Preparation method of printable nanocomposite elastic conductor, conductive paste and electronic fabric

A nanocomposite and conductive paste technology, applied in the field of nanomaterials, can solve the problems of difficult to form composites, poor conductivity and poor compatibility of carbon materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a printable nanocomposite elastic conductor, comprising the following steps:

[0041] Under grinding conditions, mixing the ethylene glycol dispersion of the silver nanowires and the dimethylformamide solution of the thermoplastic polyurethane elastomer to obtain a mixed slurry;

[0042] Precipitating flocculent precipitates in the mixed slurry in a coagulation bath to obtain a printable nanocomposite elastic conductor.

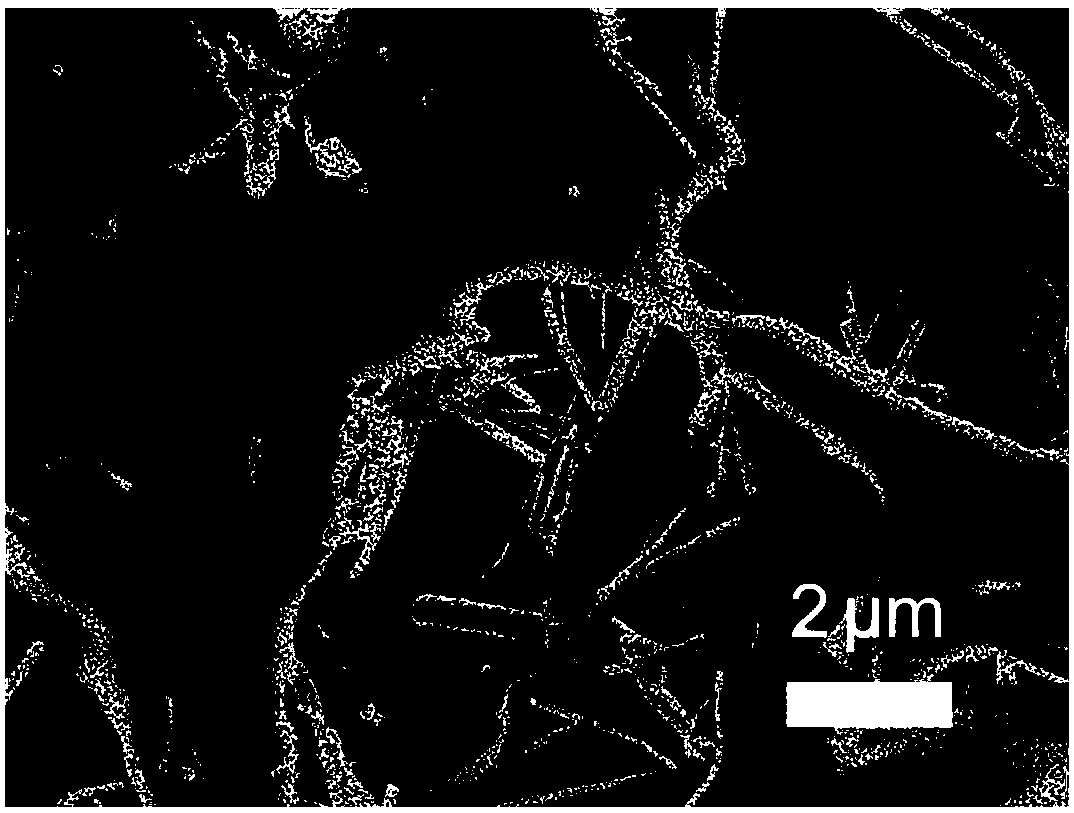

[0043] In the present invention, silver nanowires are used as conductive fillers, thermoplastic polyurethane elastomers are used as elastic substrates, dimethylformamide is used as a solvent, and they are mixed under heating and grinding conditions; then precipitated in a coagulation bath to obtain a printable nanocomposite elastic conductor , as the filling material of the elastic matrix, silver nanowires do not agglomerate and have good dispersion, so that the nanocomposite elastic conductor has good cond...

Embodiment 1

[0092]Settling the silver nanowire dispersion naturally for a week, pouring off the supernatant, leaving only the sediment at the bottom, adding 40mL of ethylene glycol, washing and evenly dispersing, and then centrifuging. , add 20mL ethylene glycol, ultrasonically disperse again, and finally let it stand for a week, remove the lower layer of sediment and add 5mL ethylene glycol, after ultrasonically disperse, the desired silver nanowire ethylene glycol dispersion is obtained, and the silver wire dispersion is quantified to 145mg ·mL -1 .

[0093] Weigh 10g of TPU (Bayer DP9370A) and place it in 20mL of DMF, let it stand for 12h to completely dissolve into a transparent colloid, then take 3g of TPU colloid and put it in a mortar, use a heating plate to heat the mortar to 60°C in advance and keep Maintain a constant temperature, then add 20mL DMF to dilute the TPU colloid to a uniform solution.

