In-situ optimization of titanium-containing blast furnace slag preparation method for photothermal coupling flue gas denitrification catalyst

A denitrification catalyst, photothermal coupling technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve difficult recycling, waste of resources, environmental pollution and other problems, to achieve the effect of simple and easy in-situ optimization process, uniform dispersion, and simple and easy reconstruction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

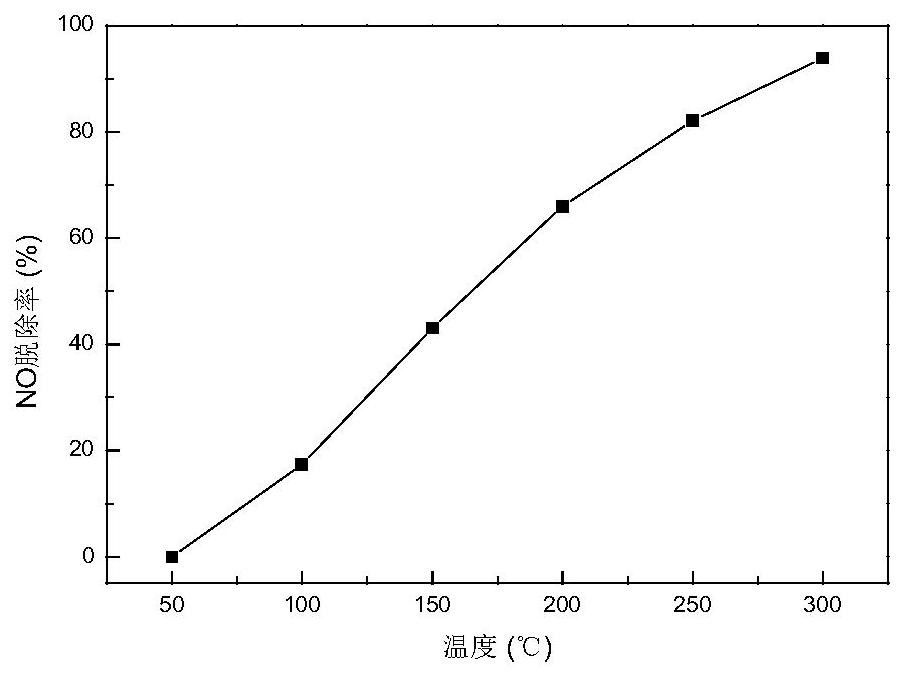

[0020] Embodiment 1: The titanium-containing blast furnace slag is crushed, powdered and dried for later use; 100g of titanium-containing blast furnace slag and 10g of MnO 2 The powder is placed in an agate mortar, ground and mixed evenly, placed in a crucible, heated in a box furnace to 1500°C for 1 hour and cooled in the furnace; the above MnO 2 The in-situ optimization slag is used as powder in a powder tank for standby; take 100g of the above-mentioned in-situ optimization slag and 30g Na 2 CO 3 The powder is mixed and ground evenly, placed in a crucible and kept at 1500°C for 1 hour, and cooled naturally for later use; after grinding the reconstituted slag powder tank, take 10.0091g of the powder and place it in 100mL of 8wt% hydrochloric acid solution at 30°C Stir for 60 minutes, filter to obtain the filter residue and filtrate, wash the filter residue with water, and dry to obtain the denitration catalyst.

