Reinforcement corrosion expansion stress monitoring device in concrete

A technology of stress monitoring and monitoring devices, which is applied in measuring devices, electromagnetic measuring devices, measuring force, etc., can solve the problems of increased workload, poor efficiency, and high cost, and achieve the effects of low cost, reliable testing, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

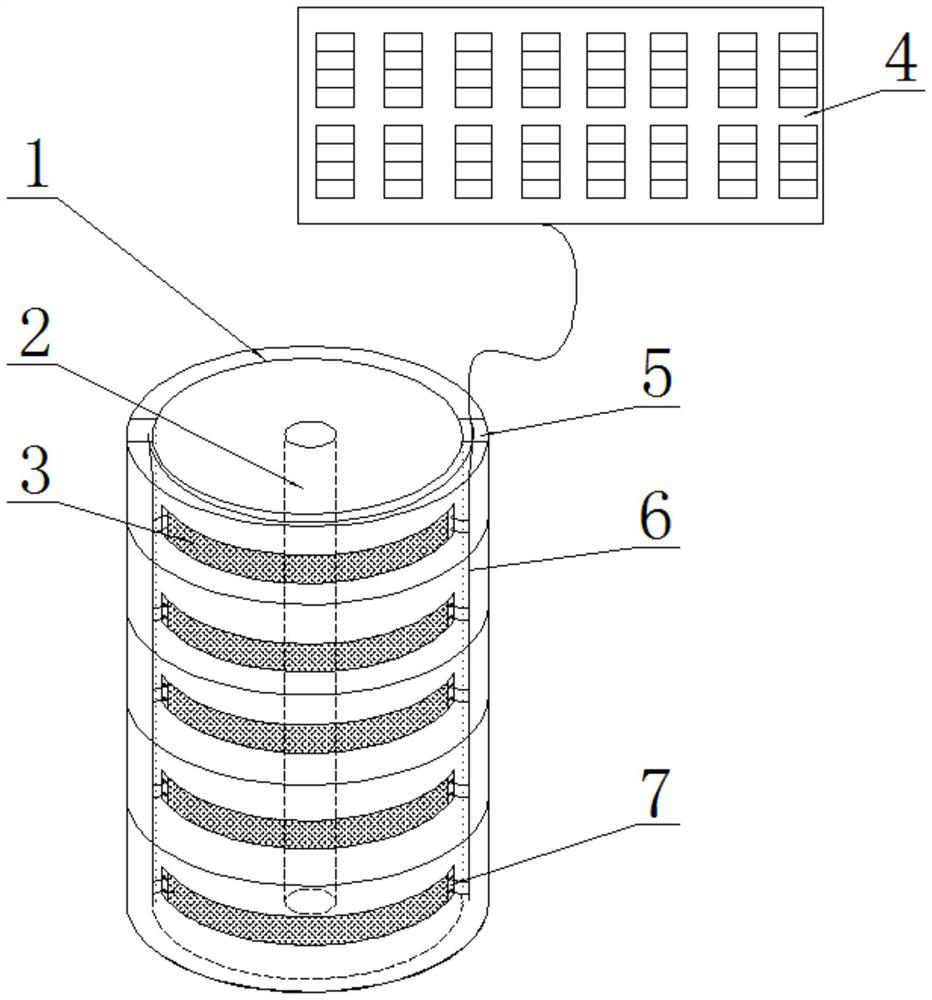

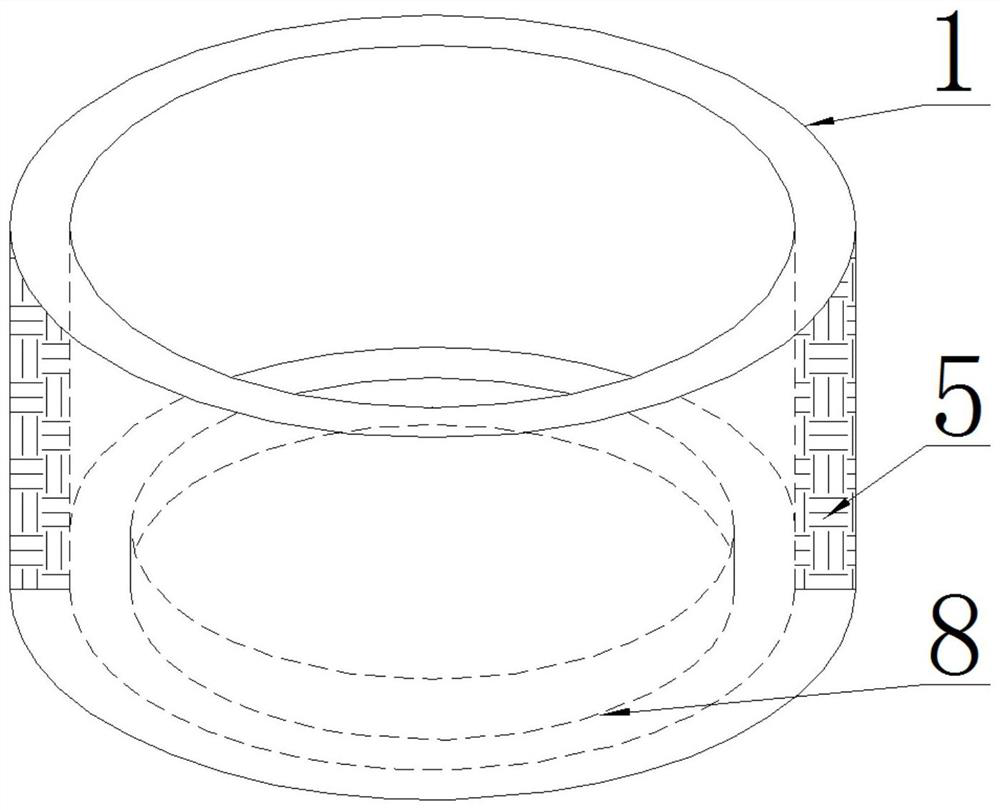

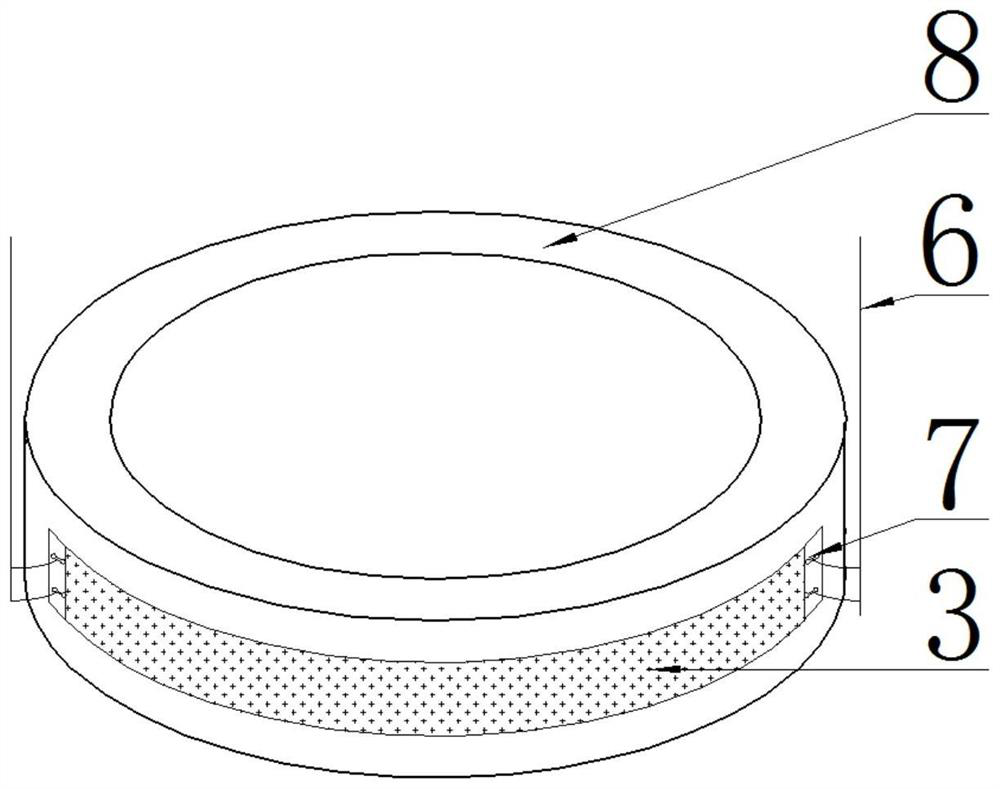

[0034] Such as Figure 1 to Figure 5 As shown, the inner radius of the thick-wall support 1 is 42mm, the height is 7mm, and the wall thickness is 4mm. The circular column is made of 304 stainless steel, and its outer radius is 40mm, the height is 7mm, the wall thickness is 4mm, and the radius of the platform 8 is 36mm. , the height is 3mm, the wall thickness is 10mm, the length of the foil resistance strain gauge 3 is 55mm, and the width is 4.5mm. Glue-based terminals 7 are bonded to the ends, and insulated wires 6 are connected. Put the stainless steel ring column on the bearing platform 8, the bottom of the ring column and the surface of the bearing platform 8 are bonded with an adhesive, and the gap between the stainless steel ring column and the thick-walled support 1 is sealed with a waterproof sealant. Prevent the concrete from flowing into the gap when the concrete is poured, and the second is to avoid the internal pressure of the external PVC pipe on the resistance st...

Embodiment 2

[0037] The inner radius of the stainless steel ring column is 40mm, the wall thickness is 4mm, the height is 50mm, the tensile strength is ≥ 520MPa, and the diameter of the threaded steel bar is 10mm or 14mm. Mix C50 concrete with seawater, remove the base after 28 days of maintenance, and use the constant voltage method of external power supply to accelerate the corrosion of threaded steel bars. The voltage is 30V, and the current range is 0-5A. The method of connecting with the stabilized DC power supply accelerates the corrosion of threaded steel bars in concrete, and adopts the strain acquisition instrument 4 to collect real-time strain values, and the results are as follows Figure 7 shown.

[0038] Use the electrical acceleration method to accelerate the corrosion of threaded steel bars. When the rust spots accumulate to a certain extent, expansion stress will be generated on the mortar, causing the mortar to expand and deform. Once the mortar is deformed, the expansion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com