[0094] Take 0.5mL silver nanowire ethylene glycol dispersion, slowly add drop b...

Embodiment 2

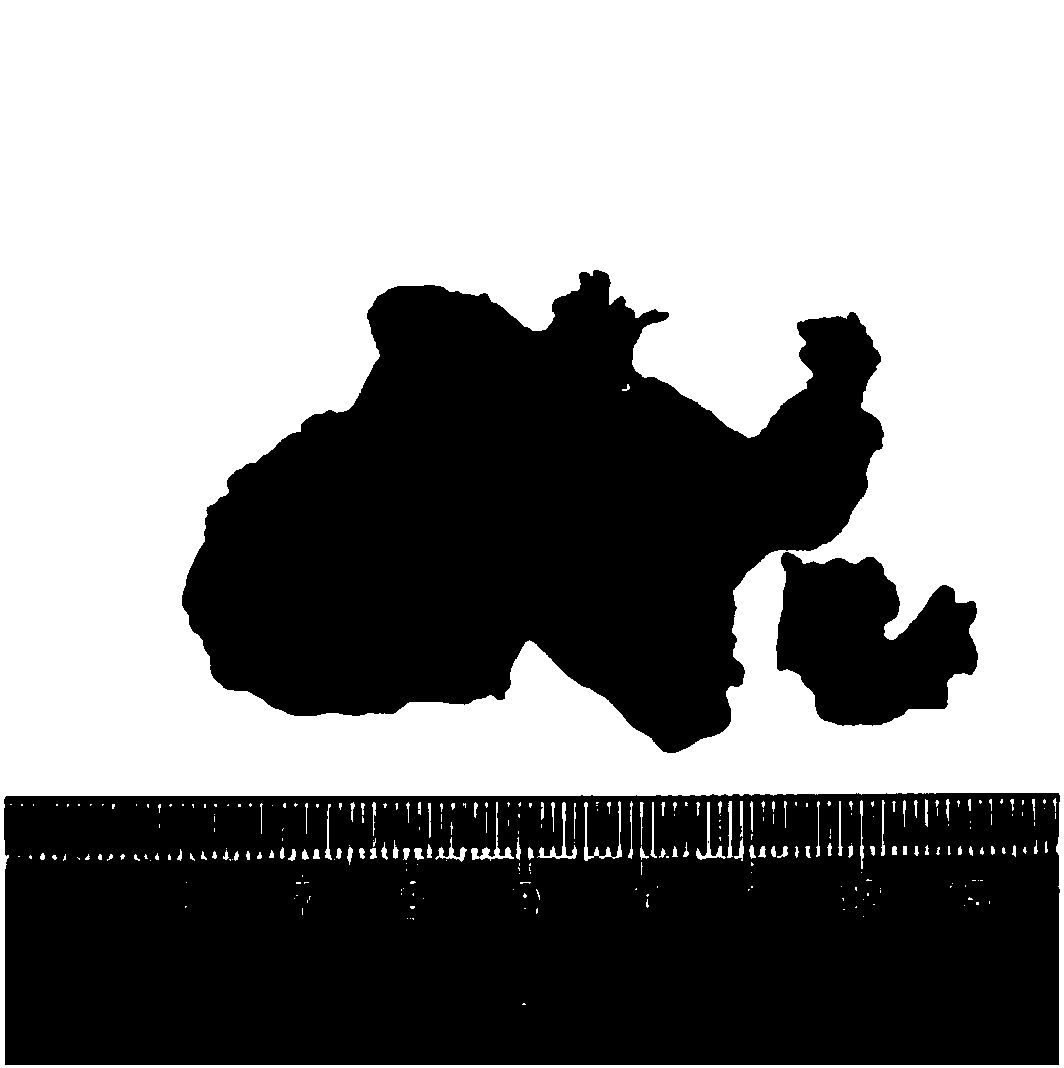

[0106] Put the nanocomposite elastic conductor with a silver nanowire content of 0.91vol% prepared in Example 1 into a mortar, add 5mL of DMF, grind gently at 80°C, and disperse the composite into a uniform slurry, such as Figure 9 as shown, Figure 9 Schematic diagram of the appearance of the slurry configured for Example 2 of the present invention, and then the slurry was diluted to 20mL with DMF;

[0107] Then take 0.5mL of silver nanowire ethylene glycol dispersion, slowly drop it into the TPU solution, stir with a pestle to make the silver wire evenly dispersed in the TPU solution, and obtain a mixed slurry;

[0108] Slowly add the mixed slurry into 200mL of methanol, shake the beaker after adding, and obtain a flocculent composite; wash the flocculent composite repeatedly with water, and dry at 60°C to obtain a nanocomposite with a silver nanowire content of 1.76vol%. material elastic conductor.

[0109] The nanocomposite elastic conductor that embodiment 2 is prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com