High heat conductivity orientated arrangement interface material and preparation method thereof

An interface material and directional arrangement technology, which is applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of difficult directional arrangement of thermally conductive fillers, and achieve the effect of satisfying market demand, simple preparation method and improving thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment provides a method for preparing an aligned high thermal conductivity interface material, which includes the following steps:

[0035] (1) Premixing: Take 200g of carbon fiber, 300g of spherical alumina powder, 600g of vinyl silicone oil, 400g of hydrogen-containing silicone oil, 10g of platinum catalyst, and 10g of ethynyl cyclohexanol inhibitor into a vacuum mixer, and stir for 10 minutes to form a thermally conductive interface material Raw material 1;

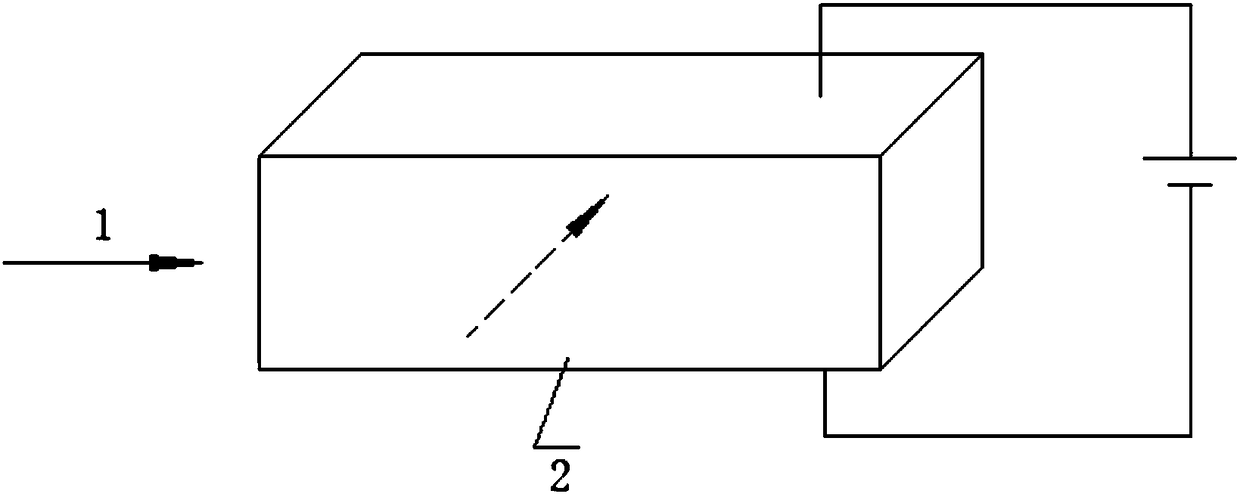

[0036] (2) Injection: see figure 1 , put the above thermal interface material raw material 1 in the injection device, the injection device is connected to a rectangular insulating pipe 2 with a length of 3000 mm, a width of 20 mm, and a thickness of 3 mm, and the injection speed of the thermal interface material raw material 1 is 0.5 m / s (the injection direction is along the figure 1 The direction of the solid arrow in the center, horizontally to the right);

