Deep processing method for edible fungi

An edible fungus and greening technology, applied in the fields of application, food preservation, food science, etc., can solve the problems of losing the tissue shape, flavor and color of fresh fungi, reducing the value of nutrition and health care, and not being able to eat directly. Long-lasting, low-oil effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

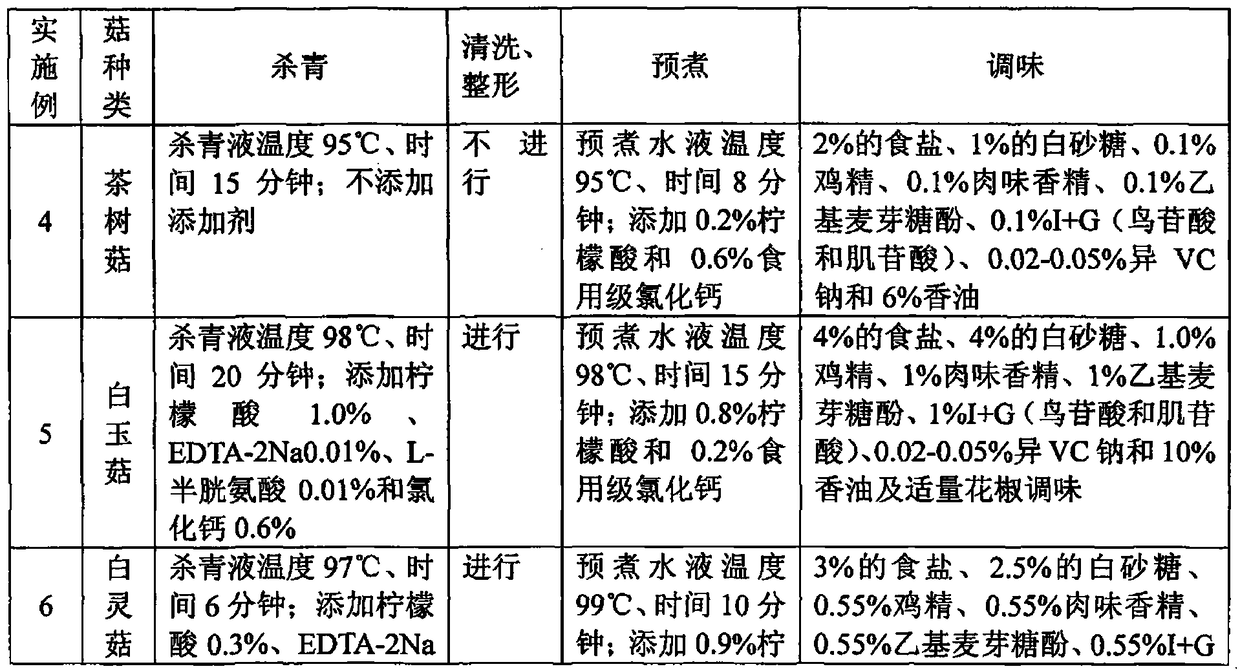

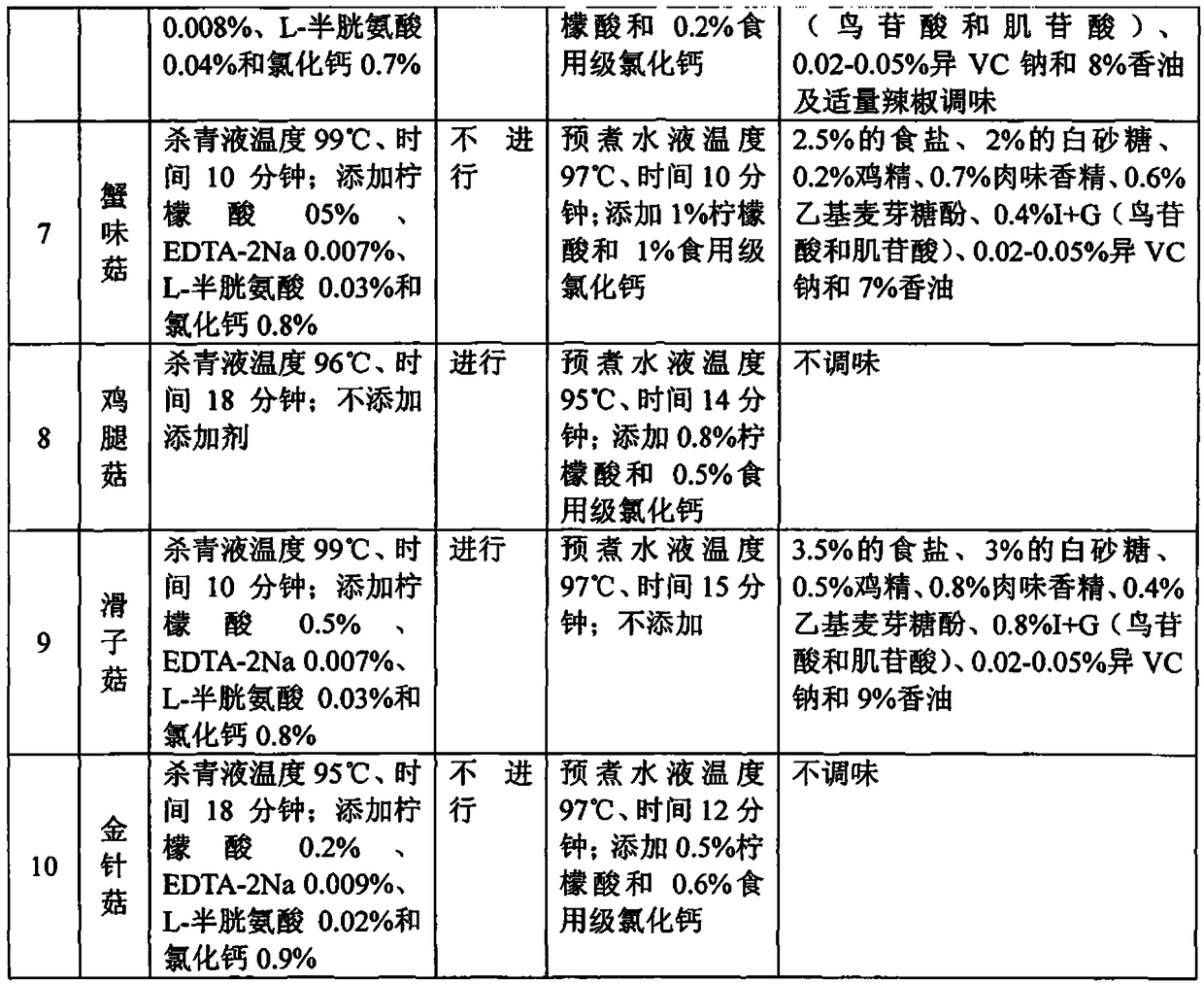

Examples

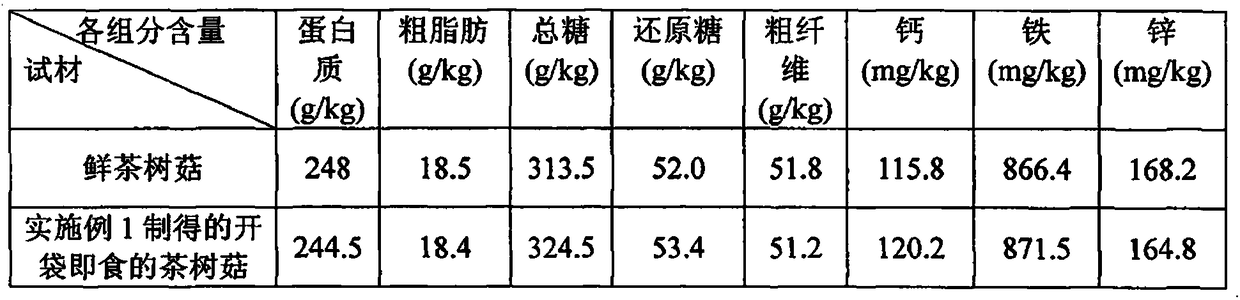

Embodiment 1

[0025] A kind of processing method of the instant tea tree mushroom of opening a bag, carries out as follows:

[0026] Finishing: Select fresh, mildew-free, uniform-sized tea tree mushrooms, remove the roots and feet, wash them with running water, and put them in 95-100°C with 0.5% citric acid, 0.02% EDTA-2Na, and L-cysteine 0.02% acid and 0.5% calcium chloride solution for 8-10 minutes, so that the temperature of the center of the bacteria reaches 95°C;

[0027] Cleaning and shaping: Take out the tea tree mushroom after killing green and cool it in cold water, tear it into strips along the longitudinal direction of the fungus, and control the length within 40-80mm;

[0028] Pre-cooking: put the above-mentioned cleaned and shaped tea tree mushroom into boiling water, add 0.5% citric acid and 0.5% salt-grade calcium chloride, and pre-cook for 15 minutes;

[0029] Dehydration: Put the above-mentioned precooked tea tree mushroom into the three-legged centrifuge for 25 minutes, a...

Embodiment 2

[0035] A kind of processing method of the ready-to-eat Flammulina velutipes in bag, carries out as follows:

