Underground laser detection device

A laser detection, buried technology, applied in the field of detection, can solve the problems such as the upper limit of the number of times/cycle, complicated maintenance, no judgment, etc., to achieve the effect of anti-interference, no false alarm, strong anti-interference, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

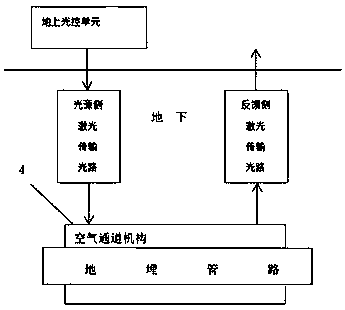

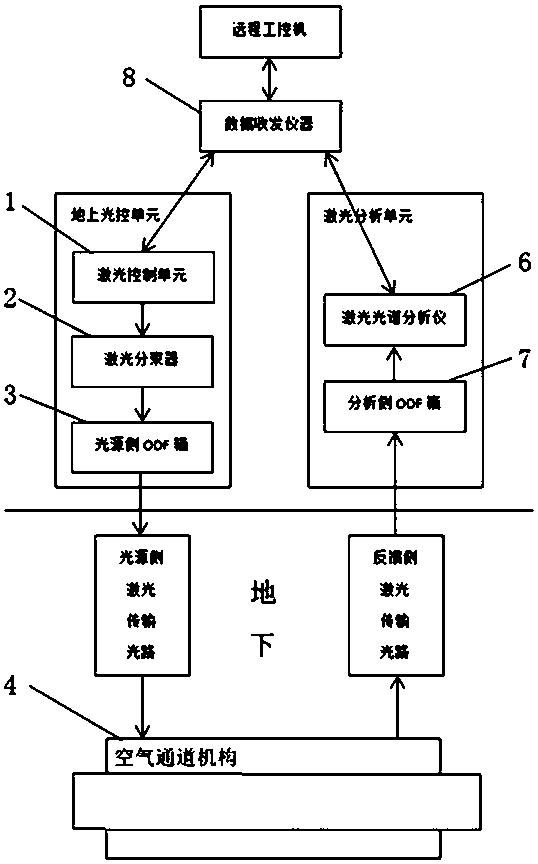

[0032] The structural features of the present invention will now be described in detail in conjunction with the accompanying drawings.

[0033] combine figure 1 , 2 And 7, an underground laser detection device, which is composed of two parts: an aboveground light control unit and an underground monitoring unit. Among them, the ground light control unit is set in the base station and is responsible for generating laser light. The underground monitoring unit is buried underground, and is responsible for transmitting the laser beam generated by the above-ground light control unit to the detection area, and transmitting the laser beam back to the ground.

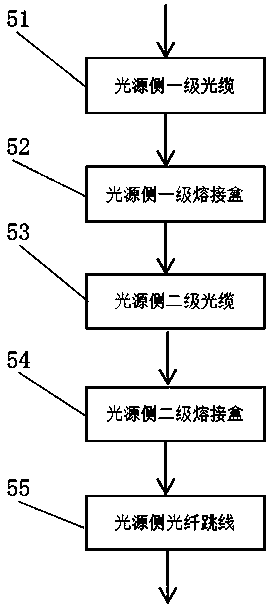

[0034] see figure 2 Or 7, further speaking, the ground optical control unit includes a laser control unit 1 , a laser beam splitter 2 , and an ODF (Optical Distribution Frame, optical fiber distribution frame) box 3 on the light source side. Wherein, the laser control unit 1 is connected with the ODF box 3 on the light sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com