A kind of surface modification method of ballpoint pen

A technology of surface modification and ballpoint pen, which is applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of difficult processing of tungsten carbide hardness, reduced life of ballpoint pen, high processing cost, etc., and achieve low friction coefficient, The effect of increased hardness and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

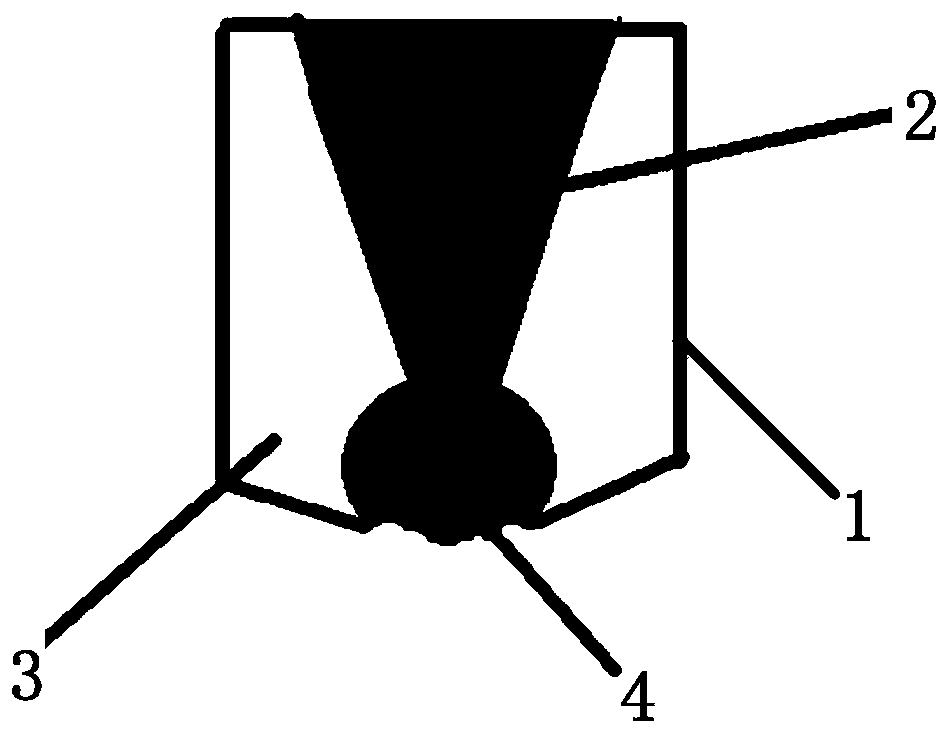

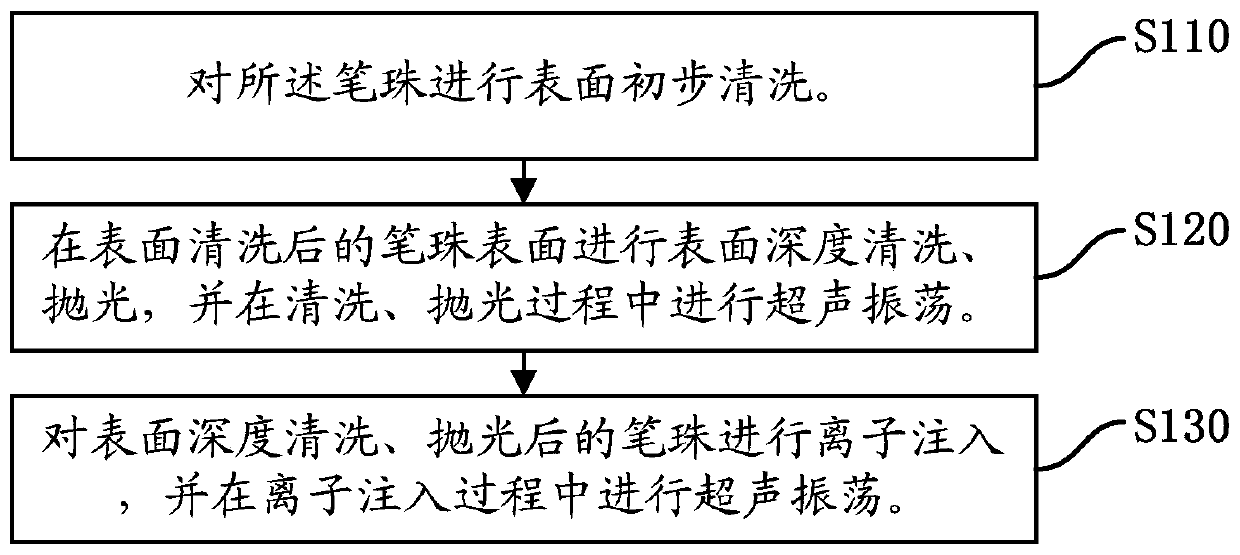

[0036] figure 1 The schematic diagram of the structure of the ballpoint pen refill provided by the embodiment of the present invention, such as figure 1 As shown, the refill of the ballpoint pen includes a refill body 1, pen ink 2, pen holder 3 and pen ball 4. During the writing process, the pen ball 4 is in direct contact with the paper surface to generate friction, so that the pen ball 4 is placed on the pen holder 3. Rolling inside brings out the pen and ink 3 in the refill body 1 to form handwriting. However, stainless steel has low hardness and is not wear-resistant, so that the life of the ballpoint pen with stainless steel as the base material for the "pen ball" is not high. This embodiment provides a surface modification method for the ball point pen ball. "Pen ball" for preliminary cleaning and deep cleaning, and then perform ion implantation to enhance the wear resistance of the stainless steel "pen ball" and improve the service life of the ballpoint pen. figure 2...

Embodiment 2

