Method for preparing diglyceride through enzyme catalysis of ester exchange of monoglyceride and medium chain triglyceride

A technology for triglyceride esters and diglycerides, which is applied in the field of enzymatically catalyzed transesterification of monoglycerides and medium-chain triglycerides to prepare diglycerides, which can solve problems such as poor practicability, lack of energy saving and environmental protection, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

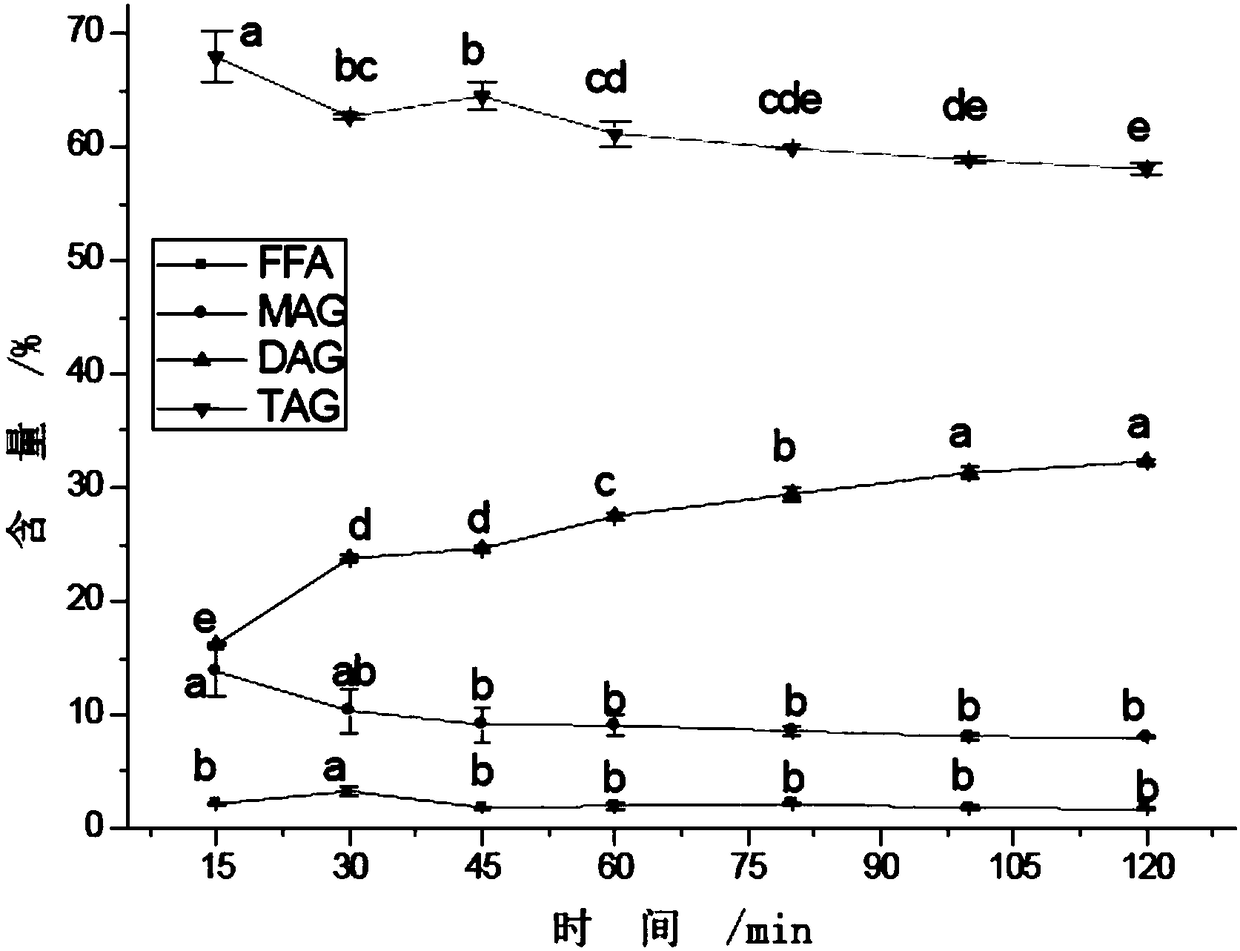

[0070] A method for preparing diglycerides by enzymatically catalyzing the transesterification of monoglycerides and medium-chain triglycerides, comprising the following steps:

