Laser packaging OLED illumination panel and packaging method

A laser encapsulation and panel technology, applied in the field of OLED lighting, can solve problems such as the reduction of process yield, and achieve the effects of improving product yield, reducing damage, and reducing glass cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

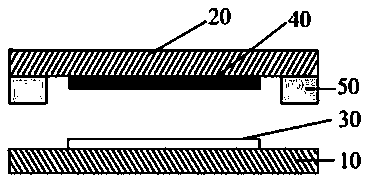

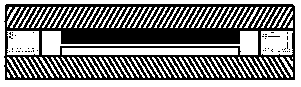

[0039]The laser-encapsulated OLED lighting panel of this embodiment includes a substrate (10) at the bottom, a cover (20) at the top, and a light-emitting device (30) arranged between the substrate (10) and the cover (20). A cooling liquid (40) is also included between the base plate (10) and the cover plate (20), and a seal for sealing the light emitting device (30) and the cooling liquid (40) in the base plate (10) and the cover plate (20) Body (50).

[0040] The substrate (10) is a glass substrate;

[0041] The cover plate (20) is a glass cover plate, the glass cover plate is a groove cover plate, and the groove area corresponds to the position of the cooling liquid, and the groove thickness of the groove cover plate is less than 0.6mm.

[0042] The light emitting device (30) includes a cathode, an anode and a light emitting unit.

[0043] The sealing body (50) is glass frit, and its material is composed of glass powder, oxide filler, adhesive and resin as a carrier.

[...

Embodiment 2

[0054] The product structure of the present embodiment is the same as that of the embodiment. Materials and preparation methods vary.

[0055] The material of the cooling liquid (40) is methyl silicone oil, and further dehydration treatment is carried out before use to ensure that the cooling liquid does not absorb moisture, thereby ensuring the quality of the lighting panel.

[0056] The preparation method of the laser-encapsulated OLED lighting panel of this embodiment includes the following steps:

[0057] S1. The light-emitting device is installed on the substrate by using a coating process. The light-emitting device here includes an anode, a light-emitting unit and a cathode. The coating process uses thermal evaporation coating.

[0058] S2. Using a dispenser to coat the glass frit on the substrate to form a set pattern;

[0059] S3. Use the physical dehydration method to dehydrate the cooling liquid under low vacuum;

[0060] S4. Use a dispenser to coat the cooling li...

Embodiment 3

[0066] The product structure of the present embodiment is the same as that of the embodiment. Materials and preparation methods vary.

[0067] The material of the cooling fluid (40) is fluorosilicone oil, and CaO is added to the fluorosilicone oil. The addition of CaO can make the cooling fluid have an additional drying and water absorption function, which can better ensure that the OLED device will not be damaged by water vapor, thereby The service life of the device is further improved.

[0068] The preparation method of the laser-encapsulated OLED lighting panel of this embodiment includes the following steps:

[0069] S1. The light-emitting device is installed on the substrate by using a coating process. The light-emitting device here includes an anode, a light-emitting unit and a cathode. The coating process uses thermal evaporation coating.

[0070] S2. Using a dispenser to coat the glass frit on the substrate to form a set pattern;

[0071] S3. Add a certain amount o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com