[0050] Select the "pen ball" with stainless steel as the base material, marked as Ball1, without surface modification, grind it against the untreated stainless steel sheet, measure its wear resistance, and then compare it with the ion-implanted pen ball and other The performance of the "pen ball" with tungsten carbide as the base material is compared, and the results are shown in Table 1. in, Figure 4 It is the optical topography of the surface of the pen ball magnified 400 times after the stainless steel "pen ball" without surface modification is ground against the stainless steel sheet.

Embodiment 3

[0052] Select the "pen ball" with stainless steel as the base material, marked as Ball2, and use the method provided in Example 1 to carry out surface modification treatment on it. The implementation steps are as follows:

[0053] S110, preliminary cleaning:

[0054] Ultrasonic cleaning was performed on the pen ball in absolute ethanol to initially remove the oil on the surface of the pen ball.

[0055] S120, deep cleaning, polishing:

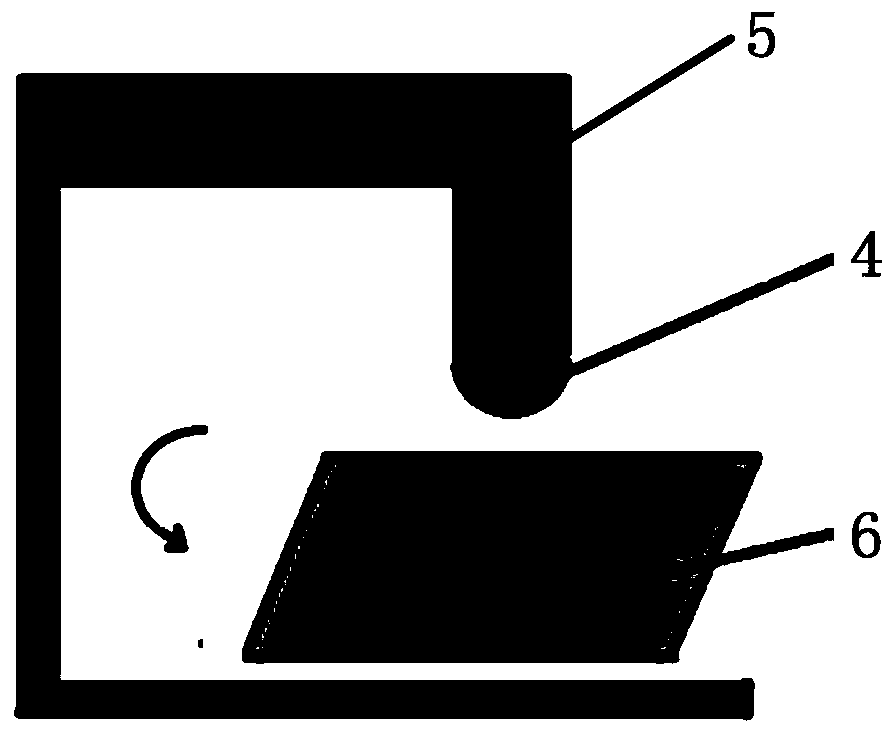

[0056] Put the pre-cleaned pen beads on the sample stage in the vacuum chamber, the Hall gas ion source cleans the surface of the pen beads, and the sample stage is accompanied by ultrasonic oscillation. The implantation conditions are: the beam current of the Hall gas ion source is 260mA, and the processing time is 26min.

[0057] S130, ion implantation:

[0058] Use MEVVA ion implantation equipment to perform surface ion implantation on the pen ball, the specific implanted element is C element, the implantation energy is 60KeV, and the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com