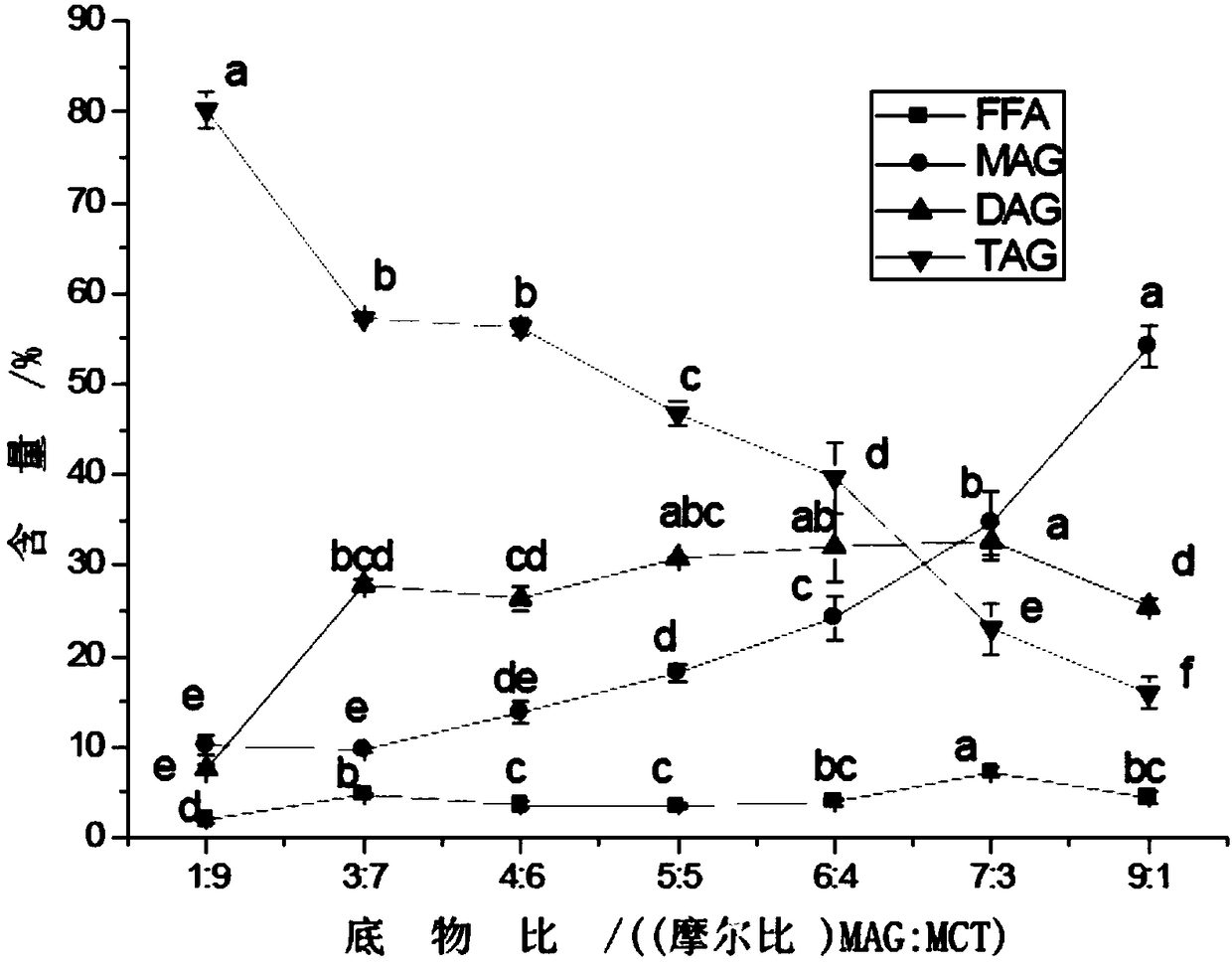

[0071] (1) Take a certain amount of long-chain fatty acid monoglycerides and add them to the rotary evaporator, set the temperature of the water bath to 80°C, add a certain amount of medium-chain fatty acid triglycerides after the long-chain fatty acid monoglycerides are melted, mix well, The mol ratio of the long-chain fatty acid monoglyceride and medium-chain fatty acid triglyceride added wherein is 7:3;

