Concrete thixotropic agent and preparation method thereof

A thixotropic agent and concrete technology, used in the preparation of thixotropic agents and concrete thixotropic agents, can solve the problems that ordinary concrete cannot effectively maintain the shape, the design of the base plate does not meet the requirements, and the drainage slope cannot be smoothly realized. Ensure construction quality and service performance, significant technical economy, and the effect of improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

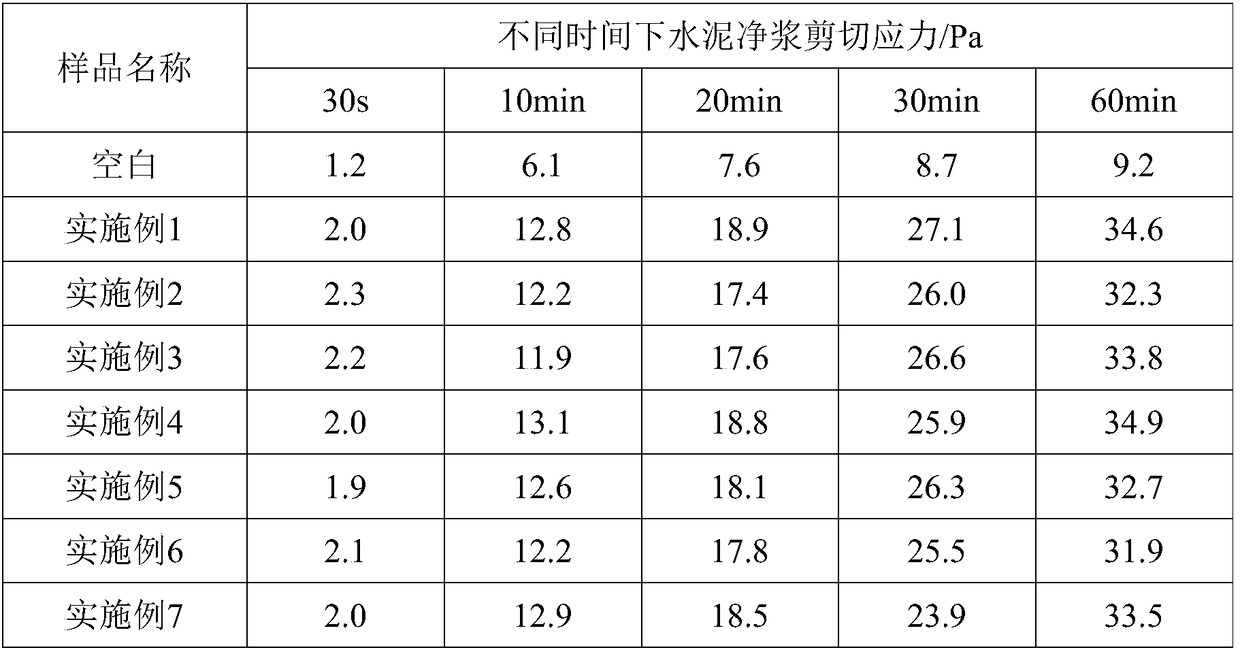

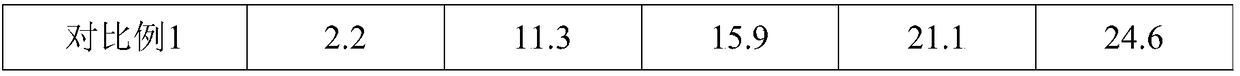

Examples

Embodiment 1

[0033] (1) Esterification: Add 226.0 parts of stearic acid and 183.8 parts of diethanolamine to a four-necked flask equipped with a thermometer, a stirrer, a constant pressure funnel, a nitrogen inlet tube, and a reflux condenser, and heat to 75°C to 80°C and stir Dissolve, add 0.62 parts of p-toluenesulfonic acid and 0.58 parts of phosphorous acid and continue to stir for 15 minutes; blow nitrogen to remove oxygen in the system; stir to reflux at 90°C to 100°C, react for 3 hours to 4 hours until no moisture is produced, stop The reaction results in an esterified intermediate.

[0034] (2) Quaternization: The temperature of the esterification intermediate is lowered to 65°C-70°C while stirring, and 85.8 parts of diethyl sulfate are added dropwise, and the dripping is completed at a constant speed within 25 minutes to 30 minutes; Heat at ~70°C for 3 hours to 3.5 hours; add 500 parts of water, stir and cool to 30°C.

[0035] (3) Preparation: Add 0.8 parts of fumed silica with a...

Embodiment 2

[0037] (1) Esterification: Add 148.4 parts of palmitic acid and 276.4 parts of triethanolamine into a four-neck flask equipped with a thermometer, a stirrer, a constant pressure funnel, a nitrogen inlet tube, and a reflux condenser, and heat to 70°C to 75°C and stir to dissolve , add 0.43 parts of p-toluenesulfonic acid and 0.47 parts of p-aminobenzenesulfonic acid and continue to stir for 15 minutes; blow nitrogen to remove the oxygen in the system; stir and heat up to 90°C to 95°C to reflux, and react for 3.5 hours to 4 hours until no moisture is produced , Stop the reaction to obtain the esterification intermediate.

[0038] (2) Quaternization: The temperature of the esterification intermediate is lowered to 60°C to 65°C while stirring, and 71.4 parts of diethyl sulfate is added dropwise, and the drop is completed at a constant speed within 20 minutes to 25 minutes; Heat at ~65°C for 3 hours to 3.5 hours; add 500 parts of water, stir and cool to 30°C.

[0039](3) Preparati...

Embodiment 3

[0041] (1) Esterification: Add 182.5 parts of myristic acid and 201.7 parts of diethanolamine into a four-neck flask equipped with a thermometer, a stirrer, a constant pressure funnel, a nitrogen inlet tube, and a reflux condenser, and heat to 60°C to 65°C and stir to dissolve , add 0.52 parts of p-aminobenzenesulfonic acid and 0.48 parts of phosphorous acid and continue to stir for 15 minutes; blow nitrogen to remove oxygen in the system; stir and heat up to 90°C to 95°C to reflux, react for 3 hours to 4 hours until no moisture is produced, stop The reaction results in an esterified intermediate.

[0042] (2) Quaternization: The temperature of the esterification intermediate is lowered to 50°C-60°C while stirring, and 110.0 parts of diethyl sulfate is added dropwise, and the drop is completed at a constant speed within 40 minutes to 50 minutes; Heat at ~60°C for 3.5 hours to 4 hours; add 500 parts of water, stir and cool to 30°C.

[0043] (3) Preparation: Add 2.2 parts of fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com