A radiation-resistant, strong-acid-resistant, dual-curing heavy-duty anti-corrosion coating

A dual-curing, strong-acid-resistant technology, applied in the direction of anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of poor strong acid resistance of the paint film, large curing shrinkage, and high brittleness of the paint film, and achieve stable performance and anti-corrosion. The effect of strong medium permeability and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of a radiation-resistant, strong acid-resistant, double-cured heavy-duty anti-corrosion coating of the present invention, the steps are as follows:

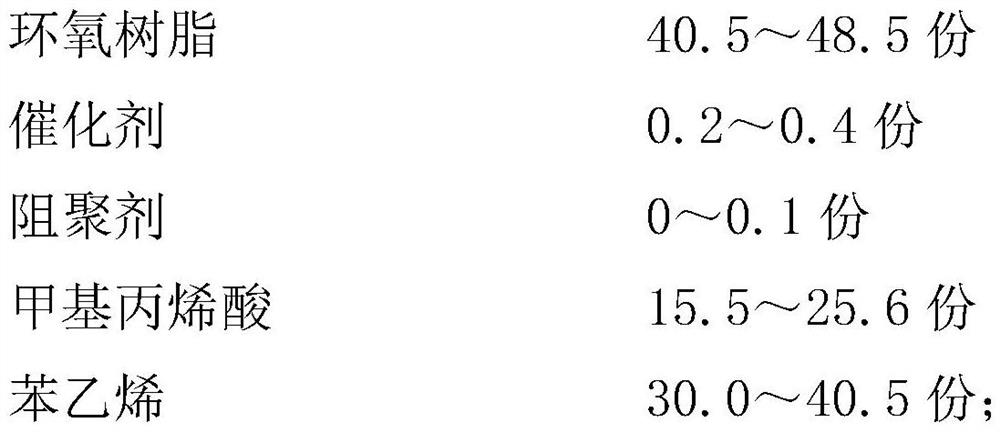

[0030] (1) Add 46.6kg of epoxy resin, 0.3kg of catalyst and 0.06kg of polymerization inhibitor into the reaction kettle, stir and dissolve, add 17.7kg of methacrylic acid to 80°C, heat up to 110-130°C, and keep warm until the acid value When the appropriate value is reached, cool down to 80°C and add 34.8kg of styrene dilute, stir well to obtain vinyl ester resin;

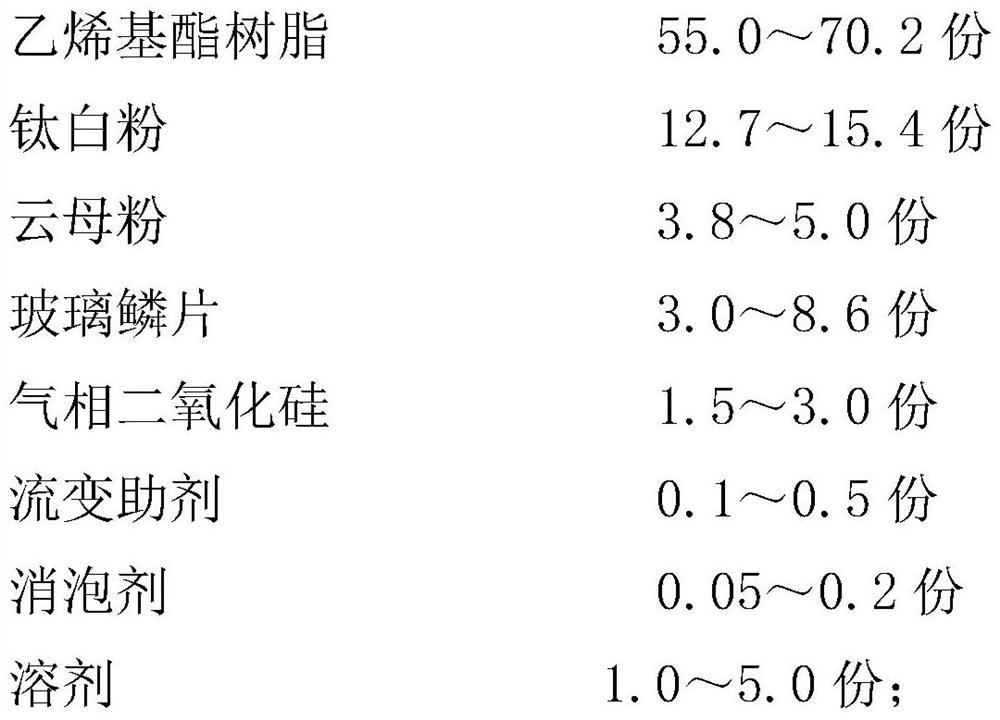

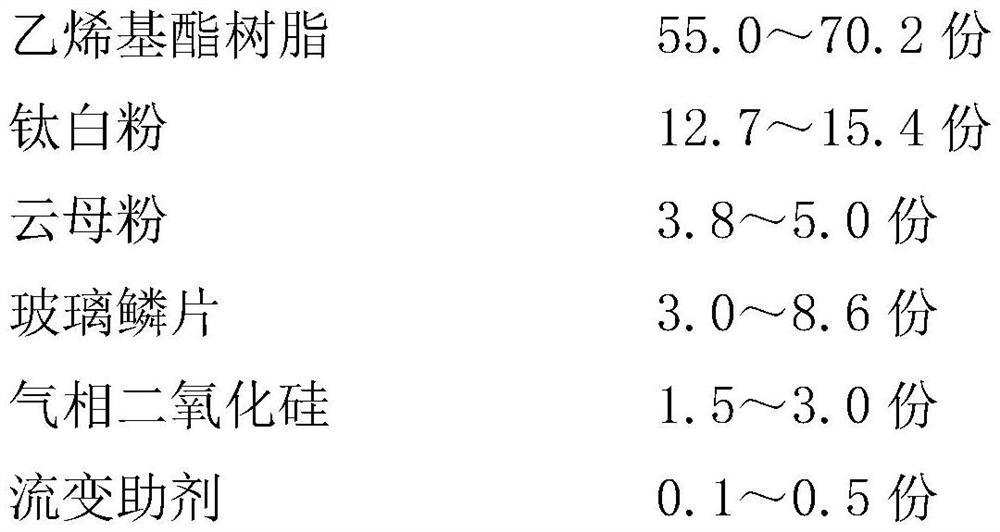

[0031] (2) Add 57.5kg of vinyl ester resin, 12.7kg of titanium dioxide, 3.8kg of mica powder, 2.4kg of fumed silica and 4.7kg of styrene into an enamel tank and stir at high speed, disperse evenly, and grind to fineness on a conical mill Below 30μm, add 0.3kg of rheological additives, 0.17kg of defoamer, while stirring, add 7kg of glass flakes and stir until evenly dispersed to obtain component A;

[0032] (3) Add 3kg of initiator and 2k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com