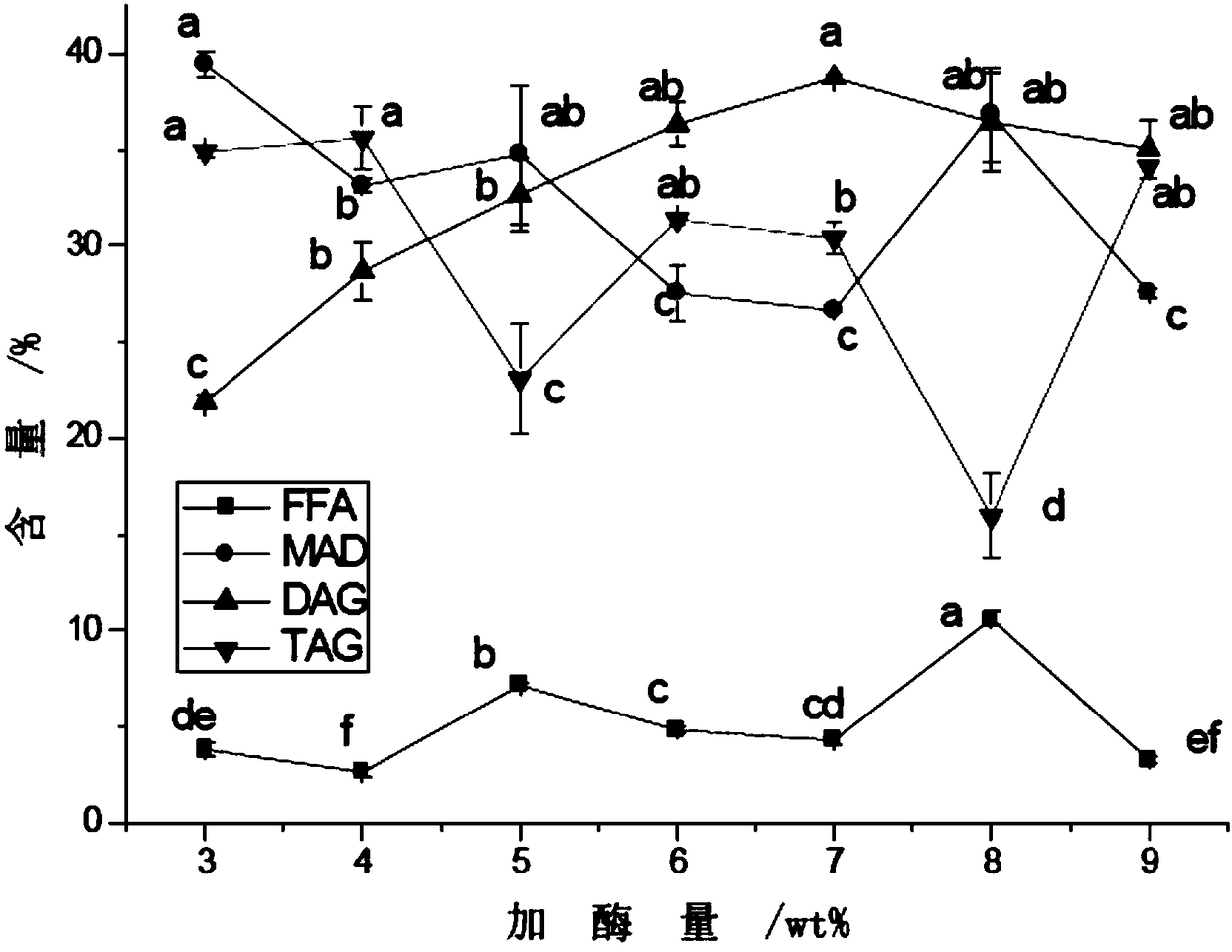

[0072] (2) Adjust the temperature of the water bath to be 60°C, add the immobilized lipase Lipozyme TL IM with a weight percentage of 8% (based on the total mass of the substrate), and carry out the reaction under vacuum conditions, and the rotating speed of the rotary evaporator is 100r / min, the transesterification reaction time is 100min, and the crude diglyceride product is obtained.

[0073]...

Embodiment 2

[0075] A method for preparing diglycerides by enzymatically catalyzing the transesterification of monoglycerides and medium-chain triglycerides, comprising the following steps:

[0076] (1) Take a certain amount of long-chain fatty acid monoglycerides and add them to the rotary evaporator, set the temperature of the water bath to 80°C, add a certain amount of medium-chain fatty acid triglycerides after the long-chain fatty acid monoglycerides are melted, mix well, The mol ratio of the long-chain fatty acid monoglyceride and medium-chain fatty acid triglyceride added wherein is 3:7;

[0077] (2) Adjust the temperature of the water bath to be 65° C., add the immobilized lipase Lipozyme TL IM that is 3% by weight (based on the total mass of the substrate), and the reaction is carried out under vacuum conditions, and the rotating speed of the rotary evaporator is 100r / min, the transesterification reaction time is 15min, and the crude diglyceride product is obtained.

[0078] Gly...

Embodiment 3

[0080] A method for preparing diglycerides by enzymatically catalyzing the transesterification of monoglycerides and medium-chain triglycerides, comprising the following steps:

[0081] (1) Take a certain amount of long-chain fatty acid monoglycerides and add them to the rotary evaporator, set the temperature of the water bath to 80°C, add a certain amount of medium-chain fatty acid triglycerides after the long-chain fatty acid monoglycerides are melted, mix well, The mol ratio of the long-chain fatty acid monoglyceride and the medium-chain fatty acid triglyceride wherein added is 4:6;

[0082] (2) Adjust the temperature of the water bath to be 75°C, add the immobilized lipase Lipozyme TL IM that is 4% by weight (based on the total mass of the substrate), and the reaction is carried out under vacuum conditions, and the rotating speed of the rotary evaporator is 100r / min, the transesterification reaction time is 30min, and the crude diglyceride product is obtained.

[0083] G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com