Wollastonite fiber plastic master batch and preparation method

A wollastonite fiber and plastic masterbatch technology, which is applied in the field of plastic masterbatch, can solve the problems of difficult dispersion, low interface bonding strength, poor dimensional stability, etc., to improve dispersion and stability, improve compatibility, The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

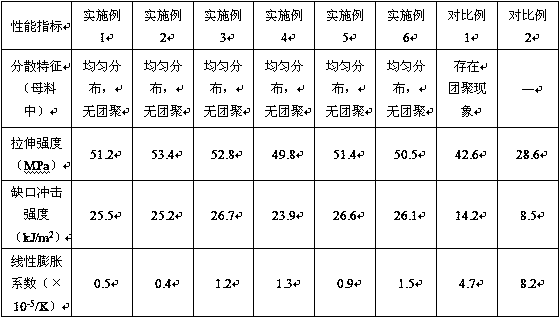

Examples

Embodiment 1

[0031] The preparation process is:

[0032] (1) Calcinate the wollastonite fiber at 850°C at a high temperature, add a solution containing a surfactant after cooling, and completely immerse the wollastonite fiber in the solution of the surfactant, then filter it with suction and dry it. Pretreated wollastonite fiber; wollastonite fiber is powder obtained by crushing low temperature triclinic wollastonite; surfactant is alkyl glucoside;

[0033] (2) Add 38 parts by weight of the pretreated wollastonite fiber prepared in step (1) into 56 parts by weight of acetone, and disperse evenly by ultrasonic, then add 6 parts by weight of carboxymethyl chitosan, mix and stir and transfer to a ball mill , Grind for 1.5h at a rotating speed of 45r / min to obtain wollastonite fibers modified by carboxymethyl chitosan; the ultrasonic frequency of ultrasonic dispersion is 27kHz, and the time is 25min; the ball mill is a horizontal ball mill;

[0034](3) Add 85 parts by weight of the modified w...

Embodiment 2

[0044] The preparation process is:

[0045] (1) Calcinate the wollastonite fiber at 800°C at a high temperature, add a solution containing a surfactant after cooling, and completely immerse the wollastonite fiber in the solution of the surfactant, then suction filter and dry to obtain the processed Pretreated wollastonite fiber; the wollastonite fiber is the powder obtained by pulverizing parawollastonite; the surfactant is fatty acid glyceride;

[0046] (2) Add 35 parts by weight of the pretreated wollastonite fiber prepared in step (1) into 60 parts by weight of acetone, and disperse evenly by ultrasonic, then add 5 parts by weight of carboxymethyl chitosan, mix and stir and transfer to a ball mill , Grind for 2h at a rotating speed of 40r / min to obtain wollastonite fibers modified by carboxymethyl chitosan; the ultrasonic frequency of ultrasonic dispersion is 25kHz, and the time is 30min; the ball mill is a roller ball mill;

[0047] (3) Add 80 parts by weight of the modif...

Embodiment 3

[0057] The preparation process is:

[0058] (1) Calcinate the wollastonite fiber at 900°C at high temperature, add a solution containing a surfactant after cooling, so that the solution of the surfactant is completely immersed in the wollastonite fiber, and then filter and dry to obtain the processed Pretreated wollastonite fiber; the wollastonite fiber is powder obtained by pulverizing pseudo wollastonite; the surfactant is sorbitan fatty acid;

[0059] (2) Add 40 parts by weight of the pretreated wollastonite fiber prepared in step (1) into 52 parts by weight of acetone, and disperse evenly by ultrasonic, then add 8 parts by weight of carboxymethyl chitosan, mix and stir and transfer to a ball mill , Grind for 1 hour at a rotating speed of 50r / min to obtain wollastonite fibers modified by carboxymethyl chitosan; the ultrasonic frequency of ultrasonic dispersion is 30kHz, and the time is 20min; the ball mill is a vibrating ball mill;

[0060] (3) Add 90 parts by weight of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com