[0036] Finishing: Select fresh, mildew-free, and uniformly sized Flammulina velutipes, remove the roots and feet, wash them with running water, and put them in 95-100°C with 0.5% citric acid, 0.005% EDTA-2Na, and L-cysteine 0.05% and 1% calcium chloride in the greening solution for 5-8 minutes, so that the temperature of the center of the bacteria reaches 95°C;

[0037] Cleaning and shaping: Take the above-mentioned enoki mushrooms out of cold water to cool them down, tear them into strips along the longitudinal direction of the bacteria, and control the length within 40-80mm; % citric acid, 0.1% salt grade calcium chloride, precooked for 8 minutes;

[0038] Dehydration: Put the above-mentioned precooked Flammulina velutipes into a three-legged centrifuge for 20 minutes, and dehydrate to 7.0%;

[0039] Seasoning: the above-mentioned Flammulina velutipes after dehydrati...

Embodiment 3

[0044] A kind of processing method of the ready-to-eat Pleurotus eryngii mushroom, carries out as follows:

[0045] Finishing: Select fresh, mildew-free, uniform-sized Pleurotus eryngii, remove the roots and feet, clean them with running water, and put them in 95-100°C with citric acid 0.8%, EDTA-2Na 0.01%, L-cysteine 0.03% amino acid and 0.6% calcium chloride solution for 15-20 minutes, so that the temperature of the center of the bacteria reaches 95°C;

[0046] Cleaning and shaping: Take out the above-mentioned Pleurotus eryngii after killing green and cool it in cold water, cut it into slices along the longitudinal direction of the bacteria, and control the length within 30-50mm; pre-cooking: put the above-mentioned Pleurotus eryngii after cleaning and shaping into boiling water , add 0.3% citric acid, 0.8% food grade calcium chloride, precook for 15 minutes;

[0047] Dehydration: Put the above-mentioned precooked Pleurotus eryngii into a three-legged centrifuge for 30 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com