Embodiment 2

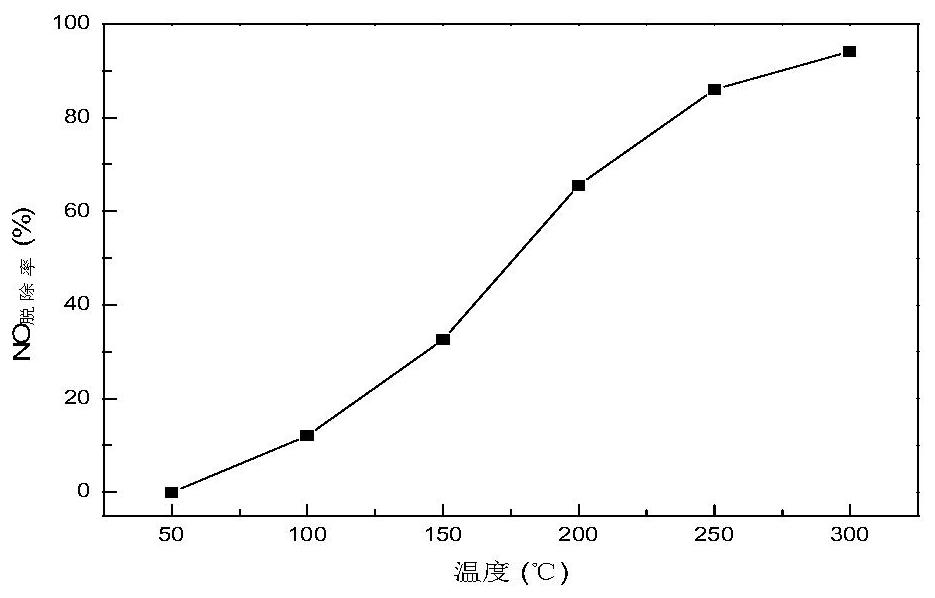

[0021] Embodiment 2: the titanium-containing blast furnace slag is crushed, powdered and dried for later use; 100g of titanium-containing blast furnace slag and 10g of MnO 2 The powder is placed in an agate mortar, ground and mixed evenly, placed in a crucible, heated in a box furnace to 1500°C for 1 hour and cooled in the furnace; the above MnO 2 The in-situ optimization slag is used as powder in a powder tank for standby; take 100g of the above-mentioned in-situ optimization slag and 30g Na 2 CO 3 The powder is mixed and ground evenly, placed in a crucible and kept at 1500°C for 1 hour, and cooled naturally for later use; after grinding the reconstituted slag powder tank, take 10.0068g of powder, place it in 150mL of 10wt% hydrochloric acid solution, and stir at 25°C After 60 minutes, the filter residue and filtrate were obtained by filtration, and the filter residue was washed with water and dried to obtain the denitration catalyst.

Embodiment 3

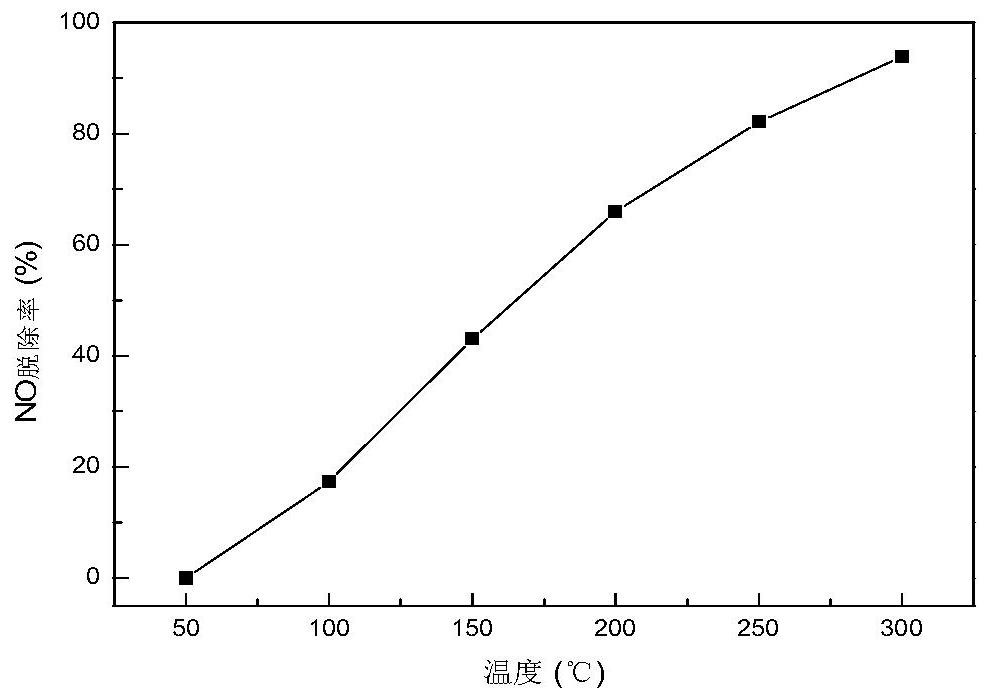

[0022] Embodiment 3: the titanium-containing blast furnace slag is crushed, powdered and dried for later use; 100g of titanium-containing blast furnace slag and 10g of MnO 2 The powder is placed in an agate mortar, ground and mixed evenly, placed in a crucible, heated in a box furnace to 1500°C for 1 hour and cooled in the furnace; the above MnO 2 The in-situ optimization slag is used as powder in a powder tank for standby; take 100g of the above-mentioned in-situ optimization slag and 30g of Na2CO 3 The powder is mixed and ground evenly, placed in a crucible and kept at 1500°C for 1 hour, and cooled naturally for later use; after grinding the reconstituted slag powder tank, take 10.0166g of powder, place it in 100mL of 8wt% hydrochloric acid solution, and stir at 30°C After 30 minutes, the filter residue and filtrate were obtained by filtration, and the filter residue was washed with water and dried to obtain the denitration catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| denitrification rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com