Novel decorative material and manufacturing method thereof

A manufacturing method and technology for decorative materials, applied in the field of decorative materials, can solve the problems of single color of decorative materials shielding electrical signals, etc., and achieve the effects of not easy to decolorize, uniform color, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The glass fiber cloth 7628 of this embodiment.

[0029] The steps of a manufacturing method of a colored fiberglass ornament are as follows:

[0030] First, place the glass fiber in a BH furnace with a temperature of about 400°C for 1 hour to remove the drawing sizing agent coated on the surface of the glass fiber during the original drawing process and remove the coating on the yarn during the sizing process. The coated slurry is then cooled by natural wind to obtain clean glass fibers;

[0031] Then apply a silane coupling agent to the surface of the cleaned glass fiber cloth, the type is γ-(2,3-epoxypropoxy)propyltrimethoxysilane (KH-560 for short);

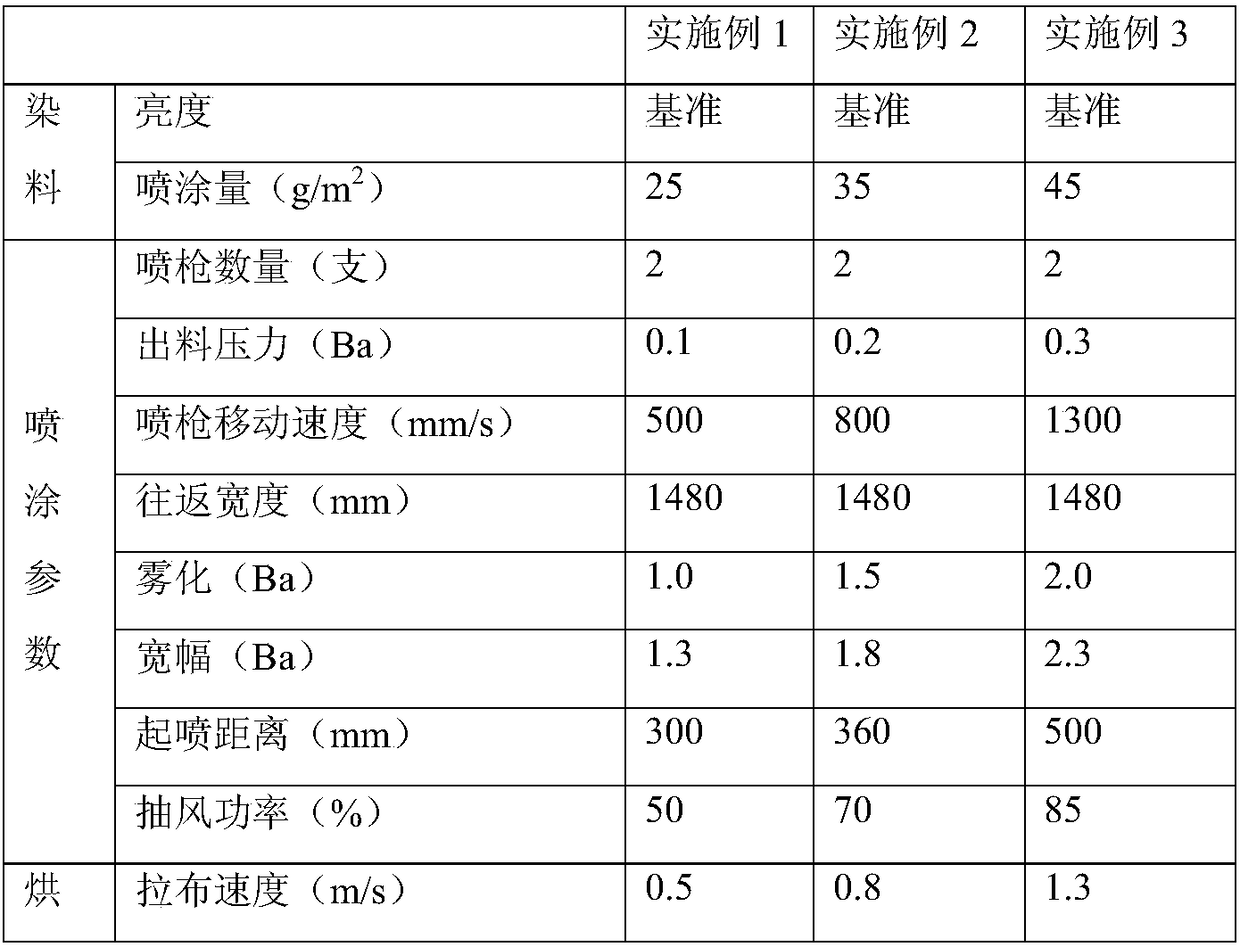

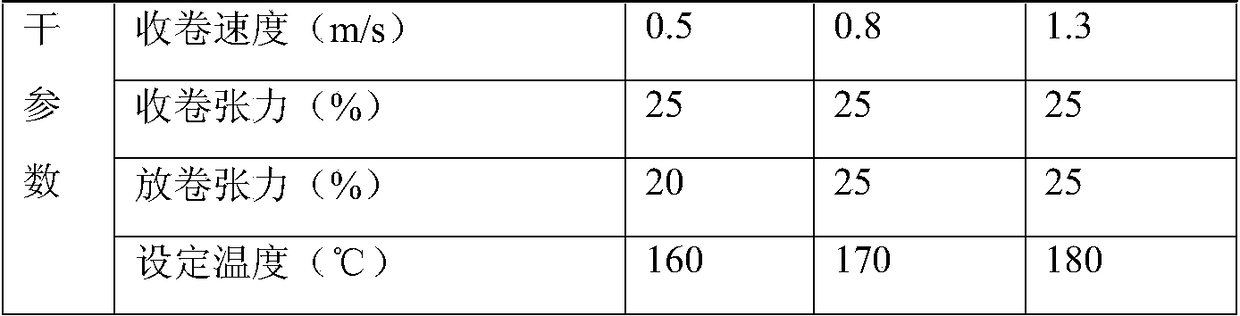

[0032] Finally, the glass fiber after the above-mentioned post-treatment is colored, and the post-treated glass fiber from the unwinding device moves through the coloring device. The coloring device has two spray guns, symmetrically distributed on both sides of the glass fiber cloth, each Each spray gun sprays organic...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 lies in the coloring parameters, see Table 1 for details. The obtained colored fiberglass decoration material is a colored pattern.

Embodiment 3

[0037] The difference between this embodiment and embodiment 1 is that the coloring parameters are different, see Table 1 for details. The result is a colored fiberglass trim material in a single color pattern.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com