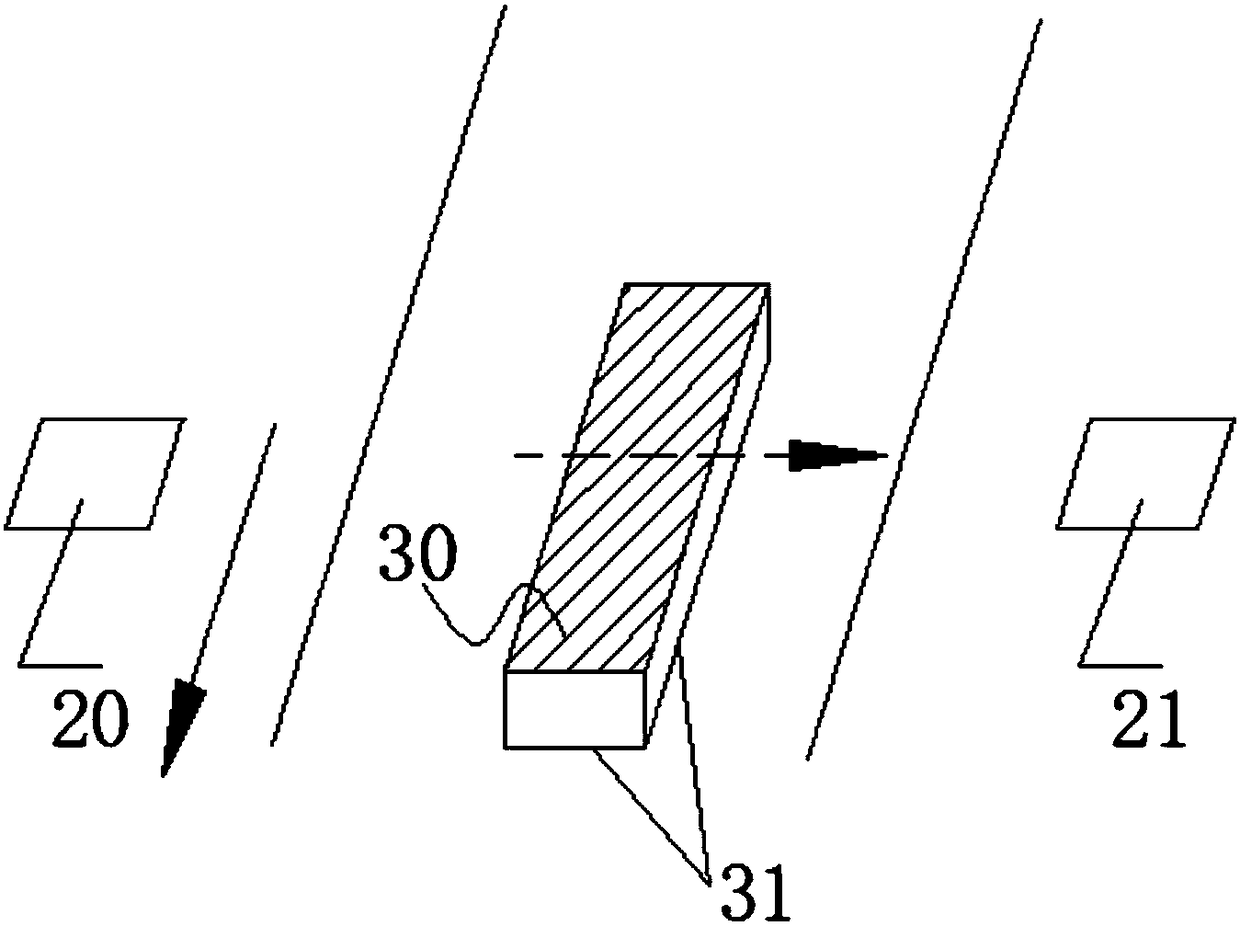

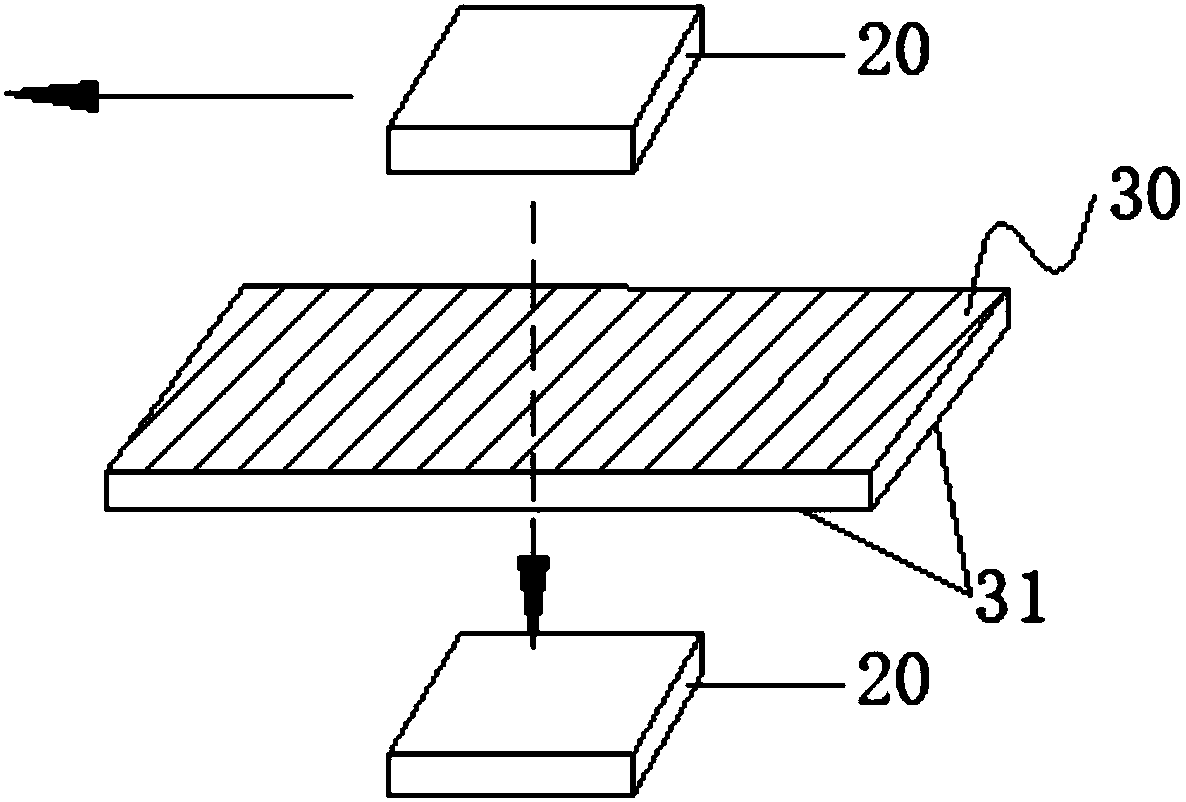

[0037] (3) Directional arrangement: the ...

Embodiment 2

[0040] This embodiment provides a method for preparing an aligned high thermal conductivity interface material, which includes the following steps:

[0041] (1) Premixing: Take 200g of carbon fiber, 300g of spherical alumina powder, 600g of vinyl silicone oil, 400g of hydrogen-containing silicone oil, 10g of platinum catalyst, and 10g of ethynyl cyclohexanol inhibitor into a vacuum mixer, and stir for 10 minutes to form a thermally conductive interface material raw material;

[0042](2) Injection: Place the above-mentioned thermal interface material raw material in the injection device, the injection device is connected to a rectangular insulating pipe with a length of 3000mm, a width of 20mm, and a thickness of 3mm, and the injection speed of the thermal interface material raw material is 0.5m / s;

[0043] (3) Directional arrangement: the copper plate on the lower surface of the rectangular insulated pipe is connected to a positive high voltage of 0.09kV, and the copper plate ...

Embodiment 3

[0045] This embodiment provides a method for preparing an aligned high thermal conductivity interface material, which includes the following steps:

[0046] (1) Premixing: Take 200g of graphene, 300g of spherical alumina powder, 600g of vinyl silicone oil, 400g of hydrogen-containing silicone oil, 10g of platinum catalyst, and 10g of ethynyl cyclohexanol inhibitor into a vacuum mixer, and stir for 10 minutes to form a thermal interface raw materials;

[0047] (2) Injection: Place the above-mentioned thermal interface material raw material in the injection device, the injection device is connected to a rectangular insulating pipe with a length of 3000mm, a width of 20mm, and a thickness of 3mm, and the injection speed of the thermal interface material raw material 1 is 0.5m / s;

[0048] (3) Directional arrangement: the copper plate on the lower surface of the rectangular insulated pipe is connected to a positive high voltage of 0.09kV, and the copper plate on the upper surface i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com