Design method for annular structural member diffusion bonding fixture

A technology of diffusion connection and ring structure, which is applied in the direction of welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of insufficient research on diffusion connection, large residual stress, complex process, etc., and achieve uniform and adjustable overall force, Solve the effect of high temperature stress deformation and ensure safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

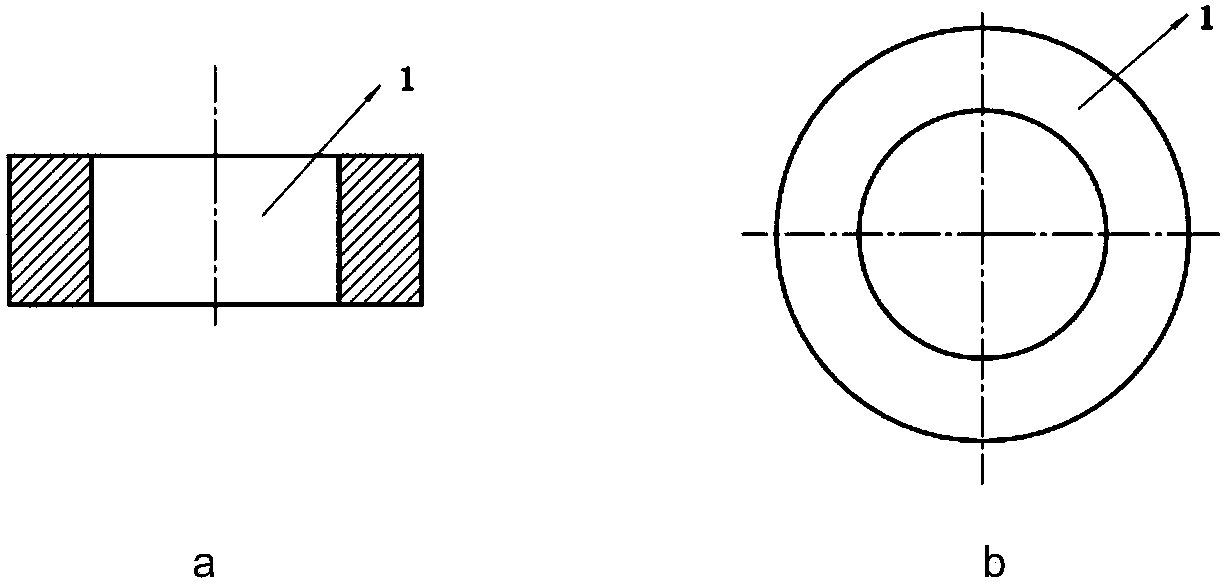

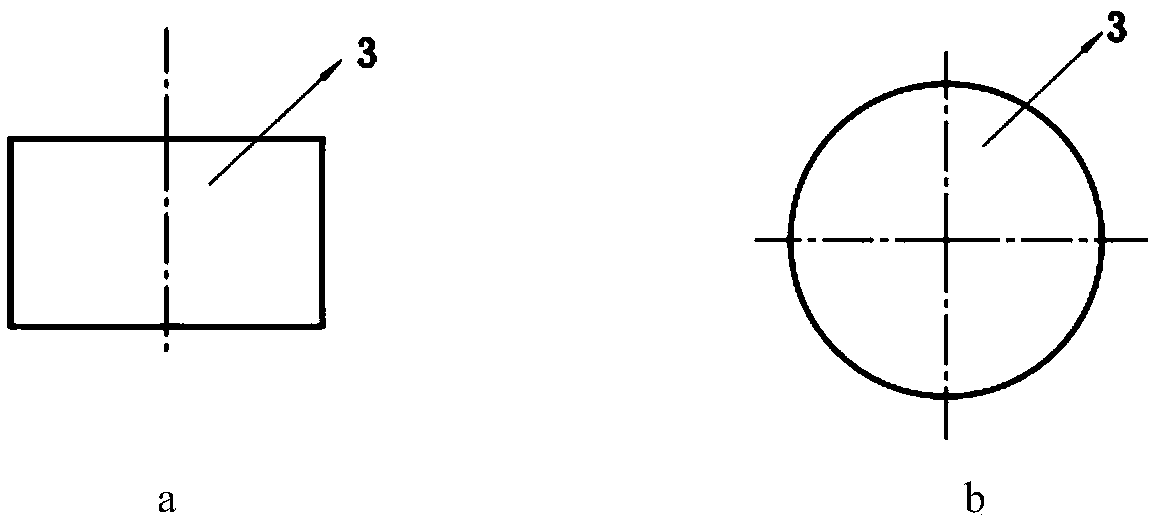

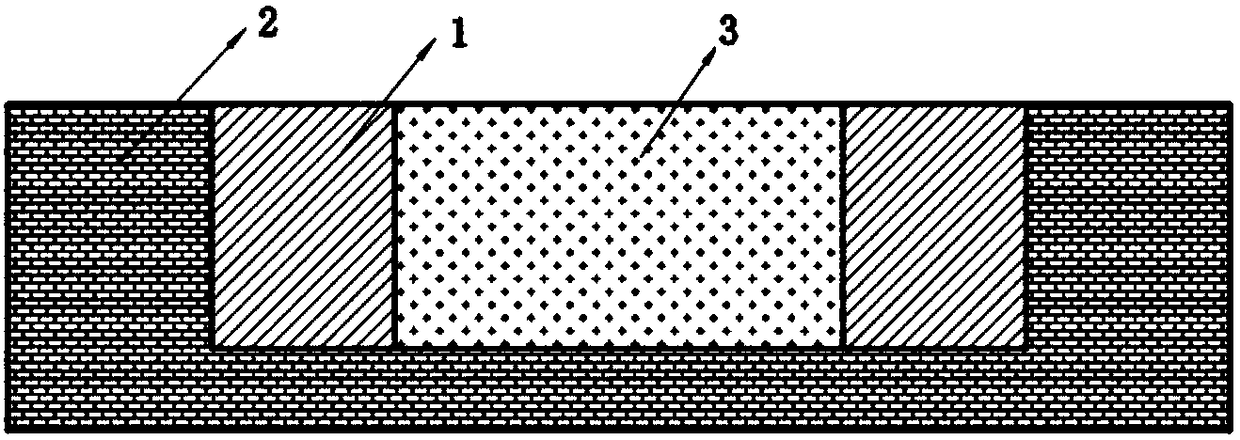

[0041] This embodiment is a method for designing a fixture for the diffusion connection of a ring. Specifically TiAl rim 1 with Ti 2 AlNb disc 3 diffusion bonding fixture design method.

[0042] The TiAl rim is a ring, and its nominal composition is Ti-45Al-8.5Nb-0.2W-0.2B-0.3Y; the Ti 2 The AlNb disc is cylindrical, and its nominal composition is Ti-22Al-25Nb.

[0043] The key to the design of the present invention is that the material for the ring fixture must have strong mechanical properties at high temperature, and the coefficient of thermal expansion should be smaller than the smaller one of the expansion coefficients of the inner and outer layer alloys. The selection of the expansion coefficient of the clamp material should be considered comprehensively with the high temperature mechanical properties of the material, because the smaller the expansion coefficient of the clamp material, the greater the connection pressure and the extrusion force on the clamp itself. Se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com