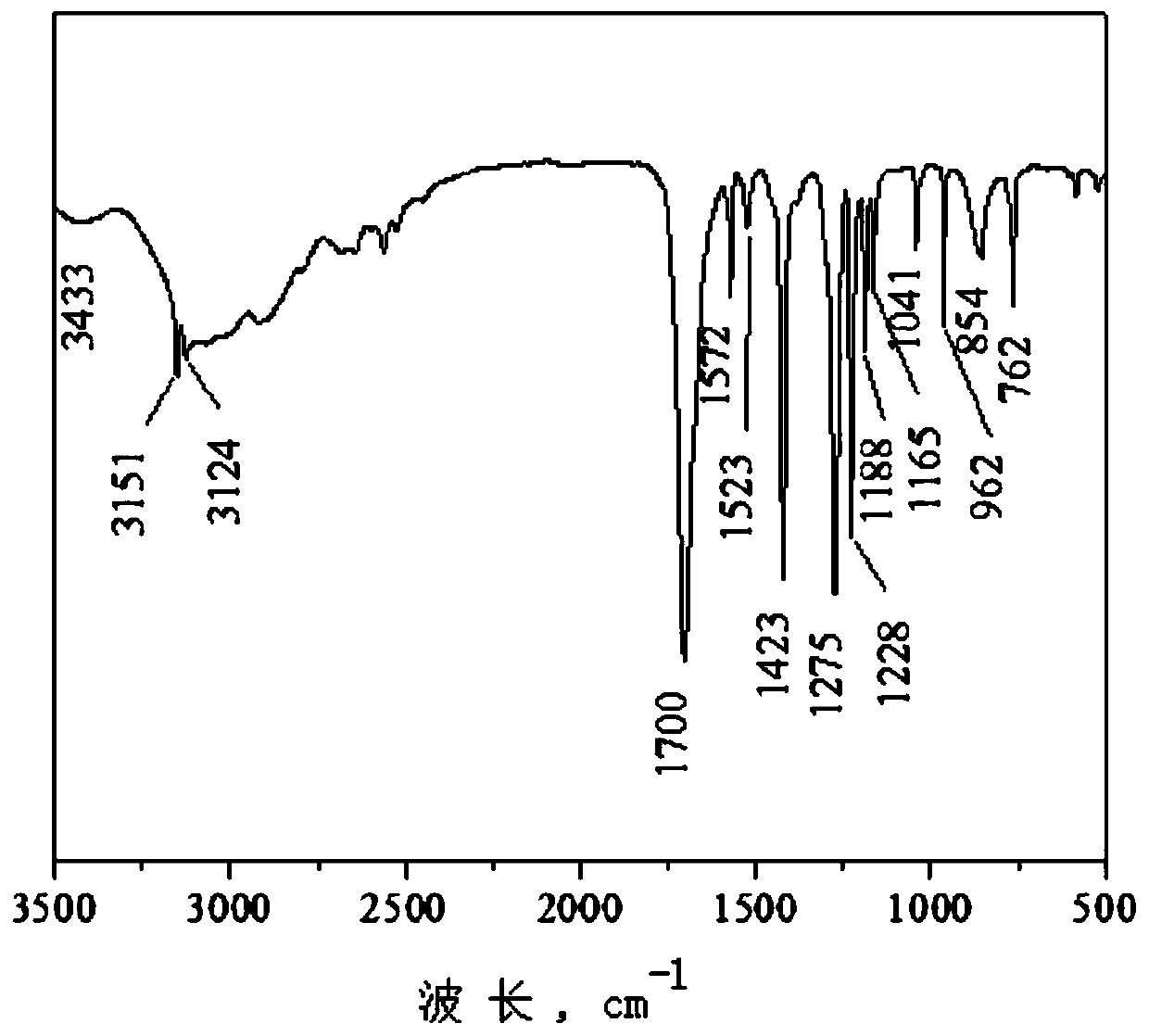

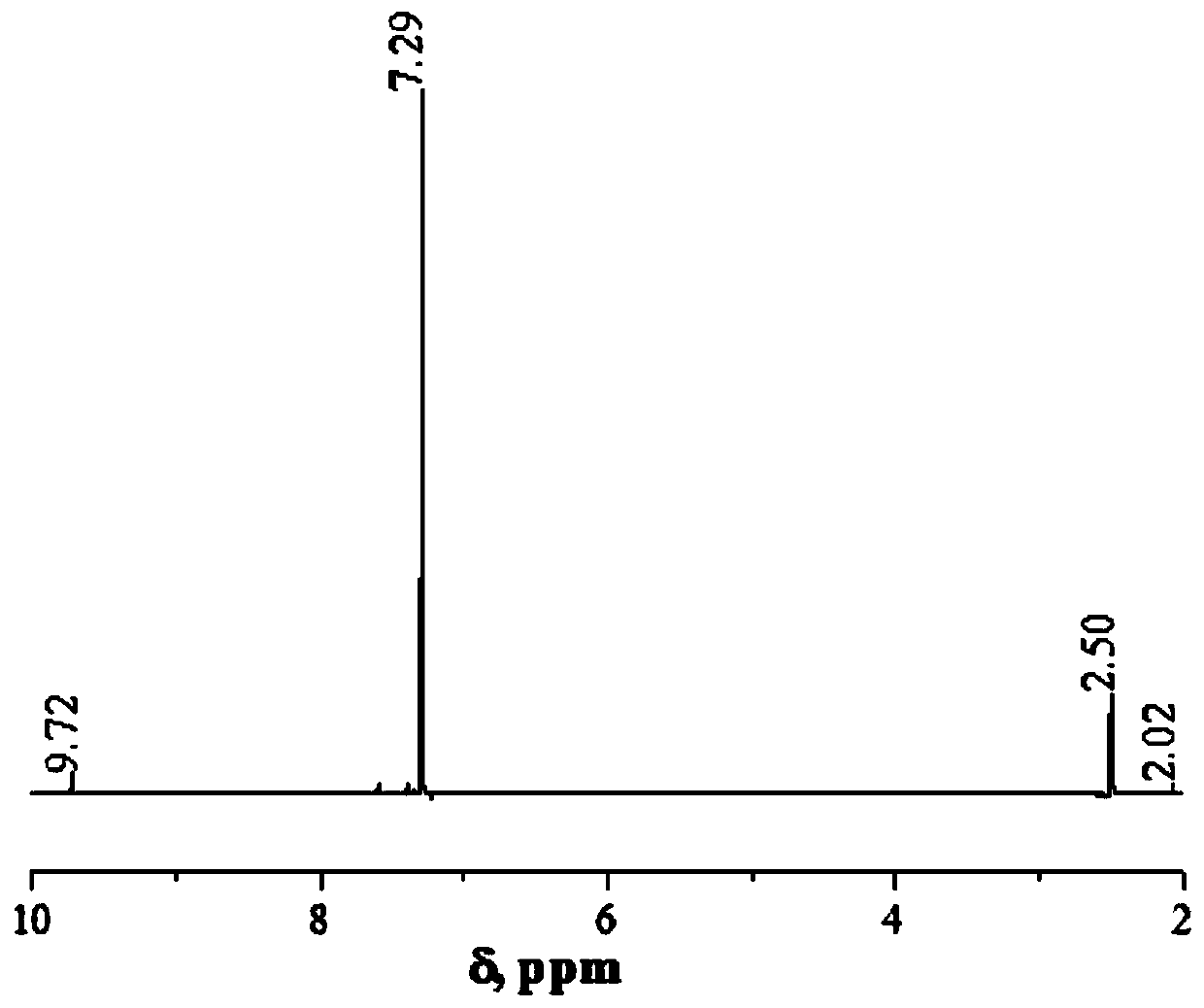

Embodiment 1

[0054] Place the round bottom flask in a constant temperature magnetic stirring water bath, weigh 1mmol of HMF and 15mmol of potassium ferrate into the round bottom flask, measure 10mL of deionized water into the beaker, stir evenly, and weigh a certain amount of NaOH , so that the molar concentration in the reaction system is 1.6mol / L, weigh a certain amount of K 2 HPO 4 , so that the molar concentration in the reaction system is 0.4mol / L. After reacting at 25°C for 15 minutes, the solution is in the form of slurry. The slurry is filtered to obtain the filtrate, and concentrated hydrochloric acid is added dropwise to the filtrate until there is a large amount of white Precipitation was formed, the obtained turbid solution was filtered, and the substance was baked in an oven at 50° C. for 24 hours to obtain a dry white product FDCA with a yield of 86.1%.

Embodiment 2

[0056] Place the round bottom flask in a constant temperature magnetic stirring water bath, weigh 1mmol of HMF and 15mmol of potassium ferrate into the round bottom flask, measure 10mL of deionized water into the beaker, stir evenly, and weigh a certain amount of NaOH , so that the molar concentration in the reaction system is 1.6mol / L, weigh a certain amount of K 2 HPO 4 , so that the molar concentration in the reaction system is 0.4mol / L, weigh a certain amount of Fe(OH) 3 cocatalyst so that its molar concentration