Efficient separation method for arsenic and alkali in arsenic alkali residues

A separation method and technology of arsenic-alkali slag, which is applied in the treatment of arsenic-alkali slag and the efficient separation of arsenic and alkali in arsenic-alkali slag, can solve the problems of low efficiency, high cost, and incomplete separation of arsenic-alkali slag, and achieve the separation effect Good, easy to operate, and the effect of improving the value of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

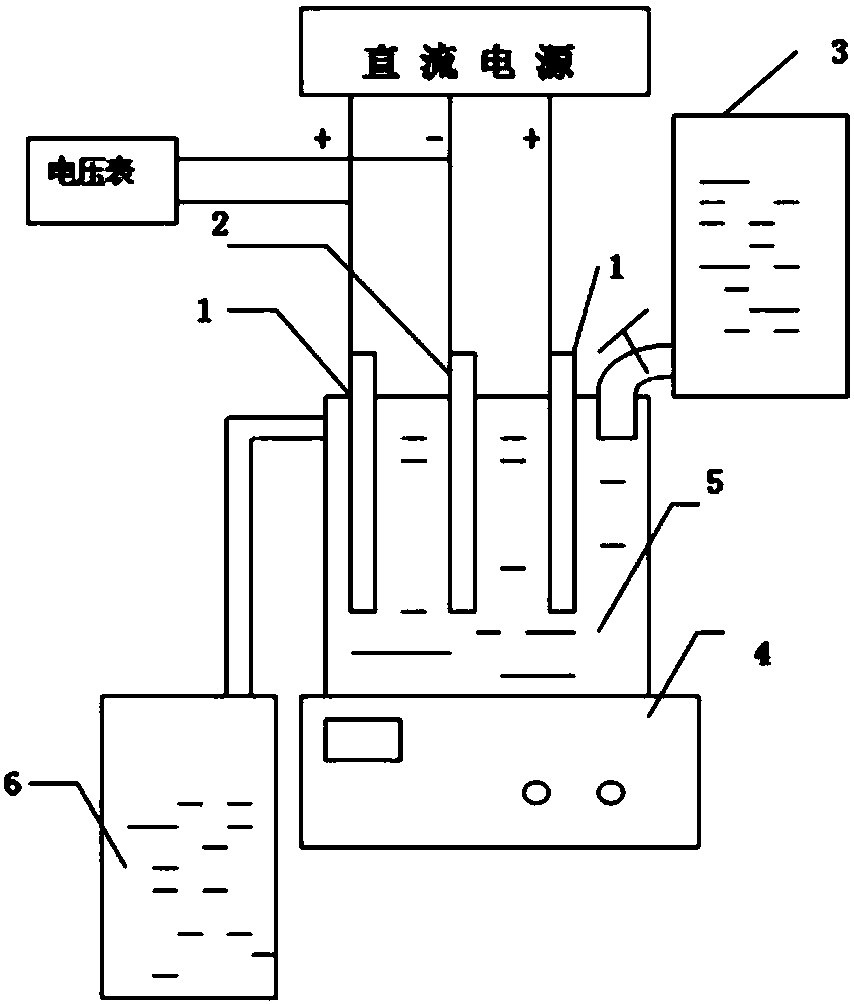

Image

Examples

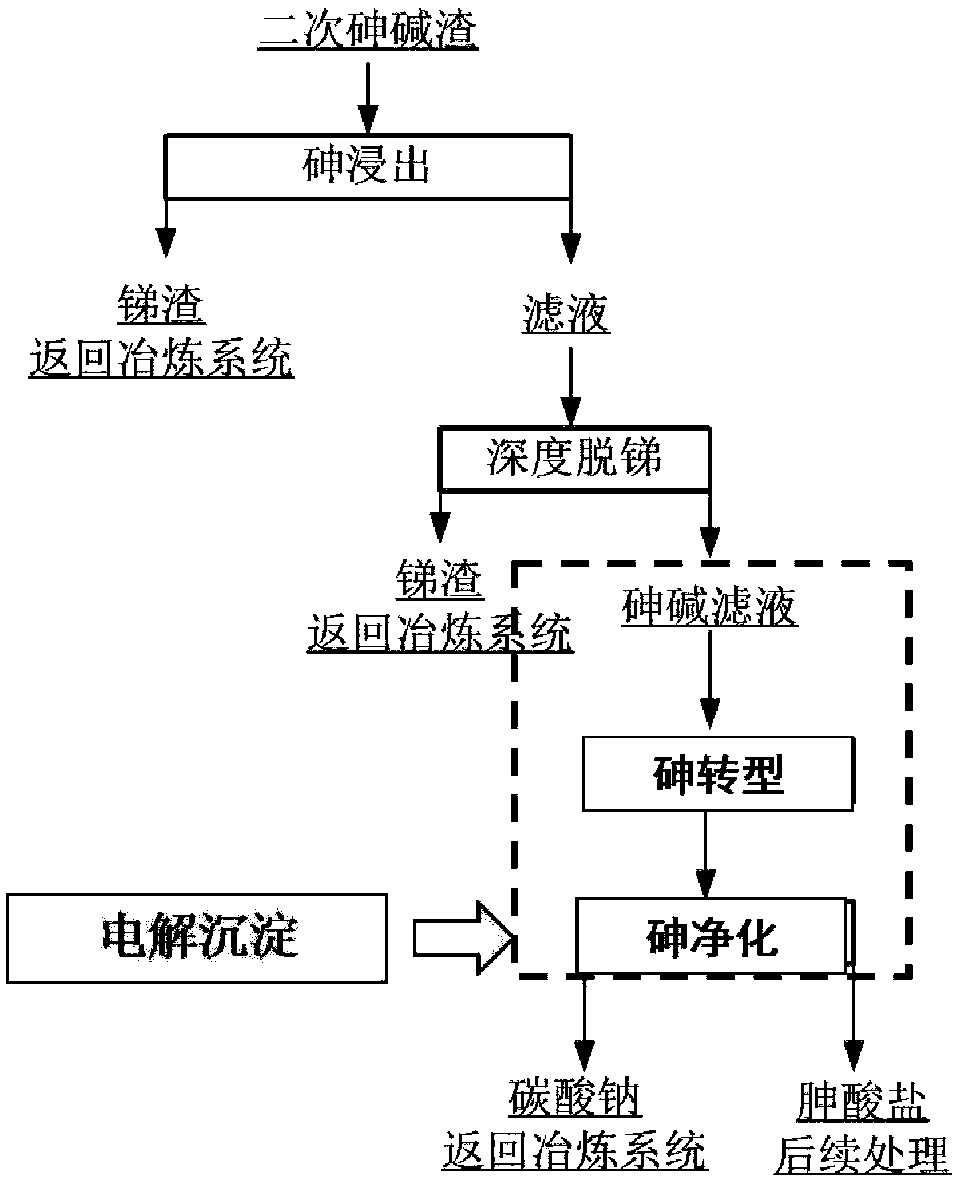

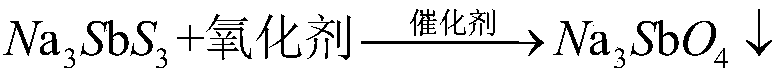

Embodiment 1

[0047] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content of the polluted acid is as high as 9.78g / L, the Sb content is 5.42g / L, and the sodium carbonate content is 41.34g / L. Take 50g of arsenic-alkali slag, grind it for 10 minutes, and ensure that -200 mesh accounts for 82%, add 250ml of water, stir at high speed, leaching temperature is 80°C, leaching time is 60 minutes, and the filtrate obtained by filtering is sodium carbonate, sodium arsenate and antimonous acid The mixed solution of sodium and the leaching slag are returned to the antimony smelting system. Add 0.04g ultra-fine pyrrhotite catalyst to the filtrate, then add hydrogen peroxide with a concentration of 30%, react for 30 minutes, magnetic separation (magnetic field strength 800GS) separate pyrrhotite and recycle it, and filter the non-magnetic component to obtain arsenic Sodium acid solution, sodium antimonate is returned to the antimony smelting system...

Embodiment 2

[0052] Using this process to treat the secondary arsenic-alkali slag of an antimony smelter in Hunan, the As content of the polluted acid is as high as 11.28g / L, the Sb content is 3.12g / L, and the sodium carbonate content is 26.61g / L. Take 50g of arsenic-alkali slag, grind it for 10 minutes, and ensure that -200 mesh accounts for 86%, add 250ml of water, stir at high speed, the leaching temperature is 85°C, and the leaching time is 60 minutes. The filtrate obtained by filtering is sodium carbonate, sodium arsenate and antimonous acid. The mixed solution of sodium and the leaching slag are returned to the antimony smelting system. Add 0.06g superfine pyrrhotite catalyst to the filtrate, then add sodium hypochlorite, react for 25min, magnetic separation (magnetic field strength 1000GS) separate pyrrhotite and recycle, non-magnetic component filtration is sodium arsenate solution, Sodium antimonate is returned to the antimony smelting system. Heat the filtrate to 90°C, add 80mg / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com