Method for preparing natural tocopherol succinate and refrigeration system thereof

A technology of tocopherol succinate and refrigeration system, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of loss of function, no longer biological activity of vitamin E, inconvenient preparation of vitamin E products, inconvenient storage, etc. Achieve the effect of high esterification rate, high purity and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

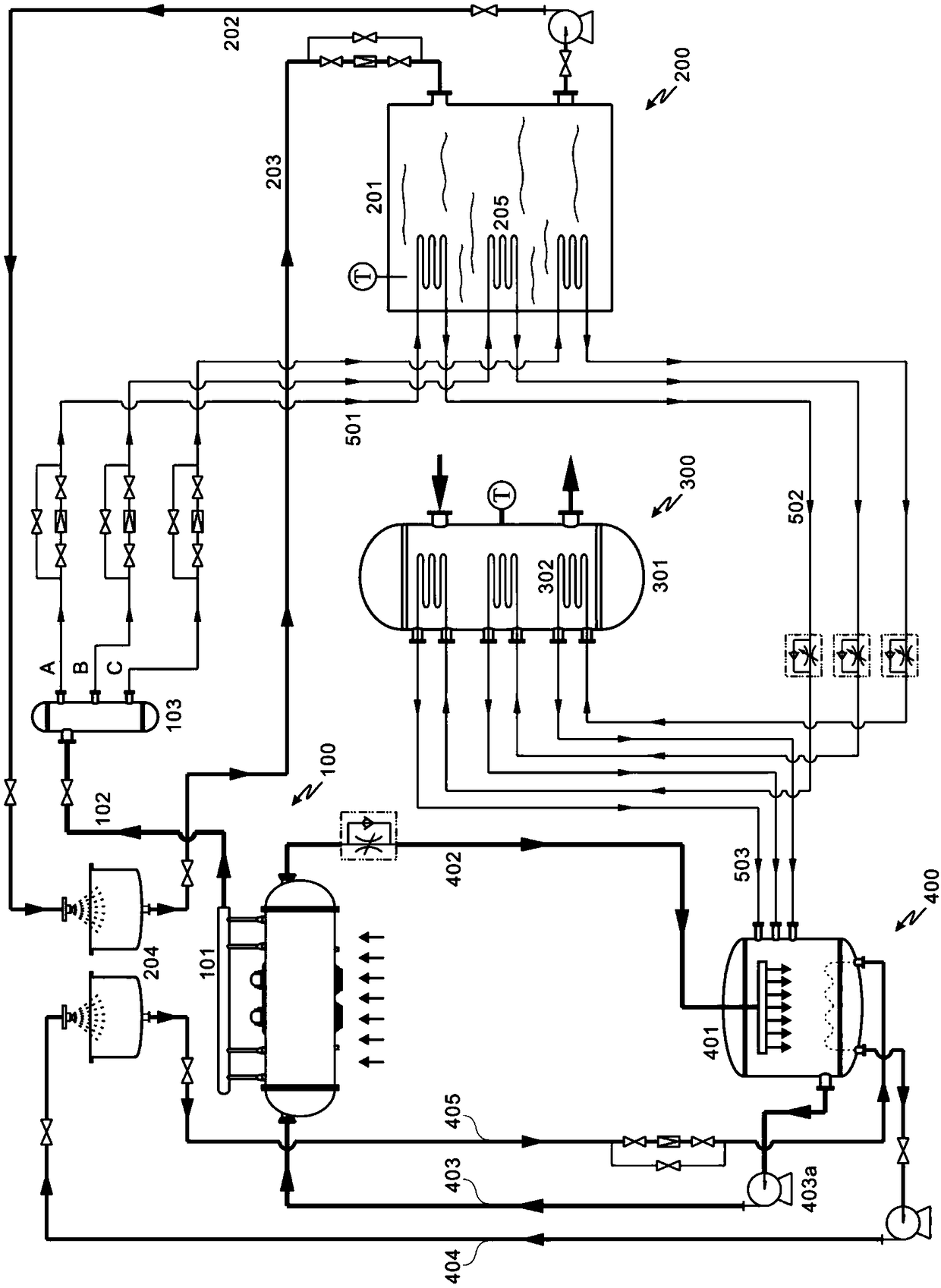

Image

Examples

Embodiment 1

[0028] Select the soybean deodorized distillate (the tocopherol content is 39.5%, and the specific rotation is 23.58°), add acetone to it, add 12ml of acetone per gram of the soybean deodorized distillate, and then treat it at -18°C for 45h. The measured tocopherol content increased to 54.6%.

[0029] To the deodorized distillate after acetone treatment, add succinic anhydride (addition is added according to 2.5 times of the molar amount of tocopherol in the deodorization distillate after acetone treatment), then add pyridine (addition is after every kilogram of acetone treatment Add 100ml of the deodorized distillate), and then react at 50°C for 2.5h to obtain the crude product of natural tocopherol succinate.

[0030] The prepared crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 6ml / g, and crystallized at 2°C for 20h.

[0031] The product was tested, and the specific optical rotation of vitamin E in the produ...

Embodiment 2

[0033] Select the soybean deodorized distillate (the tocopherol content is 39.5%, and the specific rotation is 23.58°), add acetone to it, add 10ml of acetone per gram of the soybean deodorized distillate, and then treat it at -20°C for 40h. The measured tocopherol content increased to 53.9%.

[0034] To the deodorized distillate after acetone treatment, add succinic anhydride (addition is added according to 3 times of the molar amount of tocopherol in the deodorization distillate after acetone treatment), then add pyridine (addition is after every kilogram of acetone treatment Add 80ml of the deodorized distillate), and then react at 40°C for 2.5h to obtain natural tocopheryl succinate.

[0035] The obtained crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 7ml / g, and crystallized at 4°C for 16h.

[0036] The product was tested, and the specific optical rotation of vitamin E in the product was 23.76°, the activ...

Embodiment 3

[0038] Select the soybean deodorized distillate (the tocopherol content is 39.5%, and the specific rotation is 23.58°), add acetone to it, add 10ml of acetone per gram of soybean deodorized distillate, and then treat it at -17°C for 45h. The measured tocopherol content increased to 54.1%.

[0039]To the deodorized distillate after acetone treatment, add acetic anhydride (addition is added according to 2.5 times of the molar amount of tocopherol in the deodorization distillate after acetone treatment), then add pyridine (addition is after every kilogram of acetone treatment Add 90ml of the deodorized distillate), and then react at 40°C for 3h to obtain natural tocopheryl succinate.

[0040] The prepared crude natural tocopheryl succinate was crystallized with n-hexane, the amount of n-hexane / tocopheryl succinate was 6ml / g, and crystallized at 4°C for 18h.

[0041] The product was tested, and the specific optical rotation of vitamin E in the product was 23.69°, the active ingre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific rotation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com