in the reaction system is 0.001mol / L; after reacting at 25°C for 15 minutes, the solution is in the form of a slurry, and the slurry is filtered to obtain a filtrate, and concentrated hydrochloric acid is added dropwise to the filtrate until A large amount of white precipitate was formed, and the obtained turbid solution was filtered, and the material was dried in an oven at 50° C. for 24 hours, and the yield of the dry white product FDCA was 91.7%.

Embodiment 3

[0058] Place the round bottom flask in a constant temperature magnetic stirring water bath, weigh 1mmol of HMF and 15mmol of potassium ferrate into the round bottom flask, measure 10mL of deionized water into the beaker, stir evenly, and weigh a certain amount of NaOH , so that the molar concentration in the reaction system is 1.6mol / L, weigh a certain amount of K 2 HPO 4 , so that the molar concentration in the reaction system is 0.4mol / L, weigh a certain amount of MnO 2 Cocatalyst, so that the molar concentration in the reaction system is 0.001mol / L. After reacting at 25°C for 15 minutes, the solution is in the form of slurry. The slurry is filtered to obtain the filtrate, and concentrated hydrochloric acid is added dropwise to the filtrate until there is a large amount of A white precipitate was formed, and the obtained turbid solution was filtered, and the substance was dried in an oven at 50° C. for 24 hours, and the yield of the dry white product FDCA was 88.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com